Page 6

# 44876D006

SETUP PROCEDURE

PSC Motor

For proper cooling operation, the airflow through the

indoor coil should be between 350 and 450 CFM per ton

(12,000 Btuh) of cooling capacity based on the rating of

the outdoor unit.

The cooling blower speed is factory configured to provide

correct airflow for an outdoor unit that matches the

maximum cooling capacity rating of the electric furnace. If

the outdoor unit is smaller than the maximum cooling

capacity rating for the electric furnace, the cooling blower

speed may need to be changed (see Table 2).

IMPORTANT: The cooling blower speed must be set to

provide a minimum of 350 CFM airflow per ton (12,000

Btuh) of outdoor cooling capacity.

Changing Blower Speed

1.

Disconnect all power supplies.

2.

Remove the electric furnace access panel.

3.

Locate pin number 2 on the blower relay. Two black wires

are connected to this terminal pin. One connects to pin

number 5 on the blower relay and the other connects to

an inline splice connected to a red or black wire.

4.

Remove the wire going to the 4-pin blower motor

connector from the splice.

5.

Connect the blower lead (Red - LO, Black - HI) to the

splice from the 4-pin blower motor connector.

Unused blower speeds are shipped from the

factory covered with a plastic cap. Remove the

cap from the new blower speed terminal and place

it over the factory-set blower terminal.

6.

Replace electric furnace access panel.

7.

Reconnect power.

