AUBER INSTRUMENTS

WWW.AUBERINS.COM

2021.05

P2/7

4.1 Sensor connection

4.1.1 Thermocouple

The thermocouple should be connected to terminals 9 and 10. Make sure that

polarity is correct. There are two commonly used color codes for the K type

thermocouple. US color code uses yellow (positive) and red (negative). Imported

DIN color code uses red (positive) and green/blue (negative). The temperature

reading will decrease as temperature increases if the connection is reversed.

4.1.2 RTD sensor

For a three-wire RTD with standard DIN color code, the two red wires should be

connected to the terminals 9 and 10. The white wire should be connected to

terminal 8. For a two-wire RTD, the wires should be connected to terminals 8 and

9. Jump a wire between terminals 9 and 10.

For PT100 sensor, set Input Sensor Type,

Inty

, to

“

P100

”

(1 degree resolution)

or

“

P10.0

”

(0.1 degree resolution).

4.2 Power to the controller

The power cables should be connected to terminals 1 and 2. Polarity does not

matter. It can be powered by 85 - 260 V AC or DC power source. Neither a

transformer nor jumper is needed to wire it up. For the sake of consistency with

the wiring example described later, we suggest you connect the hot wire to

terminal 2 and neutral to 1. Since the controller is in a plastic shell, ground wire is

unnecessary.

4.3 Output connection

Three control output options are offered by this controller: (1) Linear current

output provides 0 ~ 20 mA or 4 ~ 20mA current output. (2) J1 relay output can be

used to turn on a contactor or a solenoid valve. It can also drive a small heater

directly if the heater draws less 3 Ampere.

4.3.1 Drive the load through linear current output (mA)

Connect terminal 7 to the negative input and terminal 6 to the positive input of the

loads which takes linear input (like linear controlled valve). Set the Control Output

Mode (

outy

) to 1, 2, or 5 depending on the control mode to be used. Then set

the Main Output Mode (

Coty

) to “0

-

20” or “4

-

20”.

See Figure

12 for an example.

Please note that the SSR output is not available on this model.

4.3.2 Drive the load through J1 relay

Assuming the controller is powered by a 120 V AC source and the contactor has

a 120 V AC coil, jump a wire between terminal 2 and 4. Connect terminal 5 to one

lead of the coil and terminal 1 to the other lead of the coil. Set the system Control

Output Mode (

outy

) to 3 or 4 depending on the control mode to be used. Please

see Figure 10 for an example.

4.4 Note for first time users

For first time users with no prior experience with PID controllers, the

following notes may prevent you from making a few common mistakes.

4.4.1

Power to the heater does not flow through terminal 4 and 5 of the controller.

The controller consumes less than 2 watts of power. It only provides a control

signal to the relay. Therefore, 20 gauge wires are sufficient for providing power to

terminal 1 and 2. Thicker wires may be more difficult to install.

4.4.2

The J1 relay is

“dry single pole switch”.

It does not provide power by itself.

Figure 11 shows how the J1 relay is wired to pass the 120 V AC power to drive an

external contactor which requires 120 V AC for its coil. If the coil of the contactor

requires a different voltage than the power supplied to the controller, an additional

power source will be needed (Please see Figure 11 for an example).

5. Parameter Settings

For safety reasons, control parameters are divided into three groups with different

pass codes. You should only give the code to those who have the responsibility

and knowledge of how to properly change it. Code 0089 contains parameters for

system configuration that may need to be changed during the initial set up. Code

0036 contains parameters for tuning the control performance. Code 0001 is for

changing set temperature and alarm settings.

