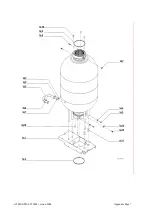

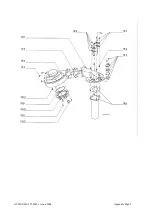

Atmos Multi Mk 2 Parts List

Atmos Multi 24/80

Atmos Multi 24/80 PLUS

Atmos Multi 32/80 PLUS

Drg Ref Description

Part

Ref.

17 Thermostat

*

*

*

78.76.54.981

18 Rear

insulation

*

*

*

07.98.83.229

19

Burner/fan assembly - 24 Model

*

*

07.95.25.003

19

Burner/fan assembly - 32 Model

*

07.95.25.004

19.1 Burner

casting

*

*

*

07.95.07.002

19.2 Fan

casing

*

*

*

07.98.83.185

19.3 Fan

*

*

*

07.98.36.003

19.4

Nut M4

*

*

*

07.98.82.080

19.5

Viewing glass set

*

*

*

07.95.26.003

19.6 Burner

set

*

*

*

07.95.25.002

19.7

Ionisation probe set

*

*

*

07.95.78.004

19.8

Ignition electrode set

*

*

*

07.95.70.006

19.9 O-Ring

80x2

*

*

*

07.98.83.184

19.10

Mixing chamber 25 mm - 24 Model

*

*

07.98.16.002

19.10

Mixing chamber 28 mm - 32 Model

*

07.98.16.001

19.11

Screw M6x8

*

*

*

07.98.82.082

19.12

Grommet 15 mm

*

*

*

07.98.68.041

19.13

Nipple cover Ø 6 mm

*

*

*

07.98.15.092

20 Ceramic

core

*

*

*

07.98.27.001

21 Mid

baffle

*

*

*

07.98.41.027

22 Lower

baffle

*

*

*

07.98.41.016

23 Condensate

collector

*

*

*

07.98.07.007

24

Siphon 32x140 mm

*

*

*

07.90.74.200

25

Sealing washer 60 mm

*

*

*

07.98.83.233

26

Lifting bar set

*

*

*

07.95.74.023

27

CH pump (inc. cable loom K5)

*

*

*

07.95.36.002

28

3 Port valve (inc. cable loom K7)

*

*

*

75.83.01.004

29

Return pipe for CH pump

*

*

*

07.98.74.284

30 Pressure

sensor

*

*

*

07.98.78.004

31

Pump seal 30 mm

*

*

*

07.98.83.230

32

Union nut 1"

*

*

*

07.98.82.113

33

Short pipe for pump

*

*

*

07.98.74.288

34

T-piece 22x22x22 mm

*

*

*

07.98.74.304

35

Pipe with bend - pump

*

07.98.74.296

35

Pipe with bend – helix coil

* *

07.98.74.287

36

Elbow connection 22x22 mm

* *

74.64.30.958

37 Front

insulation

*

*

*

07.98.83.228

38 Flow

pipe

*

*

*

07.98.74.308

39 Bracket

*

*

*

07.98.37.042

40 Ignition

transformer

*

*

*

07.98.61.001

41

Screw M4x8 self tap

*

*

*

82.08.93.046

42

Hex bolt M8x12

*

*

*

07.98.82.112

43

Controller mounting plate

*

*

*

07.95.30.001

44 Controller

*

*

*

07.95.64.001

45

Controller front plate

*

*

*

07.98.35.288

46

Front case set

*

*

*

07.95.22.004

47

Data Plate 24 Model

*

07.98.35.294

47

Data Plate 24 Plus Model

*

07.98.35.295

ATMOS MULTI Mk2 version 2004

Appendix Page 3

Содержание Multi Mk2

Страница 1: ...APPENDIX ATMOS MULTI Mk2 version 2004 Appendix Page 1 ...

Страница 5: ...ATMOS MULTI Mk2 version 2004 Appendix Page 5 ...

Страница 6: ...ATMOS MULTI Mk2 version 2004 Appendix Page 6 ...

Страница 7: ...ATMOS MULTI Mk2 version 2004 Appendix Page 7 ...

Страница 8: ...ATMOS MULTI Mk2 version 2004 Appendix Page 8 ...

Страница 9: ...ATMOS MULTI Mk2 version 2004 Appendix Page 9 ...