17

of

54

TECHNICIANS' manual

ENGLISH

Core200

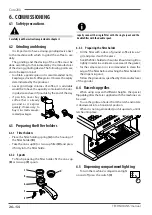

2.8.5 Pressure switch

The pressure switch makes it pos-

sible to control boiler pressure by

activating or bypassing the heating

element in the boiler. Any calibra-

tion of the pressure switch which

may be required can be carried out

with the machine in operation by

means of the screw

(24a)

located on

the body of the component.

2.8.6 Expansion valve + check valve

This is a valve consisting of an

expansion valve and a check valve.

•

Expansion valve

(34a)

: the cold

water sent from the pump to the

heat exchangers is heated. This

heating causes an increase in the

volume of water. To limit pressure

increases in the hydraulic circuit,

the valve limits the maximum

internal pressure of the circuit

to 12 Bar.

•

Check valve

(34b)

: its function is to prevent the

water from back-flowing into the exchangers in the

hydraulic circuit.

2.8.7 Electronic control unit

Its purpose is to electronically control

the coffee dose via the water flowing

through the dosing device and to check

that the heating unit is being filled with

water.

2.8.8 Volumetric dosing device

The volumetric dosing de-

vice measures the quantity of

water sent to the group in order

to dispense coffee.

The dosing device gener-

ates electrical impulses which

are sent to the electronic con-

trol unit.

These impulses are read by the control unit and

counted while the dose is being programmed.

The flashing LED light

(25a)

indicates that the electri-

cal impulse has been sent from the dosing device to the

control unit.

2.8.9 Motor pump

This is a compo-

nent that feeds the

machine, by raising

the water pressure to

0,8 - 0,9 MPa (8 - 9 bar)

in order to dispense

coffee and automa-

tically fill the heating

unit.

2.8.10 Overflow device

The cover installed

on the pressure relief

valve makes it possible

to collect any water

and steam which may

leak from the heating

unit due to a malfun-

ction and channel it

to the drain tray, via a

special hose.

2.8.11 Steam nozzle

LThe steam nozzle is connected to the top of the boi-

ler. Depending on the model, steam can be supplied by

turning the adjustment knob on the front of the machine.

2.8.12 Hot water nozzle

The hot water nozzle is connected to a suction pipe

of the boiler. Depending on the model, hot water can be

supplied in two ways:

•

Manually: by turning the adjustment knob on the

front of the machine;

•

Automatically: by selecting a button connected to a

solenoid valve.

24a

34b

34a

25a

Содержание 10003318

Страница 53: ......