34

2. Check track alignment and continue

adjustment until proper alignment is

obtained.

NOTE: Make sure correct track

tension is maintained after adjust-

ing track alignment.

3. After proper track alignment is

obtained, tighten the idler wheel

axle cap screw to 34 ft-lb; then

tighten the adjusting bolts securely

against the axle.

4. Field test the track under actual con-

ditions.

5. After the field test, check the align-

ment of the track. If additional adjust-

ment is necessary, repeat Adjusting

Track Alignment procedure.

Suspension

The suspension should be adjusted for

the operational needs and riding prefer-

ence of the operator.

The front shock springs determine the

amount of ski pressure and the reaction

of the front suspension to rough terrain.

The amount of ski pressure can also be

changed by adjusting the length of the

skid frame front arm limiter straps.

On the rear arm float shock, this adjust-

ment is achieved by increasingly or

decreasing the air pressure in the rear arm

air shock absorber.

Adjusting Fox Air Shocks

NOTE: It is recommended to moni-

tor the air pressure in the air shocks

once every month.

NOTE: Adjusting air shocks may

be done by the snowmobile owner if

qualified to do so. If the owner does

not feel qualified, take the snowmo-

bile to an authorized Arctic Cat

Snowmobile dealer for this service.

This service is at the discretion and

expense of the snowmobile owner.

The air shocks are individually adjustable

for the terrain conditions and driving style

of the operator. The shocks are preset at the

factory (see chart) as an initial setting;

however, it is possible to “fine tune” the

shocks to match the operator’s weight, rid-

ing style, and terrain conditions.

NOTE: Adding air pressure will

increase the air spring force; reduc-

ing air pressure will decrease air

spring force.

Checking and adjusting air pressure must

be done at riding temperature (outside).

Also, it is advisable to check air pressure

when the outside temperature varies

more than 25°.

NOTE: Care should be taken to have

equal pressure in the front (ski) shocks

before operating the snowmobile.

To increase or decrease air pressure, use

the following procedure.

NOTE: When adjusting air pres-

sure, all weight must be removed

from the suspension, and the shock

absorbers must be fully extended.

1. Remove the air valve cap from the

shock.

2. Thread the valve of Shock Absorber

Air Pump onto the shock air valve

approximately six rotations.

NOTE: As the pump is being

attached to the shock, the hose will

fill with air. This will result in a lower

gauge pressure 2-5 psi.

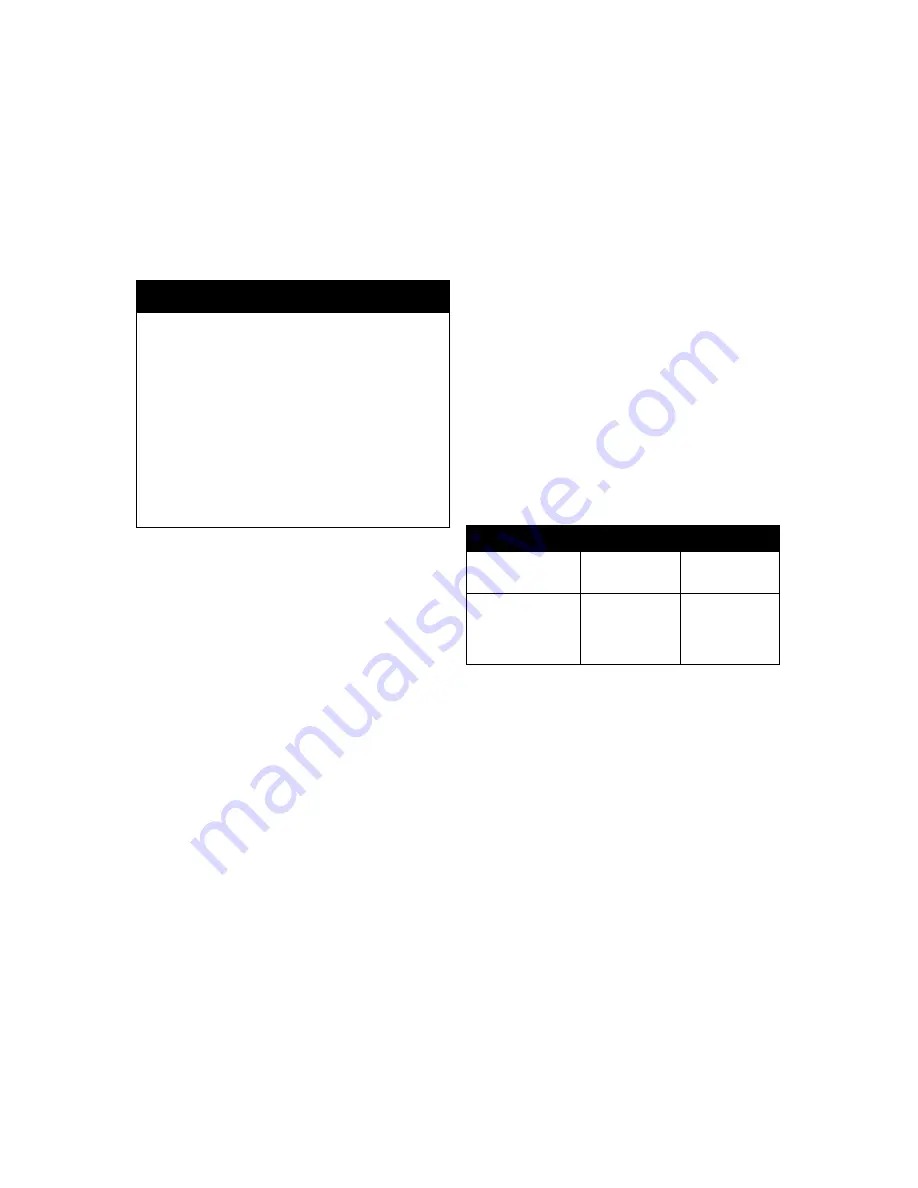

! WARNING

Always make sure the adjusting bolts

are snug against the axle and the

idler wheel cap screws are tightened

to specifications. Failure to do so

could cause the track to become

extremely loose and, under some

operating conditions, allow the idler

wheels to climb over the track lugs

forcing the track against the tunnel

causing the track to “lock.” If a track

“locks” during operation, severe per-

sonal injury could result.

Initial Setting Chart

Front Shock

(Ski)

Front Arm

Shock

Rear Arm

Shock

90 psi (Main

Chamber)

150 psi (Evol

Chamber)

50 psi (Main

Chamber)

125 psi (Evol

Chamber)

150 psi (Main

Chamber)

250 psi (Evol

Chamber)