- 32 -

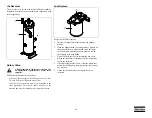

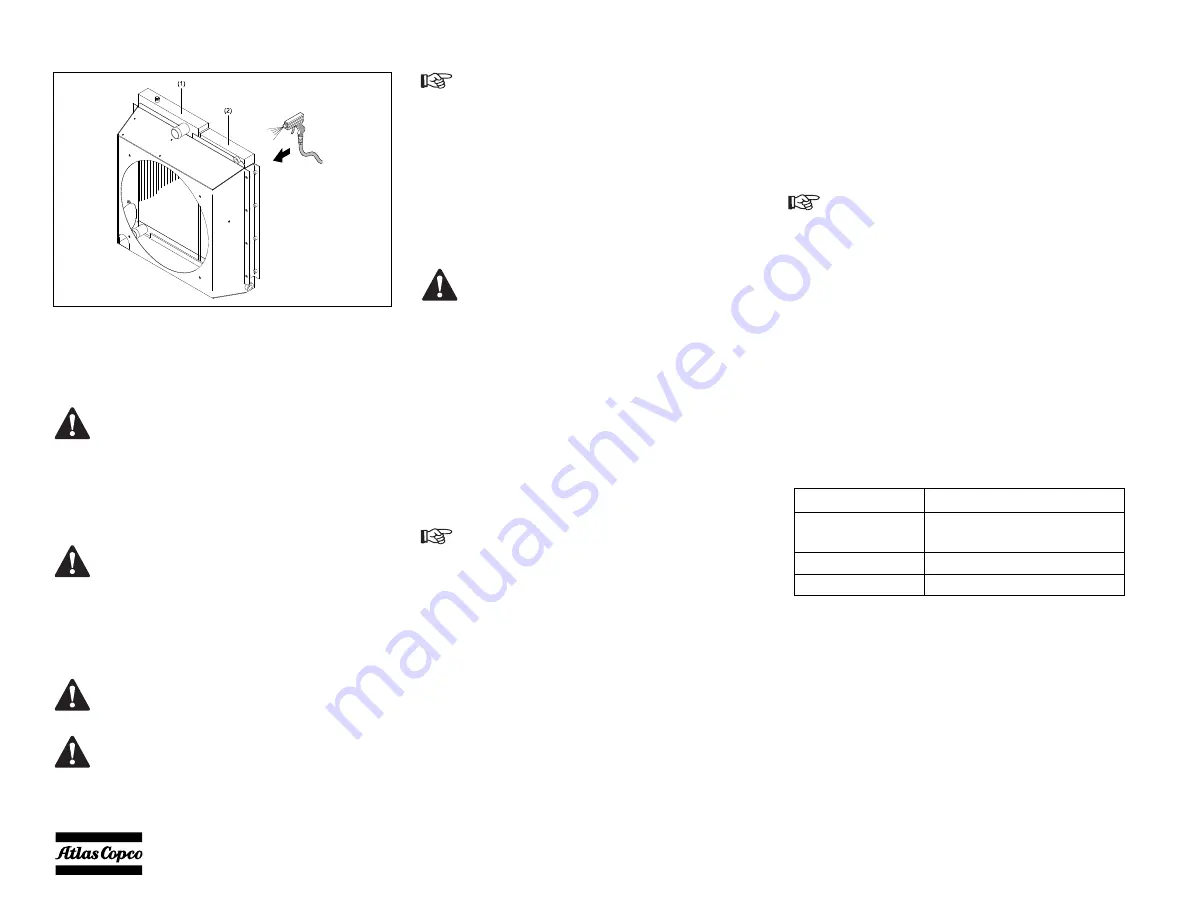

Cleaning Coolers

Keep the coolers clean to maintain the cooling efficiency.

Front cooler baffle is removable for access by unscrewing

4 bolts.

When cleaning by air jet, blow air through the cooler in

reverse direction of normal flow.

If the dirt is oily, wash the coolers with degreaser or a

cleansing agent.

A spray gun should preferably be used to apply the solvent

to the fins. Rinse the blocks by means of a water jet max.

100 psi at 2 inch distance after a soaking-in period. Steam

cleaning may also be applied.

Battery Care

An ASB (Service Bulletin) dealing elaborately with

batteries and due care is available on request.

If the battery is still dry, it must be activated as described

in point 4.7.1.

The battery must be in operation within 2 months from

being activated; if not, it needs to be recharged first.

ELECTROLYTE

Electrolyte in batteries is a sulphuric acid solution in

distilled water.

The solution must be made up before being introduced

into the battery.

RECHARGING A BATTERY

Before and after charging a battery, always check the

electrolyte level in each cell; if required, top up with

distilled water only. When charging batteries, each cell

must be open, i.e. plugs and/or cover removed.

Apply with preference the slow charging method and

adjust the charge current according to the following rule of

thumb: battery capacity in Ah (amp hours) divided by 20

gives safe charging current in Amps.

BATTERY MAINTENANCE

Keep the battery clean and dry

– Keep the electrolyte level at 10 to 15 mm above the plates

or at the indicated level; top up with distilled water only.

– Keep the terminals and clamps tight, clean, and lightly

covered petroleum jelly.

Storage

Run the compressor regularly, e.g. twice a week, until

warm.

Load and unload the compressor a few times to operate the

unloading and regulating components. Close the air outlet

valves after stopping.

Service Kits

A service kit is a collection of parts to fit a specific repair

or rebuilding task.

It guarantees that all necessary parts are replaced at the

same time which improves the uptime of the unit.

To purchase service paks contact your local Atlas Copco

representative.

Remove any dirt from the coolers with a

fiber brush. Never use a wire brush or metal

objects.

Protect the electrical and controlling

equipment, air filters etc. against

penetration of moisture

To avoid damaging the coolers, angle

between waterjet and coolers should be

approx. 90º.

Never leave spilled liquids such as fuel, oil,

water and cleansing agents in or around the

compressor.

Before handling batteries, read the relevant

safety precautions and act accordingly.

Read the safety instructions carefully

Use a commercial automatic battery

charger according to manufacturers

instructions.

If the compressor is going to be stored

without running from time to time,

protective measures must be taken as

described In a separate Service Bulletin

(ASB), which may be obtained on request.

Consult Atlas Copco.

Hours Pak

Order number

Initial 50 & 250/750

hrs

1310 9230 21

500 hrs

1310 9230 22

1000 hrs

1310 9230 23

Содержание XAS 185 KD7 IT4

Страница 1: ...XAS 185 KD7 IT4 Instruction Manual for AC Compressors English Engine Kubota V2403 M DI E3B ...

Страница 2: ......

Страница 13: ... 13 Main Parts ...

Страница 15: ... 15 Compressor regulating system Load Condition ...

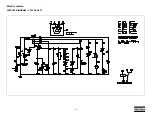

Страница 19: ... 19 Electric system CIRCUIT DIAGRAM 1310 3200 71 ...

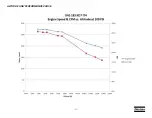

Страница 27: ... 27 ALTITUDE UNIT PERFORMANCE CURVE ...

Страница 33: ... 33 Adjustments and Servicing Procedures Adjustment of the Continuous Regulating System ...

Страница 38: ... 38 Maintenance Log Compressor Customer Serial number Service hours Maintenance action Date By initials ...

Страница 39: ... 39 Maintenance Log Compressor Customer Serial number Service hours Maintenance action Date By initials ...

Страница 40: ... 40 ...

Страница 41: ......

Страница 42: ...www atlascopco com ...