335A-250-00

2

3/2019

Specifications Information and Repair Parts Manual

335 Series and 336 Series

x

Diaphragm Pumps

exhaust line to the outside, regularly check the exhaust

system for leaks. Be sure the area is well ventilated.

7.

If the gas engine is equipped with a spark arrester screen in

the muffler, it should be inspected for wear periodically and

replaced when necessary.

Specific Safety Information for Electric Motor Driven

Pump

1.

This unit is not waterproof and is not intended to be used in

potentially wet locations. The motor is designed to be used in

a clean dry location with access to an adequate supply of

cooling air. Ambient temperature around the motor should not

exceed 104º F (40º C). For outdoor installations, motor must

be protected by a cover that does not block air flow to and

around the motor. This unit is not weatherproof nor is it able

to be submersed in water.

2.

When wiring an electrically driven pump, follow all electrical

and safety codes, as well as the most recent United States

National Electrical Code (NEC) and the Occupational Safety

and Health Act (OSHA).

Risk of electrical shock! Never connect the green (or green and

yellow) wire to a live terminal.

3.

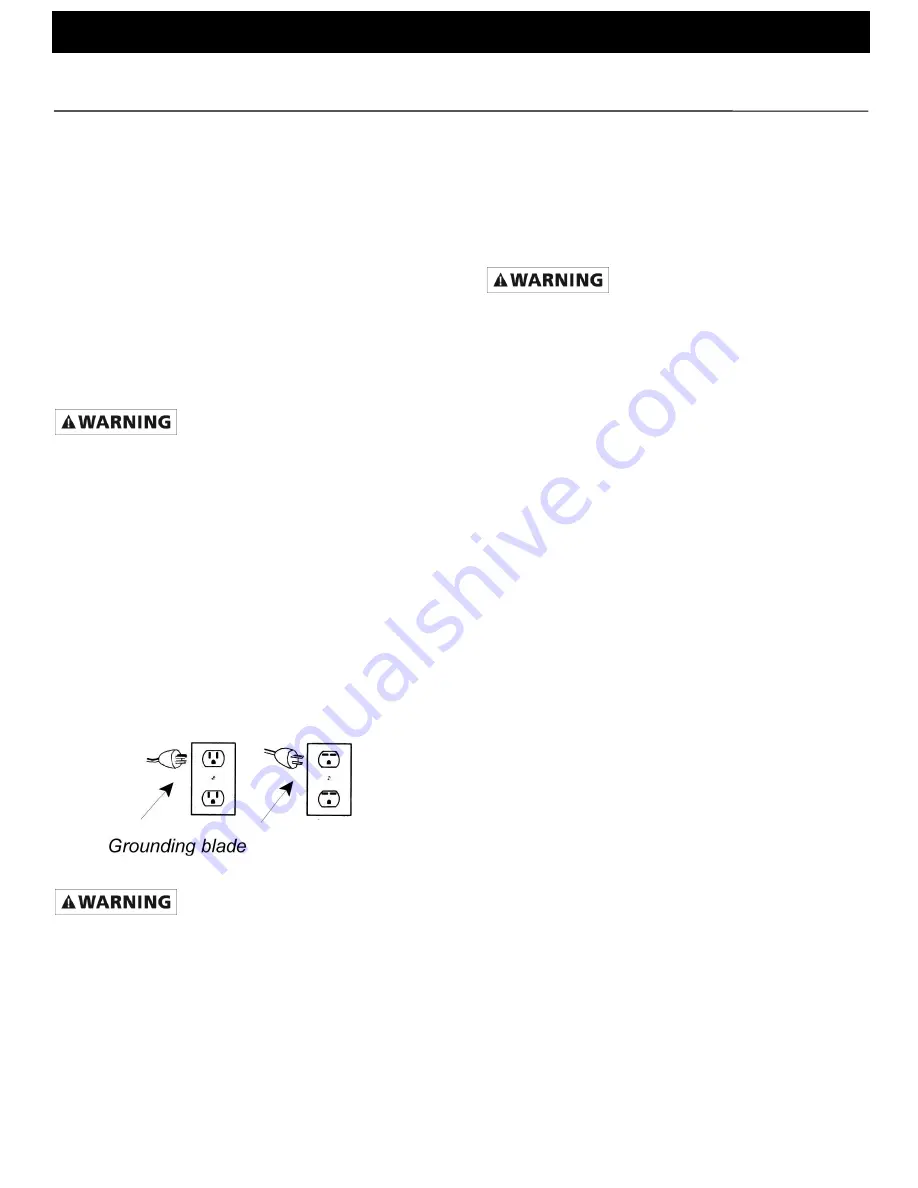

To reduce the risk of electric shock, the motor must be

securely

and

adequately

grounded!.

