Specifications Information and Repair Parts Manual

3390-99 and 3391-99

3390-252-00.DOC 2

2/2015

3-Inch Solids-Handling Pedestal Pump

MAINTENANCE (Continued)

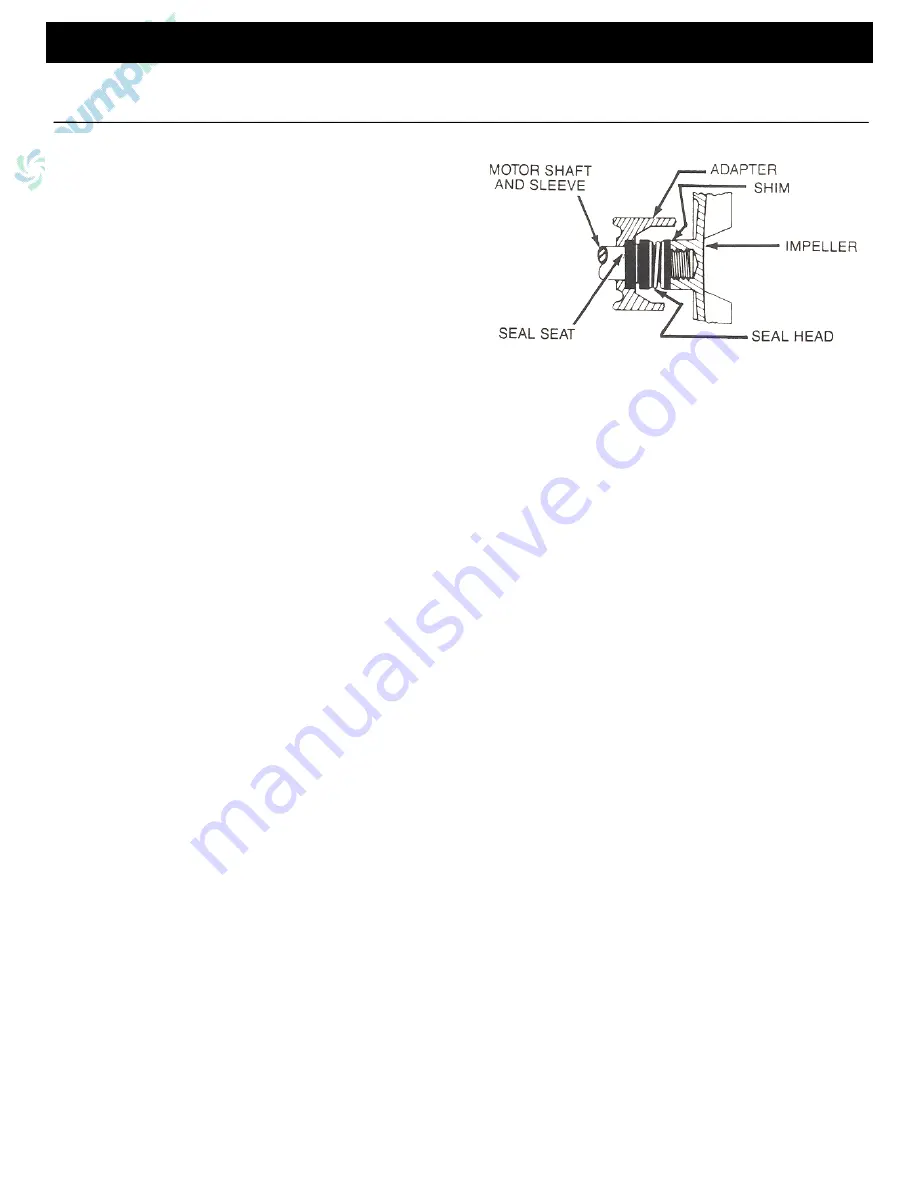

2.

Remove shaft sleeve with sea head on it. Separate seal head

from sleeve.

3.

Remove adapter from bearing housing (Ref. No. 14), then

using two screwdrivers or other suitable tools, remove seal

seat from adapter.

4.

Thoroughly clean all surfaces of seal seat cavity.

5.

Using a clean cloth, wipe shaft and shaft sleeve and make

certain that they are perfectly clean.

NOTE:

Do not touch or wipe polished face of seal head.

6.

Wet rubber portion of new seal seat with light coating of

soapy water. Press seal seat squarely into adapter recess.

