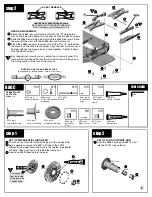

BAG C

REMOVE THESE

PARTS FOR:

Steps 4-5

TOOLS USED

step 3

ASSEMBLE THE SHORT OUTDRIVE HUB

Slide one #6573 washer onto the #6575 bolt.

Apply a generous amount of #6588 black grease to the washer

on the side facing away from the bolt head.

Place six #6574 balls into the grease against the #6575 bolt

and washer. Add the other #6573 washer. The grease will hold

the balls in place during assembly, sandwiched between the

washers. See figure for installed view.

Slide the thrust assembly into the #3912 short outdrive hub,

bearing careful not to lose any of the balls.

Insert the #6575 bolt cover.

6588

6575 bolt

6573 washer

6574

6575 cover

1:1

6909, qty 2

3/16 x 5/16 bearing

unflanged

6579, qty 4

diff drive ring

3976, qty 4

3/8 x 5/8 bearing

rubber sealed, unflanged

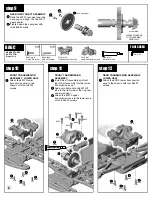

step 4

ASSEMBLE THE LONG OUTDRIVE HUB

Insert one #6909 bearing into the #3912 long hub.

Add a light coat of #6591

Assoc.

lube to the long hub

face where shown.

Place a #6579 diff drive ring and then the gear assembly

on the hub.

ASSEMBLE THE HUBS

Add a light coat of #6591

Assoc.

lube to the #3912 short hub face where shown.

Place a #6579 diff drive ring on the hub.

Push the #3912 short hub into the back side of the

differential ring gear. Center the diff bolt in the hub.

CHECK ALIGNMENT OF HUBS

Tighten the diff with your 5/64" Allen wrench, but not completely.

Rotate the diff hubs several times as you are tightening the bolt to check proper

alignment of the parts.

Read step 9 carefully.

7

8

6909

3912 long

6591

6579

6591

6579

3912 short

step 5

FINAL OUTDRIVE ASSEMBLY

Press the #3926 outdrive dust cap into

the #3912 long outdrive.

Place one #3911 outdrive shim on both

the long and short hubs.

Place one #3976 bearing over each

outdrive hub.

3912 long

3912 short

3911

3911

1:1

6

3911, qty 4

outdrive shim

1:1

1:1

9

5/64

6573 washer

3912 short

1:1

3976, qty 4

3/8 x 5/8 bearing

rubber sealed, unflanged

3976

3976

back side

front side

3926, qty 2

long outdrive

dust cap

3926 dust cap

ADJUST THE DIFF

As you tighten the diff bolt, you will notice the T-nut ears moving closer to the bottom of the diff hub slot. This compresses the spring

behind the T-nut. The spring should be fully compressed at the same time the T-nut reaches the end of the slot.

Caution:

Pay close

attention to feeling when the spring is full compressed.

Do not overtighten the bolt.

When you feel the spring fully compressed, loosen the diff bolt 1/8 to 1/4 of a turn. No more, no less. Your diff should now operate very

smoothly when turning the hubs in opposite directions. After you have driven the car once, recheck the diff adjustment. Never adjust

the diff any other way.

Now assemble the second diff the same way.

10

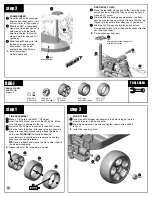

IMPORTANT NOTE: STEPS 5, 6, 7 AND 8 INVOLVE SETTING THE MESH OF THE BEVEL GEARS.

Be sure to use only one

shim on each side of the

differential