28

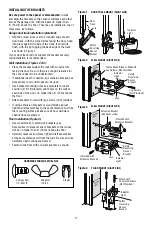

Using the Wall-Mounted Door Control

THE MULTI-FUNCTION DOOR CONTROL

Press the push button to open or close

the door. Press again to reverse the door

during the closing cycle or to stop the

door while it's opening.

Light feature:

Press the Light button to turn the opener

light on or off. It will not control the opener lights when

the door is in motion. If you turn it on and then activate the

opener, the light will remain on for 4-1/2 minutes. Press

again to turn it off sooner. The 4-1/2 minute interval can be

changed to 1-1/2, 2-1/2, or 3-1/2 minutes as follows: Press

and hold the Lock button until the light blinks (about 10

seconds). A single blink indicates that the timer is reset to

1-1/2 minutes. Repeat the procedure and the light will blink

twice, resetting the timer to 2-1/2 minutes. Repeat again

for a 3-1/2 minute interval, etc., up to a maximum of four

blinks and 4-1/2 minutes.

Lock feature:

Designed to prevent operation of the door

from hand-held remote controls. However, the door will

open and close from the Door Control, the Outside Keylock

and the Keyless Entry Accessories.

To activate, press and hold the Lock button for 2 seconds.

The push bar light will fl ash as long as the Lock feature is

on.

To turn off, press and hold the Lock button again for 2

seconds. The push bar light will stop fl ashing. The Lock

feature will also turn off whenever the “learn” button on the

motor unit panel is activated.

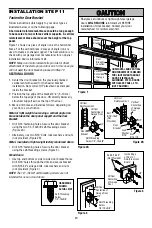

To Open the Door Manually

NOTICE: To comply with FCC and or Industry Canada (IC) rules,

adjustment or modifications of this receiver and/or transmitter are

prohibited, except for changing the code setting or replacing the

battery. THERE ARE NO OTHER USER SERVICEABLE PARTS.

Tested to Comply with FCC Standards FOR HOME OR OFFICE USE.

Operation is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired

operation.

To prevent possible SERIOUS INJURY or DEATH:

• NEVER allow small children near batteries.

• If battery is swallowed, immediately notify doctor.

To reduce risk of fi re, explosion or chemical burn:

• Replace ONLY with 3V2032 coin batteries.

• DO NOT recharge, disassemble, heat above 100° C

(212° F) or incinerate.

To prevent possible SERIOUS INJURY or DEATH from a

falling garage door:

• If possible, use emergency release handle to disengage

trolley ONLY when garage door is CLOSED. Weak or

broken springs or unbalanced door could result in an

open door falling rapidly and/or unexpectedly.

• NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

• NEVER use handle to pull door open or closed. If rope

knot becomes untied, you could fall.

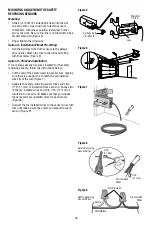

Care of Your Opener

LIMIT AND FORCE ADJUSTMENTS:

Weather conditions may cause some

minor changes in door operation

requiring some re-adjustments,

particularly during the fi rst year of

operation.

Pages 24 and 25 refer to the limit and force adjustments.

Only a screwdriver is required. Follow the instructions

carefully.

Repeat the safety reverse test (Adjustment Step 3,

page 26) after any adjustment of limits or force.

MAINTENANCE SCHEDULE

Every Month

• Manually operate door. If it is unbalanced or binding,

call a trained door systems technician.

• Check to be sure door opens and closes fully. Adjust

limits and/or force if necessary (see pages 24 and 25).

• Repeat the safety reverse test. Make any necessary

adjustments (see Adjustment Step 3).

Two Times a Year

• Check chain tension. Disconnect trolley fi rst. Adjust if

necessary (see page 7).

Every Year

• Oil door rollers, bearings and hinges. The opener does

not require additional lubrication. Do not grease the

door tracks.

Every Three to Four Years

• Use a rag to wipe away the existing grease from the

garage door opener rail. Reapply a small layer of white

lithium grease to the rail.

THE REMOTE CONTROL BATTERY

The lithium battery should

produce power for up to 5 years.

To replace battery, use the visor

clip or screwdriver blade to pry

open the case as shown. Insert

battery positive side up (+).

Dispose of old battery properly.

Replace the batteries with only

3V2032 coin cell batteries.

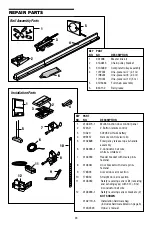

FORCE CONTROLS

LIMIT CONTROLS

Push

Button

Lock

Button

Light

Button

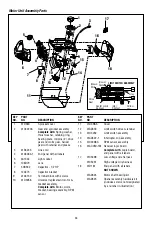

MANUAL DISCONNECT

POSITION

Trolley

Release

Arm

Emergency

Release

Handle

(Pull Down)

LOCKOUT POSITION

Trolley

Release

Arm

Emergency

Release

Handle

(Down and Back)

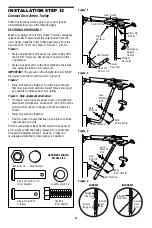

The door should be fully closed

if possible. Pull down on the

emergency release handle and lift the

door manually. To reconnect the door

to the opener, press the door control

push bar.

The

lockout feature

prevents

the trolley from reconnecting

automatically. Pull the emergency

release handle down and back

(toward the opener). The door can

then be raised and lowered manually

as often as necessary. To disengage

the lockout feature, pull the handle

straight down. The trolley will

reconnect on the next UP or DOWN

operation, either manually or by using

the door control or remote.