This

can

be

accomplished by either: (1) inserting plug (portable) directly

into a properly installed and grounded 3-prong grounding-type

receptacle (as shown in Figure 2); (2) permanently wiring the

unit with a grounded metal raceway system; (3) using a

separate ground wire connected to the bare metal of the

motor frame; or (4) other suitable means. The green (or green

and yellow) conductor in the cord is the grounding wire. The

motor must be securely and adequately grounded for your

protection against shock hazards! Where a 2-prong wall

receptacle is encountered, it must be replaced with a properly

grounded 3-prong receptacle with a grounded 3-prong

receptacle installed in accordance with the National Electrical

Code and local codes and ordinances. To ensure a proper

ground, the grounding means must be tested by a qualified

electrician. Use only 3-wire extension cords that have 3-

prong, grounding-type plugs and 3-pole receptacles that

accept the equipment plug.

4.

All wiring should be performed by a qualified electrician.

Figure 2 Grounding Methods

An incorrect connection may cause an electric short, produce an

electrical shock or burn out the pump motor, resulting in property

damage and/or personal injury.

5.

Protect electrical cord from sharp objects, hot surfaces, oil

and chemicals. Avoid kinking the cord. Replace or repair

damaged or worn cords immediately.

6.

Provide safety shields on all moving and electrical parts to

prevent personal injury.

7.

Keep fingers and foreign objects away from ventilation and

other openings. Do not insert any objects into the motor.

8.

Use wire of adequate size to minimize voltage drop at the

motor.

9.

Disconnect power before servicing a motor or its load. If the

power disconnect is out of sight, lock it in the open position

and tag it to prevent unexpected application of power.

10.

Do not touch an operating motor. Modern motors are

designed to operate at high temperatures.

General Safety Information (All Units)

1.

Know the pump application, limitations and potential

hazards.

Do not use to pump flammable or explosive fluids such as

gasoline, fuel oil, or kerosene, etc. Do not use in flammable

and/or explosive atmospheres. Pump should only be used with

liquids compatible with pump component materials. Failure to

follow this warning can result in personal injury and/or property

damage.

2.

Make certain that the power source conforms to the

requirements of your equipment.

3.

Provide adequate protection and guarding around moving

parts.

4.

Disconnect power before servicing.

5.

Release all pressure within the system before servicing any

component.

6.

Drain all liquids from the system before servicing.

7.

Secure the discharge line before starting the pump. An

unsecured discharge line will whip, possibly causing

personal injury and/or property damage.

8.

Check hoses for weak or worn condition before each use,

making certain that all connections are secure.

9.

Periodically inspect pump and system components. Perform

routine maintenance as required (see Maintenance

Section).

10.

Provide a means of pressure relief for pumps whose

discharge line can be shut off or obstructed.

11.

Personal Safety:

a.

Wear safety glasses at all times when working

with pumps.

b.

Wear a face shield and proper apparel when

pumping hazardous chemicals.

c.

Keep work area clean, uncluttered and properly

lighted - replace all unused tools and equipment.

d.

Keep visitors at a safe distance from the work

area.

e.

Make workshop childproof

– with padlocks,

master switches and by removing starter keys.

12.

For air drive units follow Safety Information in instruction

sheet supplied with air motor.

.

ASSEMBLY

1.

HANDLE ON 2" PUMP

(Refer to Figure A)

a.

Remove two hex cap screws (Ref. No. A6) and

washers (Ref. No. A7) from gearbox (Ref. No.

A1).

b.

Place handle (Ref. No. A35) on gearbox flange

and align holes.

c.

Reinstall two hex cap screws and washer

assemblies, then tighten.

HANDLE ON 3" PUMP

(Refer to Figure A)

d.

Remove two hex nuts from pump well (Ref. No.

A3).

e.

Place handle (Ref. No. A35) under pump well.

f.

Reinstall two hex nut and washer assemblies,

then tighten.

2.

ROTATING SUCTION/DISCHARGE PORTS (OPTIONAL)

(Refer to Figure A,W,P)