AVR

®

In System Programmer User Guide

3-1

Section 3

Hardware Description

3.1

General Board

Description

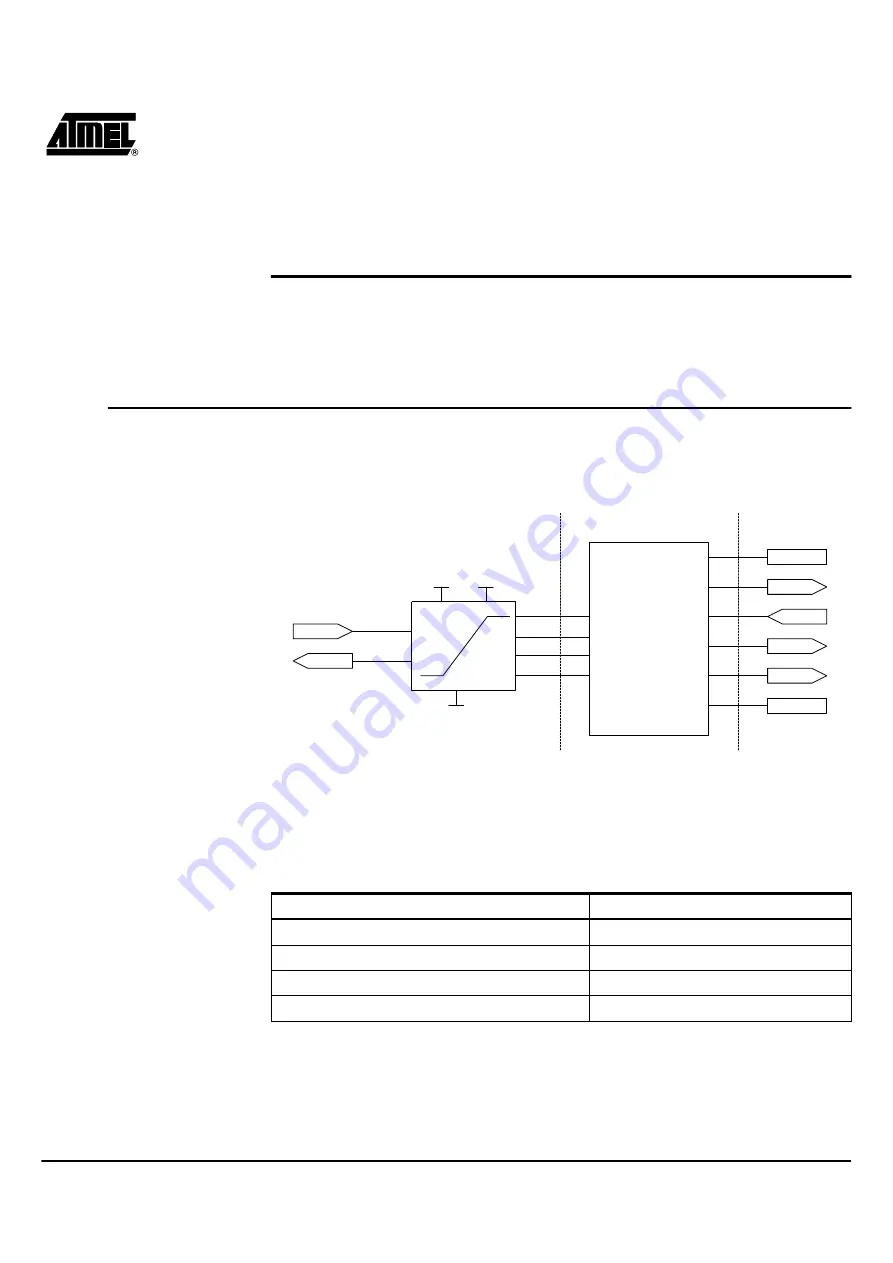

A block diagram of the AVRISP is shown in Figure 3-1. The AVRISP can be divided in

three sections: The RS-232 interface, the Control section and the ISP cable. In this sec-

tion a brief overview of the different blocks will be given.

Figure 3-1. Simplified AVRISP Block Schematics

3.1.1

RS-232 Serial

Interface

The AVRISP uses a standard female DSUB, RS-232 port for communication with the

front-end software (AVR Studio). It supports communication of 115200 baud.

3.1.2

Control Section

The control MCU handles all communication between the target AVR and the front-end

software. The AVRISP is completely software controlled from AVR Studio. No manual

configuration of the ISP is needed.

A 3-color LED indicates the status of the AVRISP. During programming the LED is yel-

low. When the target AVR is successfully programmed, the LED will turn green. If

programming fails, the LED will turn red to indicate that programming (or verification)

CTRL

MCU

RxD

TxD

GND

VTG

RESET

SCK

MOSI

MISO

RS-232

Level

VTG

VTG

GND

RxD

TxD

RS-232 Interface

Control Section

ISP Cable

Table 3-1. Status Led

Led Color

Description

Red-Yellow-Green-Off-Green Cycle

Power on Sequence

Yellow

Busy – Programming

Red

Programming Failed

Green

Ready – OK

Содержание AVR ISP

Страница 1: ...ISP User Guide ...

Страница 2: ......

Страница 8: ...Getting Started 2 2 AVR In System Programmer User Guide ...