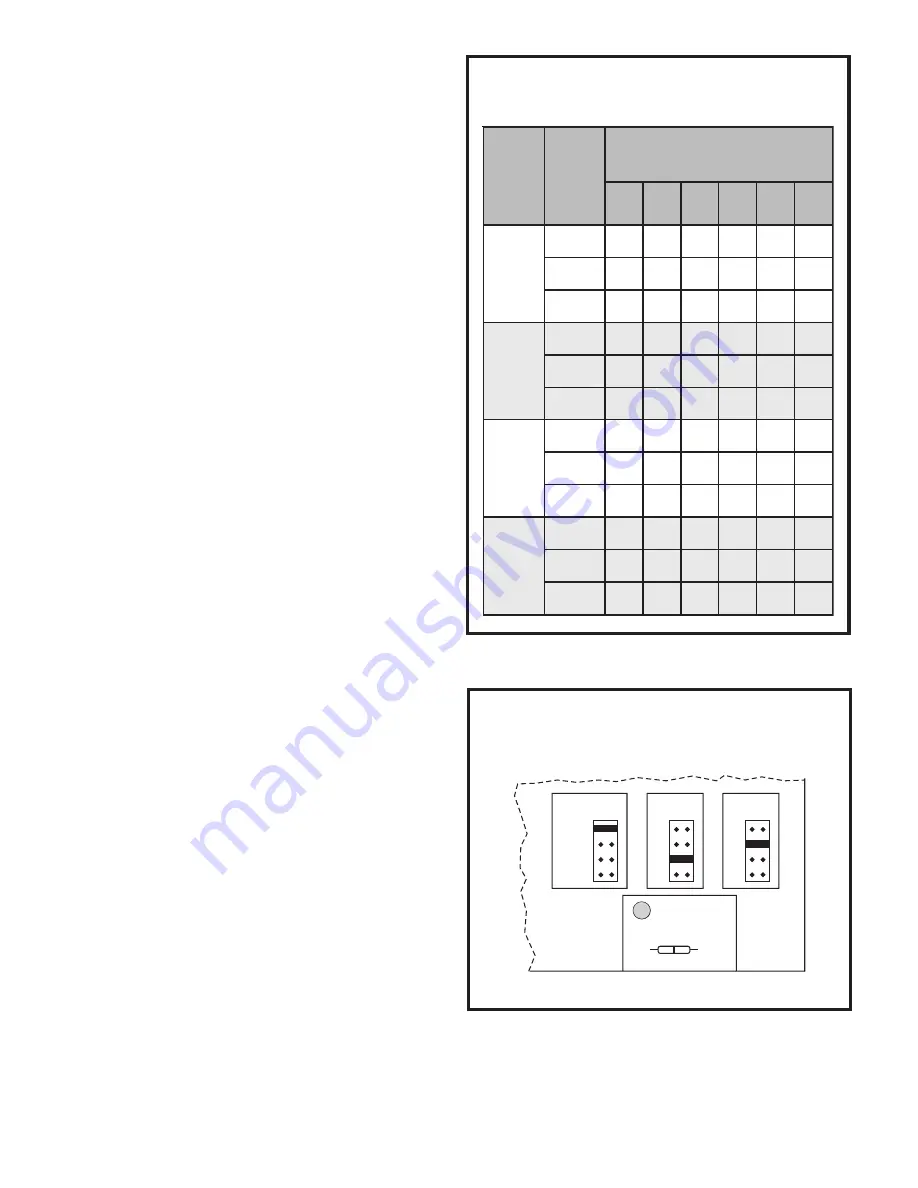

Variable Speed Motor

Locate the motor control board in the blower control box.

Set the HEAT and COOL CFM taps by moving the board

jumpers to the A, B, C, or D positions (see Figure 2)

based on the information found in the

Application Table

on page 11. The ADJUST tap on the control board can be

used to raise or lower the table CFM’s. The (+) tap will

raise the table CFM by 10%, and the (–) tap will lower the

table CFM by 12%.

IMPORTANT: When changing the

control taps, the high voltage must be off in order for

the new settings to take effect.

l

e

d

o

M

r

e

w

o

l

B

d

e

e

p

S

c

i

t

a

t

S

l

a

n

r

e

t

x

E

@

M

F

C

.

C

.

W

.

n

i

e

r

u

s

s

e

r

P

1

.

0

2

.

0

3

.

0

4

.

0

5

.

0

6

.

0

8

0

C

F

E

w

o

L

3

8

5

3

6

5

7

5

5

1

4

5

2

2

5

3

7

4

m

u

i

d

e

M

2

6

8

5

5

8

4

3

8

4

9

7

8

4

7

7

7

6

h

g

i

H

9

5

1

1

6

9

0

1

9

2

0

1

7

5

9

1

7

8

4

9

7

2

1

C

F

E

w

o

L

8

3

8

7

2

8

8

0

8

8

7

7

6

4

7

9

9

6

m

u

i

d

e

M

5

6

2

1

5

5

2

1

5

3

2

1

5

1

2

1

3

7

1

1

8

1

1

1

h

g

i

H

8

5

3

1

0

4

3

1

1

1

3

1

2

8

2

1

1

3

2

1

9

7

1

1

6

1

C

F

E

w

o

L

1

6

1

1

3

5

1

1

8

3

1

1

5

1

1

1

1

9

0

1

0

5

0

1

m

u

i

d

e

M

9

6

5

1

1

4

5

1

7

0

5

1

0

6

4

1

5

0

4

1

1

4

3

1

h

g

i

H

9

6

7

1

5

3

7

1

3

0

7

1

6

2

6

1

0

7

5

1

9

8

4

1

0

2

C

F

E

w

o

L

2

3

6

1

6

6

5

1

1

8

5

1

4

4

5

1

2

8

4

1

7

1

4

1

m

u

i

d

e

M

3

6

1

2

3

0

1

2

8

5

0

2

0

0

0

2

7

4

9

1

5

5

8

1

h

g

i

H

8

9

3

2

4

9

3

2

6

6

2

2

0

8

1

2

9

0

1

2

2

4

0

2

Blower Performance Chart

PSC Motor

Table 2

This model is designed for use with heat pumps as

well as air conditioning systems. The motor control

board needs to sense a signal on the “O” thermostat

wire in order to use cooling delay timing. For a

DEHUMIDIFY

CUT TO ENABLE

COOL

HEAT

ADJUST

NORM

A

B

C

D

A

B

C

D

(+)

(–)

TEST

D1

Motor Board Taps and

Dehumidify Resistor

Figure 2