3

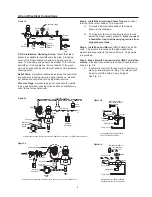

Step 4. Install the Armstrong Steam Trap

and connect

the trap to the return header. It is important:

A. To provide a dirt pocket ahead of the trap as

shown in the drawings.

B. To make sure the return header pressure is well

below the steam supply pressure.

Never connect

a humidifi er trap to a line carrying returns from

high pressure traps.

Step 5. Install Fan and Motor

of AMAF, AMEF, and FSA

units. The bracket is located on the side opposite the

steam discharge outlet in the humidi

fi

er cap. Cap screws

are provided.

Step 6. Make Electric Connections for AMEF model fan

motors.

Electrical connections are shown in double dash

lines in Fig. 3-2.

A. If automatic control of the fan motor is desired, in-

stall a pneumatic-electric relay. The relay should

be set to start fan with a 2 psi air signal.

See Fig. 3-2.

P.R.V. Installation. Reducing Valves.

Where the steam

pressure available for humidi

fi

ers is too high, a reducing

valve of the single-seated or dead-end type should be

used. The reducing valve should be at least 10 ft. from the

humidi

fi

er. If the supply line is more than 20 ft. long, pro-

vide a drip pocket and extra trap just ahead of the pressure

reducing valve.

Relief Valve.

A pressure relief valve between the humidi

fi

er

and pressure reducing valve is a good insurance. Humidi-

fi

er bodies are only rated for 60 psig steam service.

Pressure Gage.

A pressure gage or connection for install-

ing a gage between reducing valve and the humidi

fi

er may

save its cost many times over.

Air and Electrical Connections

10' Min.

Strainer

Steam

Trap

Steam

Trap

Steam

Supply

Dirt

PRV

Relief

Valve

Pressure Gage

To Low

Pressure

Return

Check

Valve

Figure 3-1.

Motor

Compressed air hookup. Electrical connections for AMEF units are shown. For AMAF model omit electric.

Compressed air hookup showing air powered fan and air line accessories for AMAF units.

Wiring diagram for standard 120V or

240V FSA or VSA Humidifiers.

Wiring diagram for 120V or 240V VSA

Humidifier with 24V line to humidistat.

Steam In

Steam Trap

Steam

Trap

Pneumatic

Temperature

Switch

Pneumatic

Temperature Switch

Air Supply

Oiler

Air Fan Assembly

Steam In

Humidity

Controller

Filter

Steam

Out

120 V 240 V Line In

P.E. Switch

Humidity

Controller

Hand

Switch

Armstrong A-8581-A

(HC-101) Humidity

Controller

Armstrong A-8581-A

(HC-101) Humidity

Controller 24 V

Power Source

Power Source

Solenoid Coil

Solenoid Coil

Temp. Switch

Temp. Switch

Switch

Fan

(when used)

Junction

Box

Junction

Box

Relay

Air

In

Switch

Fan

(when used)

Figure 3-4.

Figure 3-3.

Figure 3-5.

Figure 3-2.