4

Installing Connector Blocks and Steam

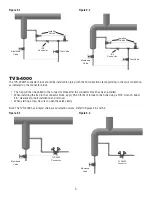

Traps on Connector blocks

Standard

The Standard connector block should be installed in piping with the flow direction stamp pointing in the correct direction as

indicated on the connector block.

• The trap will then be bolted to the connector block after the connector block has been installed.

• When installing the trap to the connector block, apply 35-50 ft-lbs of torque to the bolts using a 9/16” wrench. Allow

2.5” clearance for bolt installation and removal.

• When starting a trap, be sure to open the valve slowly.

Note: Armstrong strongly recommends adding an upstream strainer and isolation valves upstream and downstream of the

trap. Refer to figures 4.1 and 4.2.

IS2

The IS2 connector block should be installed in piping with the flow direction stamp pointing in the correct direction as

indicated on the connector block.

• The trap will then be bolted to the connector block after the connector block has been installed.

• When installing the trap to the connector block, apply 35-50 ft-lbs of torque to the bolts using a 9/16” wrench. Allow

2.5” clearance for bolt installation and removal.

• When starting a trap, be sure to open the valve slowly.

Note: Armstrong strongly recommends isolation valves upstream and downstream of the trap. Refer to figures 5.1 and 5.1.

Isolation

Valves

Strainers

Test Valve

Standard

Connector

Blowdown

Valve

Isolation

Valves

Strainer

Standard

Connector

Test Valve

Blowdown

Valve

Figure 4.1

Figure 4.2