16

P03

Low

pressure

protection

1.Lack of gas;

2.Refrigerant system block

;

3.Exceed

heat

pump

operation range.

1.Check if gas system is leaking;

2.Check if filter is blocked;

3.Check ambient Temp. and water temp.

is over limitation.

1.Amend the leakage

and

reinject the gas;

2.change a new filter.

P04

T3 Coil over heat

protection

1.Heat Pump fan blowing

area is blocked;

2.Evaporator is blocked;

3.T3 coil sensor position

was changed.

1.Check if the blowing area is open;

2.Check if the evaporator is blocked;

3.Check if the coil snesor resistance value

is correct.

1.Put away the blow area;

2.Clean the evaporator;

3.Change a new sensor.

P05

Exhausting

gas

temperature

protection

1Lack of gas;

2.sensor

position

was

changed.

1.

Ceheck if refrigerant system is leaking;

2.

Check if the snesor resistance value is

correct.

1.Amend the leakage and reinject the

gas;

2.Change a new sensor.

P06

Outlet

water

temperature

anti-freezing

protection

1.

lower water flow;

2.

heat

exchanger

blocked;

3.

Y-shaped filter blocked

;

4.

Overlow load.

1.

check if air exists in water system;

2.

Plate heat exchanger if blocked;

3.

check if Y-shaped filter has block;

4.

check design of indoor water system if

reasonable,if have water bypass.

1.If drain valve has problem,change

a new one;

2.Blow plate heat exchanger with

water or high-pressure gas through

reverse direction;

3.Clean Y-shaped filter;

4.Water system must have bypass.

P07

Pipe

temperature

anti-freezing

protection

1.

sytem lack of gas;

2.

water

sytem

has block;

3.

cooling system has

block.

1.

Check system if any leakage;

2.

Check Y-shaped filter has block;

3.

Check if cooling system filter has block.

1.Fix leakage and re-charge gas

;

2.Clean Y-shaped filter

;

2.Change filter.

P08

High-pressue

2

protection

High pressure switch 2

cuts

Check if high pressure switch 2 cuts

under unit OFF condition

Change high pressure switch 2

E01

Controller

communication

failure

Communication

cable cuts

Check communication cable if cut

Change connection cable or

re-connect

E02

TP1 exhaust gas

temperature

sensor failure

sensor temperature

deviation or

cuts

Check sensor resistance value or if

sensor cuts

Change sensor or re-connect

cable

E03

T3

coil

temperature

sensor failure

sensor temperature

deviation or cuts

Check sensor resistance value or if

sensor cuts

Change sensor or re-connect

cable

E04

T4

ambient

temperature

sensor failure

Ensor temperature

deviation or cuts

Check sensor resistance value or if

sensor cuts

Change sensor or re-connect

cable

E05

T5 liquid gas

temperature

sensor

sensor temperature

deviation or cuts

Check sensor resistance value or if

sensor cuts

Change sensor or re-connect

cable

E06

TH return gas

temperature

sensor failure

sensor temperature

deviation or cuts

Check sensor resistance value or if

sensor cuts

Change sensor or re-connect

cable

E07

TW water tank

temperature

sensor failure

sensor temperature

deviation or cuts

Check sensor resistance value or if

sensor cuts

Change sensor or re-connect

cable

E08

T6 inlet water

temperature

sensor failure

sensor temperature

deviation or cuts

Check sensor resistance value or if

sensor cuts

Change sensor or re-connect

cable

E09

T7 outlet water

temperature

sensor failure

sensor temperature

deviation or cuts

Check sensor resistance value or if

sensor cuts

Change sensor or re-connect

cable

E10

Controller

and

Drive

PCB

Communicate

failure

Communication

cable cuts

Check communication cable if cut

Change connection cable or

re-connect

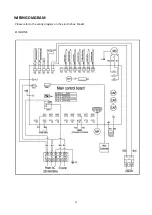

Содержание Eco Full Inverter EFI 14

Страница 1: ...0 EFI Series Heat Pumps Installation and Operation Manual Eco Full Inverter Swimming Pool Heat Pump ...

Страница 2: ...0 ...

Страница 4: ...1 ...

Страница 25: ...21 WIRING DIAGRAM Please refer to the wiring diagram on the electricbox Model EFI14 17 23 ...

Страница 28: ...24 ...

Страница 29: ...25 User Manual for APP Application EFI Full Inverter Series ...