User Manual Thermal X - R Series Chillers

Page 26

C1

F

L

T

F

a

ult

Safety switch

open

Check operation of safety switches (circuit that connects to input 2) Check Hp,

LP, water level switches are made. Fan/pump and compressor overloads are

made.

Work Around

Bridge out components one after the other and test to see when unit doesn’t trip.

H

P

F

a

ult

Faulty Fans

Check operation of condenser fans. Replace if faulty.

Condenser coil

dirty

Check condition of condenser is clean and air moves through freely over coil.

Ambient

Temperature to

High

Ambient temp to high. Condensing temp to be brought down. (Spray coils with

water)

Faulty

transducer

Check operation of transducer/ reading correctly

LP

F

a

ult

Low refrigerant

charge

Check refrigerant system operation, check super heat and sub cooling are with in

normal operating ranges

Faulty Tx Valve

Check operation of Tx valve (opening and closing as required)

Low water flow

Check water flow through plate pack heat exchanger is sufficient

Water fouling

Check buffer tank and coil water is clean and coil not coated in mud/debris

Faulty

transducer

Check operation of transducer/reading correctly

Hi

gh

Ret

urn

Wa

ter

T

emp

Faulty Probe

Check probe operation/Re-calibrate sensor, replace probe

Low refrigerant

charge

Check refrigerant system operation, check super heat and sub cooling are with in

normal operating ranges

H

ig

h

Su

pp

ly

Wa

ter

T

emp

Faulty probe

Check operation of transducer/reading correctly

Low refrigerant

charge

Check refrigerant system operation, check super heat and sub cooling are with in

normal operating ranges

H

ig

h

Ambi

ent

T

emp

Faulty probe

Check operation of transducer/reading correctly

Air Re-

circulation

Check condenser air is not recirculating back over the condenser coil

L

o

w

Ret

urn

Wa

ter

T

emp

Faulty probe

Check operation of transducer/reading correctly

Low Water

Flow

-Check water flow through plate pack heat exchanger is sufficient

- Check pump operation. Replace pump if at fault

Low refrigerant

charge

Check refrigerant system operation, check super heat and sub cooling are with in

normal operating ranges

Poor Heat Dissipation

While the condenser heat dissipation is poor, the compressor will be inefficient and the operating

current will be increased. When the chiller reaches the high pressure value (set depending on the

chiller type and refrigerant used), the high pressure switch will trip an alarm and the unit will stop

working. This can be caused by poor heat dissipation. For air-cooled chillers, confirm that the

condenser is not dirty or choked and have a good airflow. Once the above conditions are checked to

be in normal condition, clear the alarm. If the high pressure alarm is frequently occurring, clean the

condenser as soon as possible.

Low Refrigerant

If the pressure at the gauge is pressure low, it may indicate a shortage of refrigerant. Any leaks should

be filled, the dryer filter should be changed, and it should be drawing a vacuum again. Refill the

refrigerant after the above has been performed.

Содержание Thermal X R Series

Страница 29: ...User Manual Thermal X R Series Chillers Page 29 Installation Sketch Map of Air Cooled Chiller...

Страница 30: ...User Manual Thermal X R Series Chillers Page 30 Installation Sketch Map of Water Cooled Chiller...

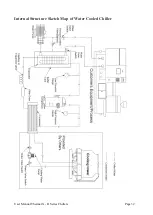

Страница 31: ...User Manual Thermal X R Series Chillers Page 31 Internal Structure Sketch Map of Air Cooled Chiller...

Страница 32: ...User Manual Thermal X R Series Chillers Page 32 Internal Structure Sketch Map of Water Cooled Chiller...