MANUAL DE INSTRUCCIONES

MARCA/ MAKE: AOKY TIPO

:

APILADOR ELECT. PBS1030W

EDICIÓN: 1º

19

5.3 Promote

Do not overload. The maximum load capacity of this car is 1000kg.

Only increase the load capacity allowed by the load curve.

When traveling, please the fork completely reduced to a car on the leg, and press the lift

button (Figure 1, 11) until you reach your expectations lifting height.

5.4 Down

If the fork is on the shelf, first carefully the vehicle together with the tray rack or separate

vehicles removed from shelves.

Carefully press the down button.

Goods will be reduced until the fork left tray rack, and then carefully pulled away from the

goods.

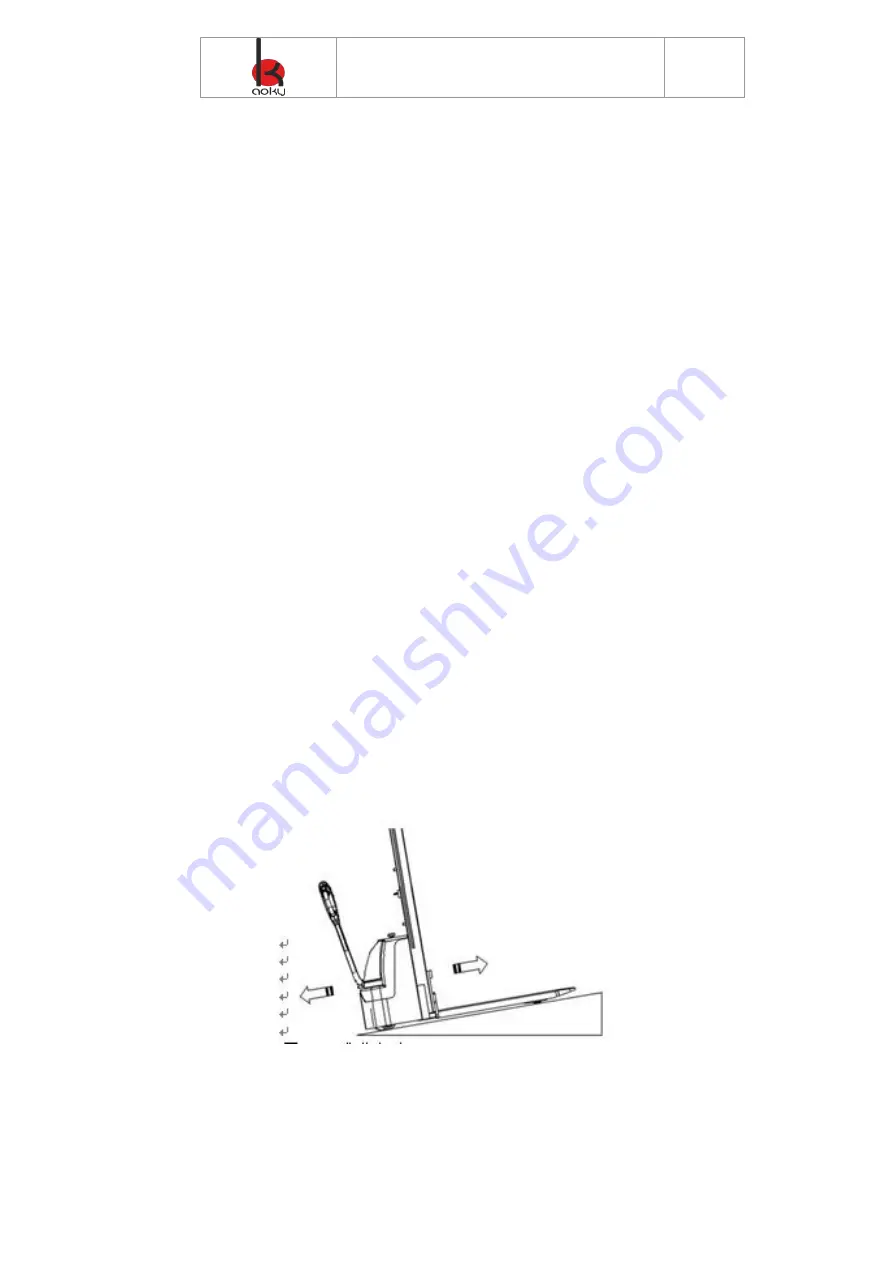

5.5Traveling

Only when the goods are upward only when running on slope.

Not to exceed the specified drive technology parameters on slope.

Only when the fork to lift point (<300MM), was allowed to travel

Fig 7: Goods up