17.

Problem:

Console does not light when turned on:

Console lights when turned on, but

handpiece does not turn:

Improper display:

Motor slowing down or sluggish:

Handpiece motor light does not turn on:

Vacuum doesn’t turn off when hoses are

in their holders:

Pressure fails to stabilize:

Pressure fails to turn off at approx. 50 PSI:

Unit fails to build pressure:

Red LED on the plumbing chassis is lit:

Compressor is on, but gauge shows no

increase in pressure:

HVE vacuum switch (yellow dot) is in the

On position, but vacuum doesn’t activate

when hose is removed:

HVE vacuum pressure seems lower:

Saliva ejector switch (red dot) is in the

On position, but vacuum doesn’t activate

when hose is removed:

Correction:

Check console to power connection.

Check that voltage is proper voltage.

Check fuse. If blown, replace with 6.3A/250V slo-blo fuse for

120V operation, & 3.15A/250V slo-blo fuse for 230V operation.

Check secondary fuses. If blown, replace with 0.63A/250V

slo-blo fuses.

Check motor plug connection.

Check foot switch connection.

Depress foot switch.

Increase RPM.

Check that an instrument is properly seated in the handpiece

and the collet is closed.

Turn power switch off, wait 5 seconds, then turn back on to reset.

Change ratio setting to match handpiece.

Dirty, under-lubricated handpiece.

Handpiece lubricant is running into motor.

After lubricating, set handpiece with head down to let excess

lubricant drain out.

Check bulb. Note: Do Not Handle Bulb With Fingers.

Ensure that HVE and Low Volume (Saliva Ejector) vacuum

heads are firmly placed in their holders.

Check spring-loaded lever in holders.

Check that air and water bottles are tight. Check line and fittings

for air leaks.

Check for broken cable to pressure switch.

Check that bottles are tight. Check wires for breaks to solenoid

switch.

Empty full waste container.

Check waste level connections.

Check that float in waste container moves freely.

Check three-way valve to see if the valve is switched. If the

valve failed to switch, the air will continue to come out of the

filter. Check the line from the compressor to the valve for a

rupture. Check the electrical connections to the three-way valve.

Inspect the toggle lever on the vacuum holder to see if it is

stuck. Loosen the setscrew under the switch and adjust the

switch for proper operation. Check the electrical connections on

the switch. Check the relay.

Check to see if the container is tight. Check the trap to see if it is

clogged. Check to see if line to motor is crimped.

Inspect the toggle lever on the vacuum holder to see if it is

stuck. Loosen the setscrew under the switch and adjust the

switch for proper operation. Check the toggling connections to

the air pilot valve and pump. Check to see if the air pilot valve is

functioning by removing the line to the pump and seeing if air is

present.

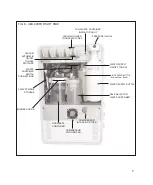

TROUBLESHOOTING: