®

P/N 1010455 Rev. K 10/20

9

Daily

NOTE:

Frequency of cleaning is de-

termined by water conditions,

usage, and water filtration

systems.

CAUTION

Chlorides or phosphates in cleaning

agents (such as bleach, sanitizers,

degreasers, or detergents) could cause

permanent damage to stainless steel

equipment. The damage is usually in

the form of discoloration, dulling of met-

al surface finish, pits, voids, holes, or

cracks. This damage is permanent and

not covered by warranty. The following

tips are recommended for maintenance

of your stainless steel equipment:

y

Always use a soft, damp

cloth for cleaning, rinse with

clear water, and wipe dry.

When required, always rub in

direction of metal polish lines.

y

Routine cleaning should be

done daily using soap, ammonia

detergent, and water.

y

Stains and spots should

be removed using a

vinegar solution.

y

Finger marks and smears

should be rubbed off

using soap and water.

y

Hard water spots should

be removed using a

vinegar solution.

1.

Turn the power off, unplug the power

cord, and allow the unit to cool down

before proceeding.

2.

Check the Water Pressure Regulator

gauge and verify that it reads 20–25

psi (1.4–1.7 kg/cm2 or 138–172

kPa). If not, adjust the pressure as

described in the Installation section

of this manual.

3.

Check the rear water Quick Discon-

nect Fitting and Hose Clamp for

leakage. Tighten clamps or replace

parts if needed.

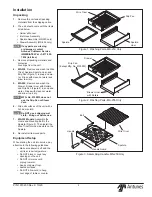

Maintenance

Drip Pan (Except Mfg. No. 9100933)

Drawer Liner

with Rollers

Drawer

Top

Cover

Steam Vent

(except Mfg.

No. 9100933)

Figure 9. Daily Cleaning–MS-250

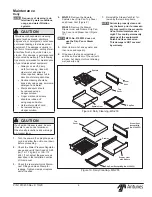

Figure 10. Daily Cleaning–MS-255

Spatula

Drip Pan

Spatula Liner

Top

Cover

Steam

Vent

4. MS-250

: Remove the Spatula,

Spatula Liner, Drip Pan, Top Cover,

and Steam Vent (Figure 9).

MS-255

: Remove the Drawer,

Drawer Liner with Rollers, Drip Pan,

Top Cover, and Steam Vent (Figure

10).

NOTE:

MFG. No. 9100933 does not

use the Drip Pan or Steam

Vent.

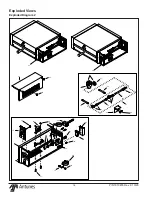

5.

Wash items in hot, soapy water and

then rinse and wipe dry.

6.

Wipe down the food compartment

and the entire exterior of the unit with

a clean, hot, damp cloth (not dripping

wet) and wipe dry.

CAUTION

If a chemical cleaner is used, be sure

it is safe to use on cast aluminum.

Observe all precautions and warnings

on product label.

7.

Reinstall the Steam Vent first, fol

-

lowed by the remaining items.

NOTE:

Failure to properly clean and

dry the items prior to reassem-

bly may result in the accumula-

tion of water/moisture over-

night. This could permanently

damage of the equipment’s

finish and its accessories.

This damage is NOT covered

by warranty.

Содержание 9100430

Страница 19: ... P N 1010455 Rev K 10 20 19 Notes ...