2

AIR FEED

Use only compressed air. Check airline for damage from humidity &

contaminants. In order to protect the tool from premature wear, we

recommend the use of an in line moisture filter and air regulator.

Air inlet thread connection size on the tool is

¼

” NPT.

WARNING:

Do not use air supply greater than recommended

85-95 PSI

or tool may be damaged or burst.

1. Connect air supply then switch ON/OFF valve

to ON position

2. To turn on and adjust vacuum system rotate silver

knob on side of tool and turn it clockwise until

desired amount of vacuum is obtained to hold rivet

in place and eject spent mandrel into the collection

cup. If you don't want to use the vacuum system

rotate the silver knob counter-clockwise to shut it

off. The tool will still function but must be tilted

backwards to allow spent mandrel to fail into

collection cup.

ADDITION OF HYDRAULIC FLUID

1. Disconnect air supply to tool and switch ON/OFF valve to

OFF position.

2. Remove seal screw and seal (see Fig. 3)

3. Screw the priming pump of filled oil into the bleed screw

hole. Actuate the priming pump by pressing down and

releasing several times until resistance is felt. (Fig. 4)

4. Remove the priming pump and the excessive oil will flow

out. Wipe away and clean out the excessive oil and replace

the seal and screw.

IMPORTANT: Use only Anti-Foam Hydraulic Fluid

WARNING:

ALWAYS WEAR SAFETY GLASSES

WHEN OPERATING AND PERFORMING MAINTENANCE ON TOOL

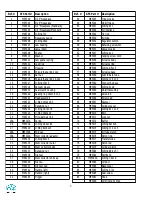

Содержание MARSON MP-4V

Страница 4: ...4 MP 4V BREAKDOWN PARTS LSIT ...