E

2007

CCN 15250384

&

(800) 276-4658

D

FAX (800) 266-7016

INGERSOLL RAND COMPANY

LTD

P.O. BOX 151

D

ONE ARO CENTER

D

BRYAN, OHIO 43506-0151

OPERATOR’S MANUAL

PD05X-X-X-B

RELEASED: 11-10-05

REVISED:

2-28-07

(REV. 03)

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

1/2” DIAPHRAGM PUMP

1:1 RATIO, METALLIC

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Refer to Model Description Chart to match the pump material options.

637427-XX for fluid section repair (see page 4).

637428 for air section repair (see pages 6 and 8).

PUMP DATA

Models

see Model Description Chart for -XXX".

. . . . . . . . . . . .

Pump Type

Air Operated Double Diaphragm.

. . . . . . . . .

Material

see Model Description Chart.

. . . . . . . . . . . .

Weight

PD05A-XAS-XXX-B

10.36 lbs (4.70 kgs)

. . .

. . . . .

PD05A-XSS-XXX-B

16.57 lbs (7.52 kgs)

. . . . .

PD05R-XAS-XXX-B

8.04 lbs (3.65 kgs)

. . . . .

PD05R-XSS-XXX-B

14.25 lbs (6.46 kgs)

. . . . .

Maximum Air Inlet Pressure

100 p.s.i.g. (6.9 bar)

. . . . . . . . .

Maximum Material Inlet Pressure

10 p.s.i.g. (0.69 bar)

. . . . .

Maximum Outlet Pressure

100 p.s.i.g. (6.9 bar)

. . . . . . . . . .

Air Consumption

@ 40 p.s.i.

1 c.f.m. / gallon (approx.)

. . . . . . . . .

Maximum Flow Rate

(flooded inlet)

12.0 g.p.m. (45.4 l.p.m.)

. . . . .

Displacement / Cycle @ 100 p.s.i.

0.039 gallons (0.15 lit.)

. . . .

Maximum Particle Size

3/32" dia. (2.4 mm)

. . . . . . . . . . . .

Maximum Temperature Limits (diaphragm / ball / seat material)

E.P.R. / EPDM

-60

_

to 280

_

F (-51 to 138

_

C)

. . . . . . . . . . .

Hytrel

R

-20

_

to 150

_

F (-29

_

to 66

_

C)

. . . . . . . . . . . . . . . .

Nitrile

10

_

to 180

_

F (-12 to 82

_

C)

. . . . . . . . . . . . . . . . .

Polypropylene

35

_

to 150

_

F (2

_

to 66

_

C)

. . . . . . . . . . .

Polyurethane

10

_

to 150

_

F (-12

_

to 66

_

C)

. . . . . . . . . . . .

Santoprene

R

-40

_

to 225

_

F (-40

_

to 107

_

C)

. . . . . . . . . . .

Teflon

R

PTFE

40

_

to 225

_

F (4

_

to 107

_

C)

. . . . . . . . . . .

Viton

R

-40

_

to 350

_

F (-40

_

to 177

_

C)

. . . . . . . . . . . . . . . .

Dimensional Data

see pages 11 and 12

. . . . . . . . . . . . . . . .

Noise Level

@ 70 p.s.i., 60 c.p.m.

75.0 db(A)

À

. . . . .

À

The pump sound pressure levels published here have been updated to an Equivalent

Continuous Sound Level (L

Aeq

) to meet the intent of ANSI S1.13-1971, CAGI-PNEU-

ROP S5.1 using four microphone locations.

NOTICE: All possible options are shown in the chart however certain com-

binations may not be recommended, consult a representative or the fac-

tory if you have questions concerning availability

.

