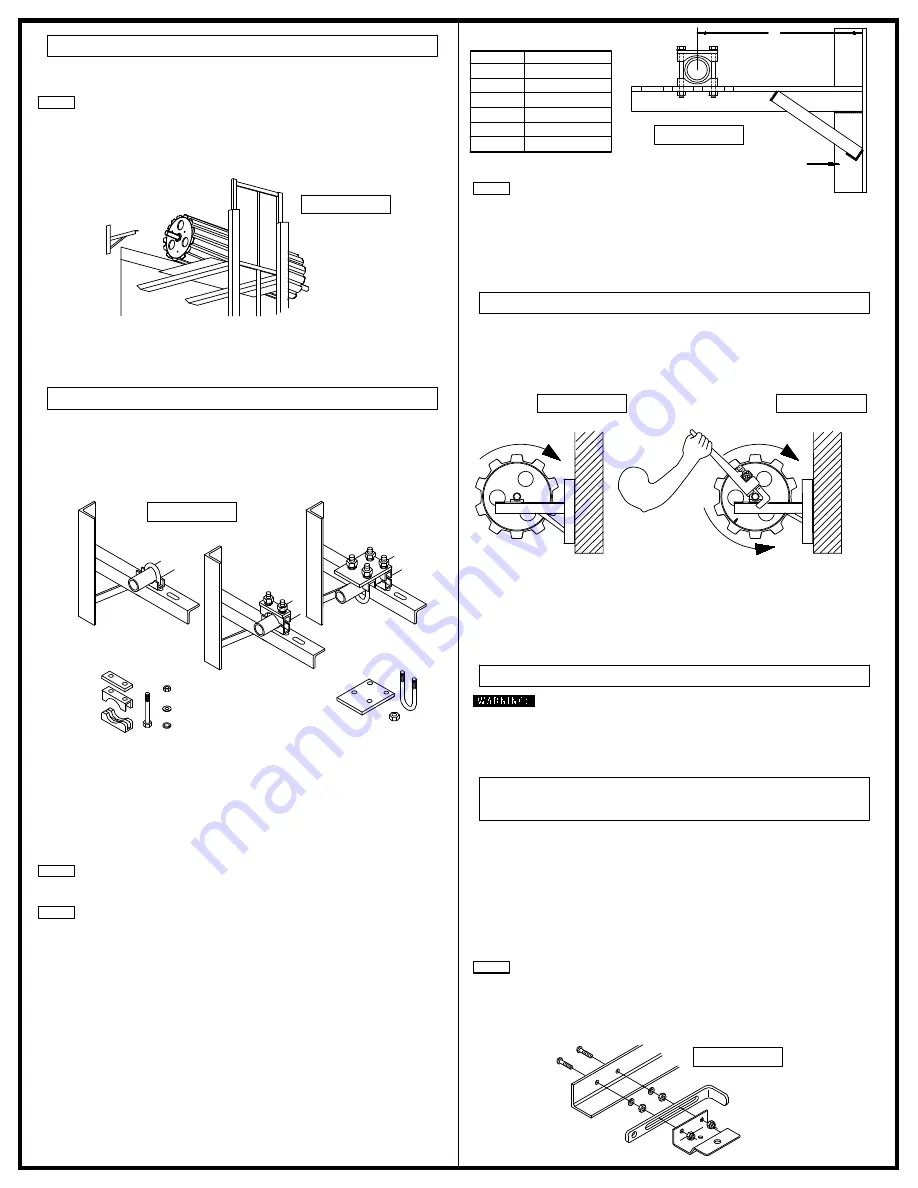

PLACE THE AXLE CLAMP (11) ONTO DOOR SUPPORT BRACKET. LIFT THE

DOOR ASSEMBLY UP ONTO THE SUPPORT BRACKET. (SEE DIAGRAM 16).

A.

NOTE:

POSITION THE DOOR AS CLOSE TO THE HEADER AS POSSIBLE. ALLOW

ROOM TO SPIN THE DOOR. DO NOT ALLOW THE DOOR CURTAIN TO

SCRAPE THE HEADER.

DO NOT USE FORKLIFTS OR GENIE LIFTS WITH UNPROTECTED

ARMS/FORKS. THIS CAN CAUSE IRREPARABLE DAMAGE TO DOOR

CURTAIN.

MANUAL PUSH-UP/ROPE DRIVE:

1.

PLACE THE AXLE CLAMP (11) ONTO HORIZONTAL MEMBER OF THE

SUPPORT BRACKET (29-36) AND UNDER THE DOOR AXLE.

2.

PLACE 3/8" U-BOLT (14) OVER DOOR AXLE AND THROUGH AXLE CLAMP.

3.

FASTEN U-BOLT USING 3/8" NUT (17), 3/8" FLAT WASHER (18) AND 3/8"

LOCK WASHER (19)---TIGHTEN SECURELY.

A.

(B)

(A)

(C)

12

11

15

16

18

19

13

14

17

DRIVE SIDE FOR REDUCTION DRIVE CHAIN HOIST AND E.O. KITS.:

1.

PLACE THE AXLE CLAMP (11) ONTO HORIZONTAL MEMBER OF THE

SUPPORT BRACKET (29-36) AND UNDER THE DOOR AXLE.

2.

PLACE AXLE CLAMP (11) AND STANDARD KEEPER PLATE (12) ON TOP

OF THE DOOR AXLE AS SHOWN.

3.

FASTEN AXLE CLAMPS AND STANDARD KEEPER PLATE TOGETHER

USING 3/8"x3-1/2" HEX BOLTS (15), 3/8" LOCK WASHERS (19), 3/8" FLAT

WASHERS (18), AND 3/8" NUTS (FINE THREAD) (16)---TIGHEN SECURELY.

B.

NOTE:

REQUIRES A MINIMUM OF 40 LBS...TORQUE TO PROPERLY SECURE

HARDWARE

FOR INSTALLATION ON NON-DRIVE SIDE FOR REDUCTION DRIVE CHAIN

HOIST AND E.O. KITS:

1.

PLACE THE AXLE CLAMP (11) ONTO HORIZONTAL MEMBER OF THE

SUPPORT BRACKET (29-36) AND UNDER THE DOOR AXLE.

2.

PLACE AXLE CLAMP (11) AND STANDARD KEEPER PLATE (13) ON TOP

OF THE DOOR AXLE AS SHOWN.

3.

FASTEN AXLE CLAMPS USING 3/8"x3-1/2" HEX BOLTS (15) 3/8"-24 NUTS

(FINE THREAD) (16), 3/8" FLAT WASHERS (18), 3/8" LOCK WASHERS (19)

AS SHOWN. TIGHTEN SECURELY.

LOCATE AXLE HARDWARE AS SHOWN FOR FINAL POSITION.

(SEE DIAGRAM 18)

C.

INSTALL CHAIN CLIP (93) APPROXIMATELY 4'-0" ABOVE FLOOR ON CHAIN

OPERATED DOORS. INSTALLATION MUST BE SECURE.

APPLY PRE-TENSION TO THE SPRINGS BY ROTATING THE DOOR TWO (2)

TURNS IN A FORWARD DIRECTION (

SEE DIAGRAM 19

). THE BOTTOM ANGLE

IS TO BE IN A 6 O'CLOCK POSITION.

A.

B.

NOTE:

WHEN INSTALLING SLIDE BOLT LOCKS THE THREADS FROM THE TRUSS

HEAD BOLTS PROTRUDING FROM THE SELF LOCKING NUT SHOULD BE

REMOVED TO A FLUSH POSITION WITH SELF LOCKING NUT TO PREVENT

DOOR FROM HANGING UP ON THE HEAD STOPS. CLAMP A PAIR OF VICE

GRIPS ON TO THE THREAD AND BREAK OFF, IF NECESSARY.

IF YOU'RE UNABLE TO ROTATE DOOR TO PRE-TENSION, USE A PIPE

WRENCH TO ROTATE AXLE IN OPPOSITE DIRECTION. WITH ONE PERSON

ON EACH SIDE OF DOOR, EACH PERSON SHOULD FIRMLY PLACE A LARGE

PIPE WRENCH ON THE DOOR AXLE (

SEE DIAGRAM 20

). PULL DOWN TO

APPLY TENSION INCREMENTALLY UNTIL YOU ACHIEVE TWO FULL

ROTATIONS OF THE DOOR AXLE. THEN TIGHTEN THE AXLE HARDWARE.

REPEAT STEP "C" IF ADJUSTMENT IS NECESSARY.

C.

D.

LESS TENSION

MORE TENSION

THE DOOR IS NOW UNDER TENSION. BEFORE CUTTING THE BANDS,

TAKE HOLD OF THE DOOR ROLL BY THE BOTTOM ANGLE.

CUT THE BANDS AND BRING THE CURTAIN DOWN NO FURTHER THAN 1/4

THE HEIGHT OF THE DOOR OPENING. SECURE CHAIN OVER THE CHAIN

RETAINER OR WEDGE A WOOD PROP BETWEEN THE BOTTOM ANGLE AND

THE DOOR ROLL TO PREVENT UPWARD TRAVEL.

A.

INSTALL THE DOOR STOPS (20) AND THE SLIDE BOLT LOCKS (21) USING

1/4"x1-1/4" TRUSS HEAD BOLT (22), 1/4" FLAT WASHER (24), 5/16" NUT (25),

AND 1/4" SELF LOCKING NUT (23) PER SIDE.

ELECTRONICALLY OPERATED DOORS STILL REQUIRE DOOR STOPS (LIFT

CLIPS) TO BE INSTALLED. SLIDE BOLT LOCKS SHOULD NOT BE INSTALLED

UNLESS ELECTRICAL INTERLOCKS ARE USED.

WINDLOCK "CERTIFIED" DOORS (203, 203IM & 204) REQUIRE SLIDE BOLT

LOCKS TO BE INSTALLED FOR PROPER WINDLOAD PROTECTION.

ELECTRICAL INTERLOCKS ARE HIGHLY RECOMMENDED.

A.

B.

C.

22

25

24

21

23

20

DIAGRAM 16

DIAGRAM 17

ROPE /

PUSH-UP

NON - DRIVE

SIDE DOOR

ABOVE 16x16

CHAIN HOIST

OR E.O.

STEP #4 - POSITION DOOR ASSEMBLY

STEP #5 - INSTALL AXLE HARDWARE

STEP #6 - PRE-TENSION SPRINGS

DIAGRAM 19

DIAGRAM 20

STEP #7 - CUT THE BANDS

STEP #8 - INSTALL DOOR STOPS

(LIFT CLIPS) AND SLIDE BOLT LOCKS

DIAGRAM 21

PAGE 3 (3-2014)

"A"

UP TO"

"A" DIMENSION

10' HIGH

9-1/4"

10"

10-1/2"

11-1/8"

12' HIGH

14' HIGH

16' HIGH

18' HIGH

20' HIGH

11-3/4"

12-1/4"

SUPPORT

BRACKET

NOTE:

1.

DIMENSIONS ARE APPROXIMATE POSITION FOR OPTIMAL PERFORMANCE.

ADJUST BY MODEL AS NEEDED.

2.

TO SPIN DOOR FOR PRETENSIONING SPRINGS, MIGHT REQUIRE MOVING

THE DOOR AWAY FROM THE WALL TO ALLOW BOTTOM BAR TO PASS. IF

SO, LOOSEN HARDWARE ONE SIDE AT A TIME & SLIDE DOOR AXLE TOWARD

WALL TO ITS BEST POSITION. BE CAREFUL DOOR WILL BE UNDER TENSION.

DIAGRAM 18

NOTE:

EXTENDED KEEPER PLATE (13) SUPPLIED FOR DOORS ABOVE 16 x 16

ONLY

D.