36

Maintenance and Service

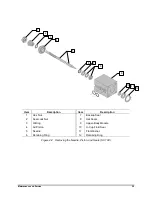

4.6.6.2 Tilt Mechanism

To install the tilt mechanism:

1. Reinstall the tilt lever onto the nozzle holder.

2. Reinstall the set screw into the tilt lever.

3. Wrench-tighten the swivel base and nozzle holder assembly onto the extension.

4. Install the bearing into the lower end of the tilt link. Secure the tilt link to the tilt lever with a

screw.

5. Slide the rotate pulley up the extension until a

1/8

-inch gap is present between the bushing

surface and the top of the rotate pulley. Check the gap by placing the module-adjusting

wrench (supplied in the service kit) in the gap. The wrench is

1/8

-inch thick and should fit

snugly in the gap.

6. Align the rotate and tilt mechanisms as shown in Figure 4-14.

7. Tighten the rotate pulley clamp screw securely. Slide the shifter bearing up and down the

extension to make sure the entire tilt mechanism moves freely and does not bind.

Item

Description

Item

Description

1

Micro-adjustment

8

Nozzle Holder

2

Upper Body Module

9

Swivel Base

3

Lower Body Module

10

Tilt Lever

4

Extension

11

Tilt Link

5

Rotate Pulley

12

Socket Cap Screw

6

Shifter Bearing

13

Unthreaded Clamp

7

Chemraz O-ring

14

Threaded Clamp

Figure 4-14 Installing the Rotate Pulley and Tilt Mechanism (SC-105)

1

2

3

4

5

6

7

8

9

10

11

12

13

14