Use and maintenance handbook

Page 21

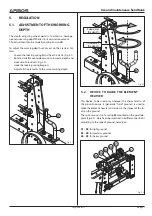

5. REGULATION

5.1. ADJUSTMENT

OF

THE

WORKING

DEPTH

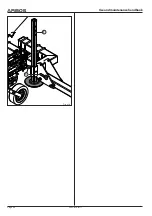

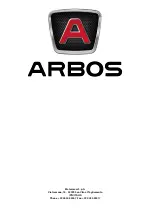

The depth adjusting wheel permits to obtain a homoge-

neous processing depth thanks to its vertical movement.

This adjustment can be made by acting on crank

B

.

To adjust the working depth simply act on the crank as fol-

lows:

•

Loosen the locking spring

A

and free the crank (Fig.5.1).

• Rotate

crank

B

counterclockwise to increase depth and

clockwise to reduce it (Fig.5.2).

•

Hook the locking spring

A

again;

•

Adjust all the elements to the same working depth.

A

B

Fig. 5.1

It decreases

the depth

It increases

the depth

B

Fig. 5.2

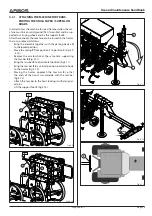

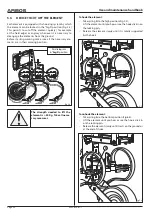

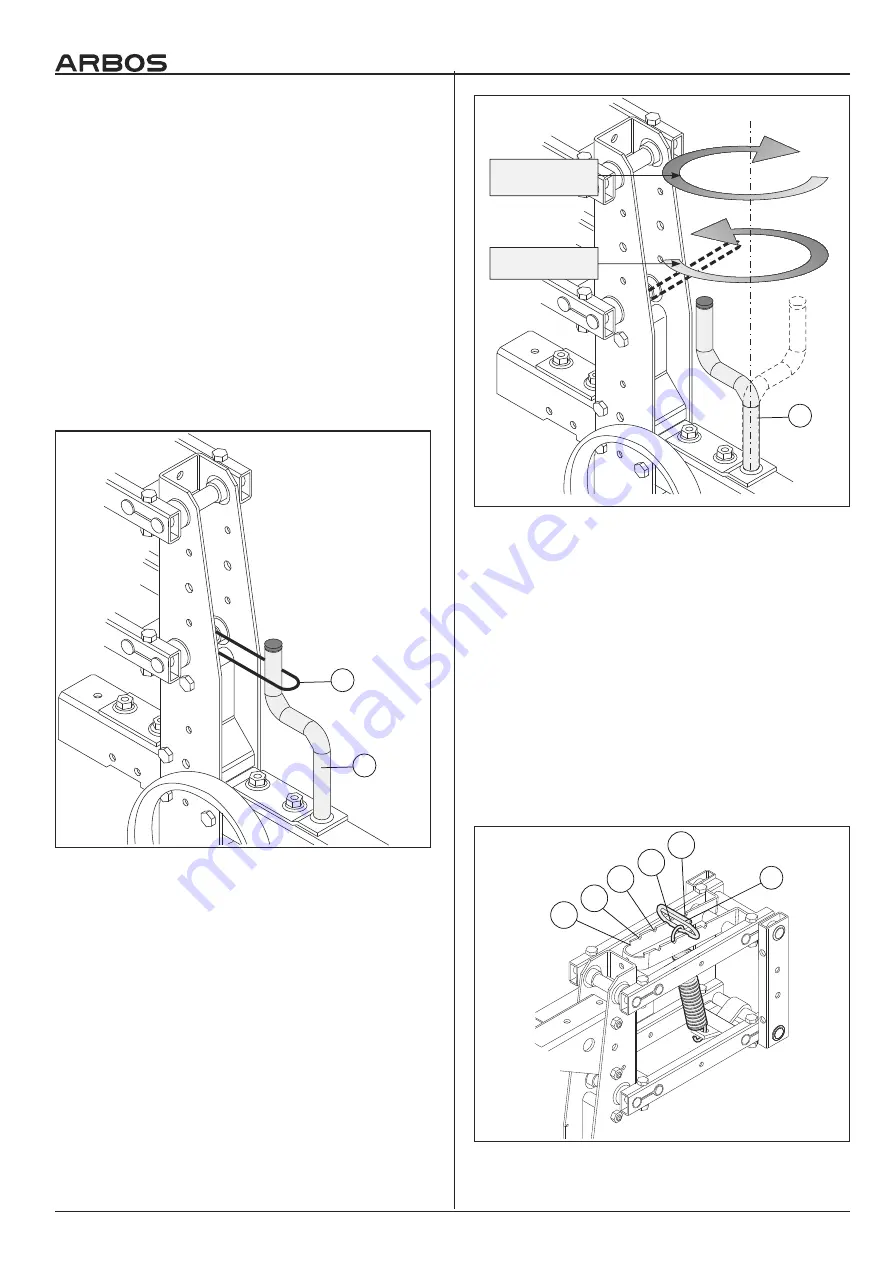

5.2. DEVICE TO MAKE THE ELEMENT

HEAVIER

This device, to be used only wherever the characteristics of

the ground require it (generally “hard” ground), is used to

make the element heavier and increase the impact of the to-

ols on the ground.

The system consists of a spring

M

mounted on the parallelo-

gram (Fig.5.3) , which can be switched in 3 different positions

according to the type of ground, namely on:

K1 - K2

for light ground;

K3 - K4

for medium ground;

K4 - K5

for heavy ground;

C

K1

K2

K3

K4

K5

Fig. 5.3

Содержание Unica Super

Страница 2: ......

Страница 4: ...www matermacc it Use and maintenance handbook...

Страница 16: ...www matermacc it Use and maintenance handbook Page 12...

Страница 24: ...www matermacc it Use and maintenance handbook Page 20 F 5 Fig 4 14...

Страница 34: ...www matermacc it Use and maintenance handbook Page 30...

Страница 36: ......

Страница 37: ...Use and maintenance handbook...

Страница 38: ...Matermacc S p A Via Gemona 18 33078 San Vito al Tagliamento PN ITALIA Phone 39 0434 85267 Fax 39 0434 85517...