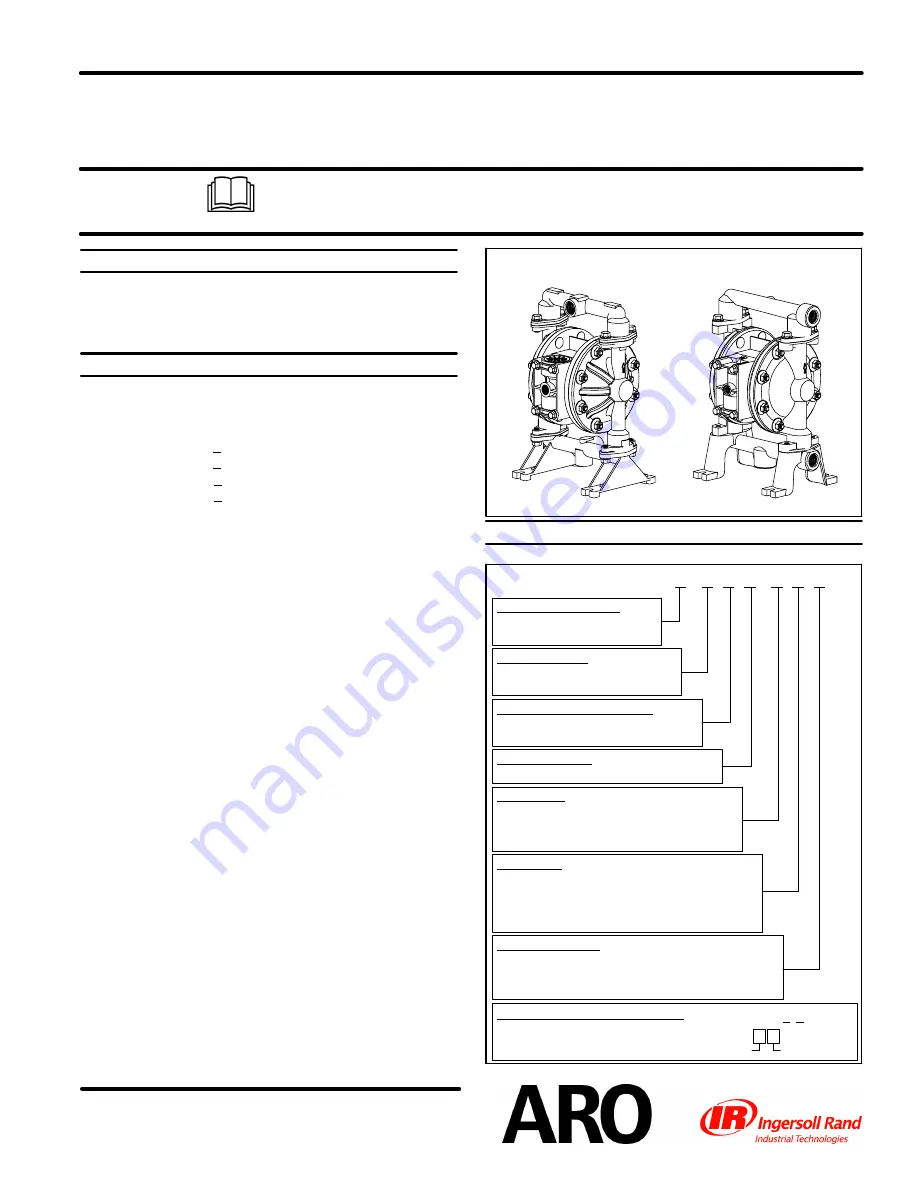

Figure 1

PD05R-XSS-XXX-B

PD05A-XAS-XXX-B

MODEL DESCRIPTION CHART

PD05 X - X X S - X X X - B

PD05A - AAS - S X X - B

637427 - X X

Diaphragm

Ball

FLUID SECTION SERVICE KIT SELECTION

EXAMPLE: Model # PD05A-AAS-SAA-B

Fluid Section Service Kit # 637427-AA

Seat Material

F - Aluminum

P - Polypropylene

S - Stainless Steel

Diaphragm Material

A - Santoprene

T - Teflon PTFE / Santoprene

C - Hytrel

U - Polyurethane

G - Nitrile

V - Viton

Ball Material

A - Santoprene

T - Teflon PTFE

C - Hytrel

U - Polyurethane

G - Nitrile

V - Viton

S - Stainless Steel

Hardware Material

S - Stainless Steel

Fluid Caps / Manifold Material

A - Aluminum

S - Stainless Steel

Fluid Connection

A - 1/2 - 14 N.P.T.F. - 1

B - Rp 1/2 (1/2 - 14 BSP)

Center Section Material

A - Aluminum

R - Polypropylene