29

The warranty on Corbin Russwin products becomes void if the product is modified in any way, regardless of whether the modifications causes or contributes to any alleged defect. If a

Corbin Russwin product is modified it may no longer meet industry certification and quality control standards applicable to the original product and is no longer a genuine Corbin Russwin product.

Copyright © 1999-2018, ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved. Reproduction in whole or in part without the express written permission of ASSA ABLOY Access

and Egress Hardware Group, Inc. is prohibited. Patent pending and/or patent www.assaabloydss.com/patents.

Routine Maintenance

UT5200 Parts Manual

Periodic adjustment and maintenance will substantially lengthen the life of the lockset and ensure the best

possible trouble-free operation.

Time frames in the following maintenance items are based on normal frequency of operation. For high traffic

or high abuse applications, perform suggested maintenance more frequently.

If you have questions regarding installation or adjustment, contact an authorized Corbin Russwin distributor

or local sales representative.

LUBRICATE CYLINDER

Lubricate (conventional) cylinder with small amount of KeyLube by Medeco

®

every six months. Petroleum

based liquid spray lubricants such as KeyLube by Medeco

®

should never be mixed with dry lubricants.

LUBRICATE MOVING PARTS

Lubricate moving parts of inside and outside chassis with a small amount of grease or other petroleum

lubricant every two years.

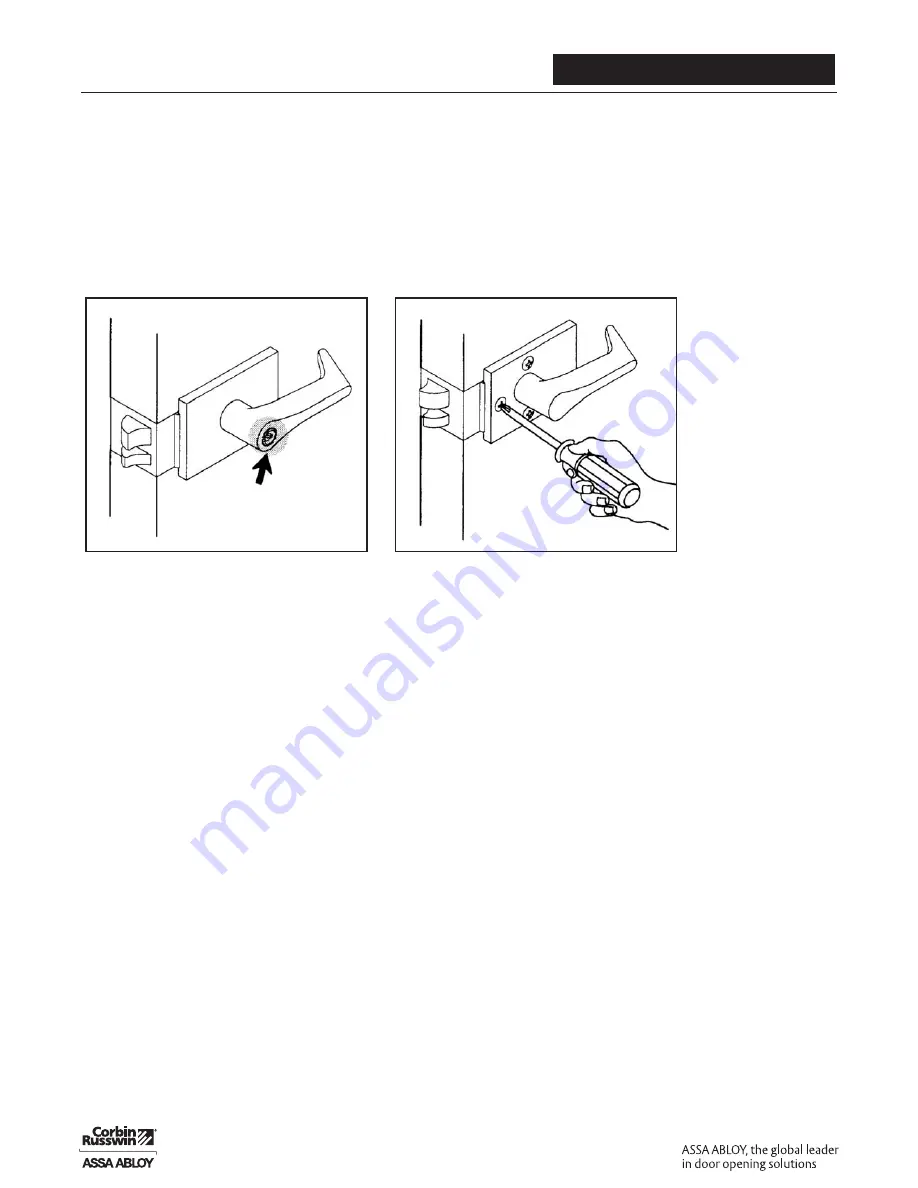

TIGHTEN SCREWS

Check lockset for secure fastening to door once a year. Tighten throughbolts as needed.

CARE FOR LEVERSET FINISH

Clean leverset using only a soft, damp cloth. Using lacquer thinners, caustic soaps, abrasive cleaners

or polishes could damage the coating, resulting in tarnishing.

5

5

5

5

Lubricate Here

Tighten

Screws