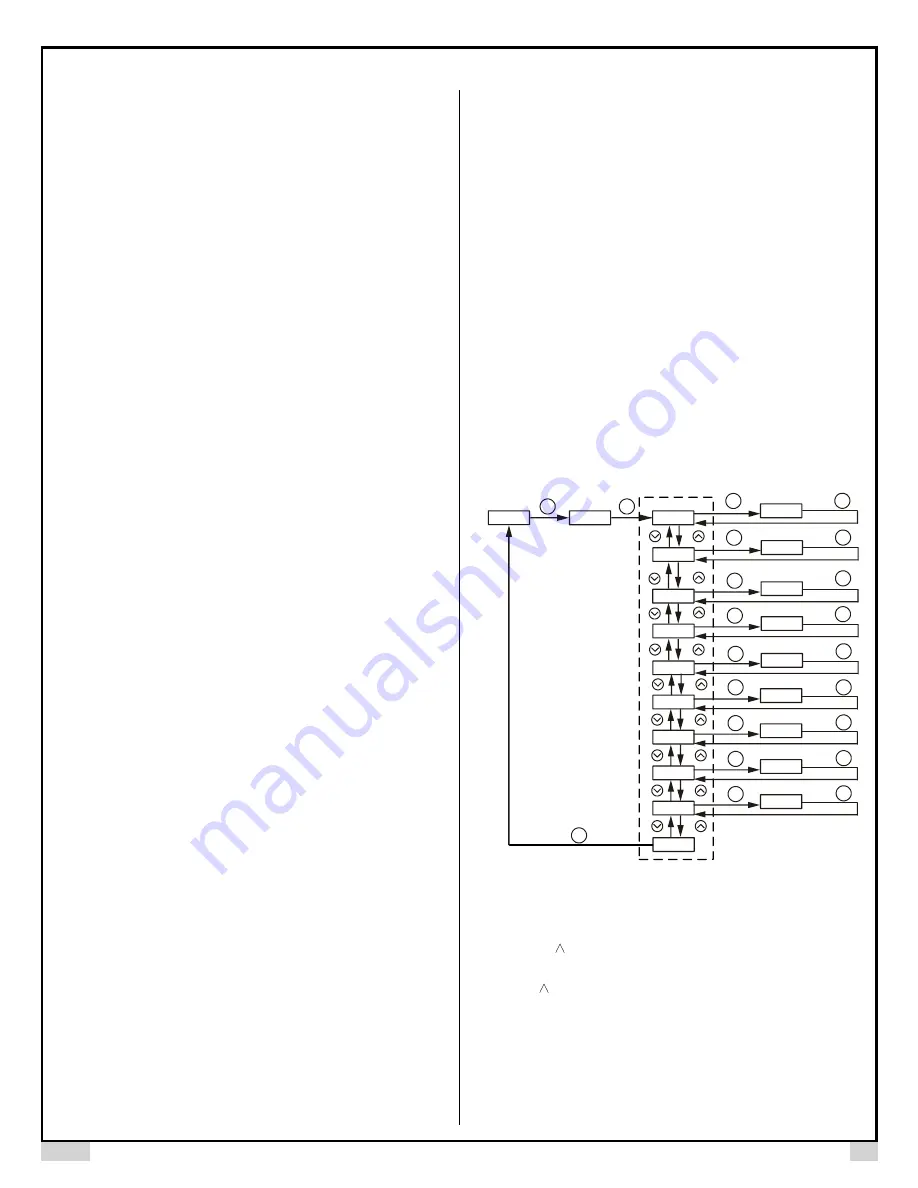

5.1 System configuration parameters (accessed by code 0089)

The system configuration parameters are listed in Table 1.

To change the

parameters, press SET key briefly, enter the

code “0089”

and press SET key

again. The procedures to change system parameters are shown in the flow chart

in Figure 3.

Operation Mode

0089

Enter Code

Parameter Display

Control output mode

inty

X

XXXX

X

XXXX

outy

hy

psb

Main output mode

Input offset

SET

SET

SET

SET

SET

SET

SET

X

rd

Control function

SET

X

corf

Display unit(C/F)

end

SET

SET

SET

SET

SET

Input sensor type

XXXX

SET

SET

XXXX

coty

SET

Hysteresis band

SET

SET

XX

id

Unit ID

SET

SET

XXXX

baud

Baud rate

SET

Figure 3. System parameters setup flow chart.

(1) Press SET key to enter setting mode;

(2) Press >, V, or key to adjust parameters;

(3) Press SET key to confirm;

(4) Press V or

key to select the new parameter and repeat step 2 and 3.

(5) Go to “End”, press SET key to exit parameter setting mode.