Avoid scratching polished surface.

NOTE:

Handle all seal parts with extreme care and attention to keeping

them clean. Do not touch polished faces with your hands. Do not put

lubricants of any kind on seal faces; this can cause seal to leak.

7.

Inspect polished face of seal seat and polished face of seal

head to insure they are clean and not marred.

8.

Wet inside rubber portion of new seal head with a light

coating of soapy water. Slide head onto shaft sleeve.

IMPORTANT:

Before installing new shaft sleeve, apply a bead of non-

hardening, pliable sealant (such as Permatex® Form-A-Gasket® No. 2)

to motor shaft shoulder.

NOTE:

Reinstall any shims or spacers, which may have been removed,

onto pedestal shaft before installing impeller.

9.

Screw impeller back in place, tightening until it is against shaft

shoulder.

10.

Replace adapter, gasket and casing and fasten with eight cap

screws.

11.

After assembly, turn shaft by hand slowly to check for striking

of impeller on casing. If striking or rubbing occurs, adjust

impeller shims (see Shim Adjustment) as required.

12.

A short “run-in” period may be necessary to provide

completely leak free seal operation.

IMPELLER REPLACEMENT

Impeller (Ref. No. 6) and cutwater/wearplate (Ref. No. 3) are subject to

wear only by abrasive action of sandy or dirty fluid. If badly worn, all

these parts can be replaced easily, and pump thus restored to like-new

operation.

NOTE:

When clearance between impeller exceeds 1/16” at face of

impeller or 1/8” on outside diameter of impeller, it may be necessary to

take corrective action. The increased clearance can cause lengthened

priming times and reduced pumping capacity. If both priming and

capacity of your unit are satisfactory for your application, it is

recommended that no corrective maintenance be performed regardless

of what clearances on your unit may be developed, since the increased

clearances in themselves are not generally harmful to your pump.

Normally, new pump clearances can be restored by simply shimming

behind impeller. (Add shim washers Ref. No. 6)

If diameter of impeller is badly worn or is shim washers do not restore

clearances to less than 1/16” face dimension required, it is

recommended that impeller be replaced and refer to Figure 2.

1.

Detach pump casing (Ref. No. 2) and casing seal (Ref. No.

10)

2.

Remove two flat head socket screws (Ref. No. 4) in face of

cutwater/wearplate.

3.

Cutwater/wearplate can now be removed from casing.

4.

Simply reverse procedure to install replacement.

BEARING HOUSING SERVICE

1.

Remove front pump assembly as described under

“Mechanical Seal Replacement.”

2.

Remove shaft bearing (Ref. No. 17) and shaft (Ref. No. 18)

as an assembly by first removing snap ring (Ref. No. 20).

Push shaft bearing assembly out of bearing housing (Ref.

No. 14) by rapping on threaded end of shaft with a rawhide

mallet, or block of wood and hammer.

3.

Ball bearings can now be removed from shaft.

4.

If shaft bearings have been removed from shaft, replace by

sliding bearing on shaft to shoulder. Replace shaft bearing

assembly by sliding assembly into housing threaded end

first. Push shaft bearing assembly completely in by gently

tapping on keyway end of shaft with a rawhide mallet.

Replace snap ring.

5.

Reassemble pump as described in “Mechanical Seal

Replacement.”

SHIM ADJUSTMENT

1.

When installing a replacement impeller (Ref. No. 5) it may

be necessary to vary number of shims (Ref. No. 6) that will

be required. This is done by adding one shim more than

was removed and reassembling pump as described.

2.

Insure that casing is snugly in place and check shaft to

make sure it is turning freely. If it turns freely, check to

insure that adapter (Ref. No. 11) and casing (Ref. No. 2) are

fitted metal to metal where they meet on outside. If they are

not metal to metal, tighten cap screw (Ref. No. 12) and

recheck shaft for free turning. Tighten carefully, turning shaft

while tightening. If shaft seizes before cap screw are

completely tight, disassemble pump and remove one shim

and repeat reassembly.

3.

If at any time during above operation shaft does not turn

free or a metal to metal strike can be heard or felt when

turning shaft, follow procedure indicated above and repeat

procedure.

4.

Above procedure insures that pump will have proper

running clearance between impeller can casing and perform

like a new unit.

Figure 1- Mechanical Seal Replacement

Содержание 3390-99

Страница 4: ......