Page 8 of 26

7/9/19

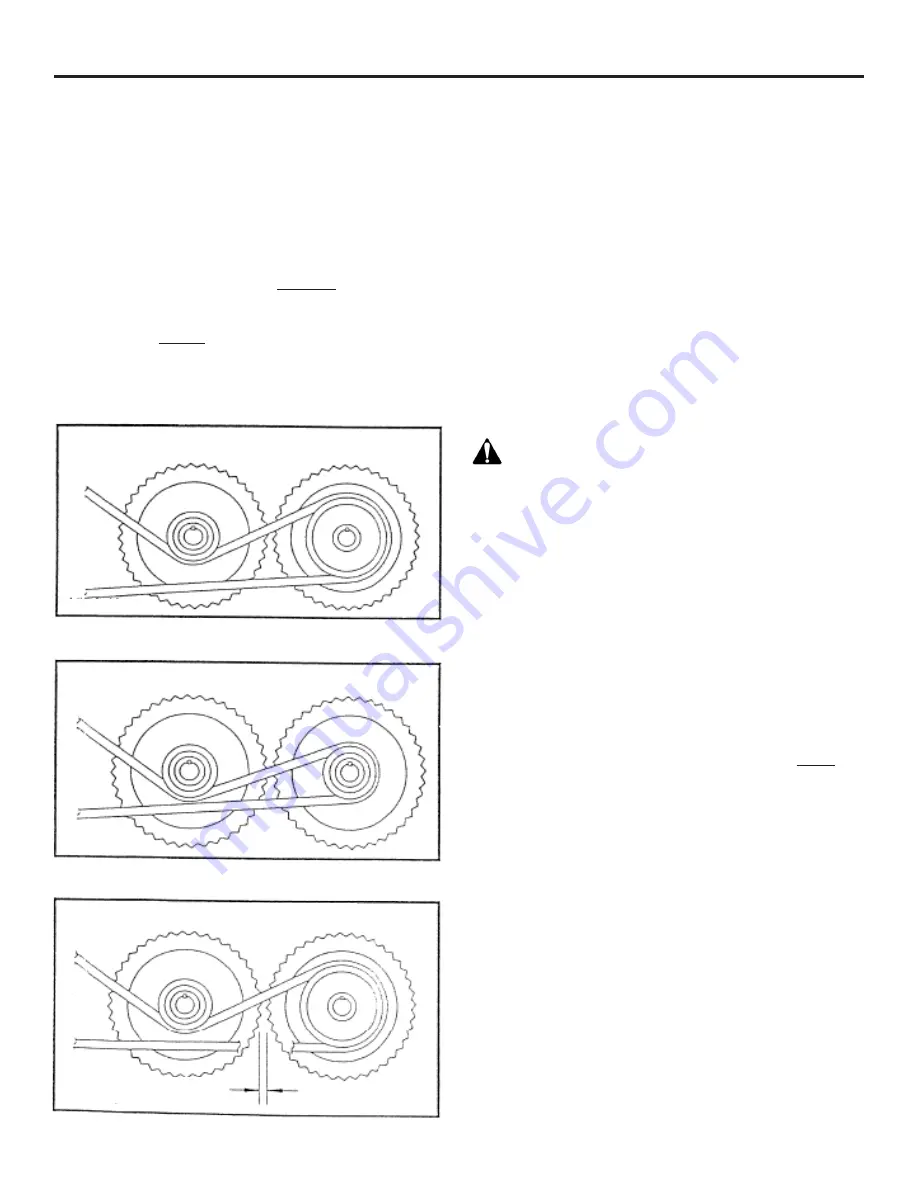

Figure 4

Figure 5

Figure 6

OPERATION / MAINTENANCE

OPTIONAL ROLL CONFIGURATION - This roller mill

is available with five different roll configurations and

comes standard with a differential drive (See Figure 4).

Corrugation numbers refer to the number of corrugations

or “teeth” per inch. The larger the corrugation number,

the smaller the particle size produced. Changing the roll

gap is the next preferred method for adjusting particle

size. (See Adjusting Rolls section, page 6) In addition,

feed consistency, or particle size, may be adjusted by

changing the relative drive roll and idler speeds. This

is accomplished by replacing the drive roll pulley with

a pulley the same size as that of the idler roll. (See

Figure 5). However, when the drive method is changed,

it will generally reduce the capacity of the mill and

not allow as fine a particle size. Consult your dealer, or

Automatic Equipment for recommendations regarding roll

configuration by any other method than those approved

by Automatic Equipment will void the warranty.

MAINTENANCE - Automatic roller mills are manufactured

from the best materials and workmanship available.

Simple adjustments and minimum maintenance have been

emphasized in their engineering. Although all components

of your roller mill are tested and properly adjusted

before it leaves the factory, some may require additional

adjustment after a break in period.

After your roller mill has been in operation for a few hours,

examine the entire machine for loose bolts, set screws,

lock collars, belts, etc. This initial check is an important

first step in an ongoing program for keeping your roller

mill in top running condition and should be performed

periodically as part of the general maintenance of your

roller mill. Like any other implement, your roller mill

requires proper care and intelligence in operation. Misuse

and/or neglect will only cause unnecessary expense and

dissatisfaction.

WARNING: SHIELDS AND GUARDS ARE PROVIDED

FOR YOUR PROTECTION. Although some shields and

guards may need to be removed or opened for servicing

and adjustments, they should always be replaced or

closed before operation resumes.

BELTS - All belts should be inspected for proper

alignment and tension after a few hours of operation.

Tension should be measured between the motor and flat

pulley. The belt should deflect 3/16” using approximately

60 pounds of force. Periodic checks of all belts should be

made to ensure proper alignment, correct tension levels

and to detect worn or deteriorating belts.

PULLEY SET SCREW ADJUSTMENT - The belt drive

system on your roller mill includes several pulleys which

use a setscrew to hold them in place on the key. ONLY

“Cup Point” set screws with knurled tips should be used.

To correctly seat the set screw, turn it “IN” and “OUT”

several times before tightening in place. This will wear a

groove in the key for the setscrew to seat in.

ROLLER TENSION SPRINGS - The roller tension springs

on the idler roll are set at the factory to maintain the

correct amount of pressure. They should be 4 1/2” long

±1/8”. The springs allow the rolls to separate so foreign

objects such as nails, bolts, stones, gravel, etc. may

pass between the rolls. A magnetic grate is standard

on the roller mill and should remove most of the metal

items, but in the event that something gets through, the

spring action will help prevent the roll teeth from being

damaged. If the rolls become out of alignment and require

readjustment, the springs may require similar adjustments.

(See Realigning Rolls, Page 8)

DIFFERENTIAL DRIVE

Idler (left)

SAME SPEED DRIVE

Idler (left)

ROLL SPACING

.015”

Idler (left)