E. Start up procedures

1. Check that all fittings and hoses are securely attached, and that the

hoses are routed properly.

2. Check engine oil level. Fill to full mark if necessary.

3. Set vehicle parking brake, With transmission in park/neutral start the

engine and immediately check oil pressure. Note: Pressure may initially

take a moment or two to rise.

Caution:

Carefully check for leaks at fittings, hoses and mount. If leaks

are observed,

STOP ENGINE IMMEDIATELY

, repair leaks and continue.

4. After engine has warmed, shut off and re-check engine oil level. Fill as

necessary.

5. Record vehicle mileage/operating hours and date of installation.

F. Periodic maintenance

1. Periodic visual inspection of the fittings and hoses is recommended. Look

for leaks, hose deterioration and cuts. Repair and/or replace as necessary.

2. To change the filter element:

a. Ensure engine is off and use caution as the engine, oil and filter may

be hot and could result in an injury.

b. Using a filter wrench, remove the filter elements. Dispose of properly.

c. Clean the filter gasket contact areas on the mount with a clean, lint-

free rag.

d. Lubricate the new filter gaskets with clean oil or grease.

e. Fill filters as full as possible with engine oil.

f. Screw on new filters, tighten per instructions on filter can.

g. Start engine and check for leaks.

h. Check engine oil level, fill as needed.

3. Record vehicle mileage/operating hours for future reference.

Diesel Powered Engines:

Due to higher oil contamination levels in diesel

engines and variance in fuel quality, maintenance intervals for the filter ele-

ment and oil change intervals should be determined using oil analysis. For

more on oil analysis see the last page.

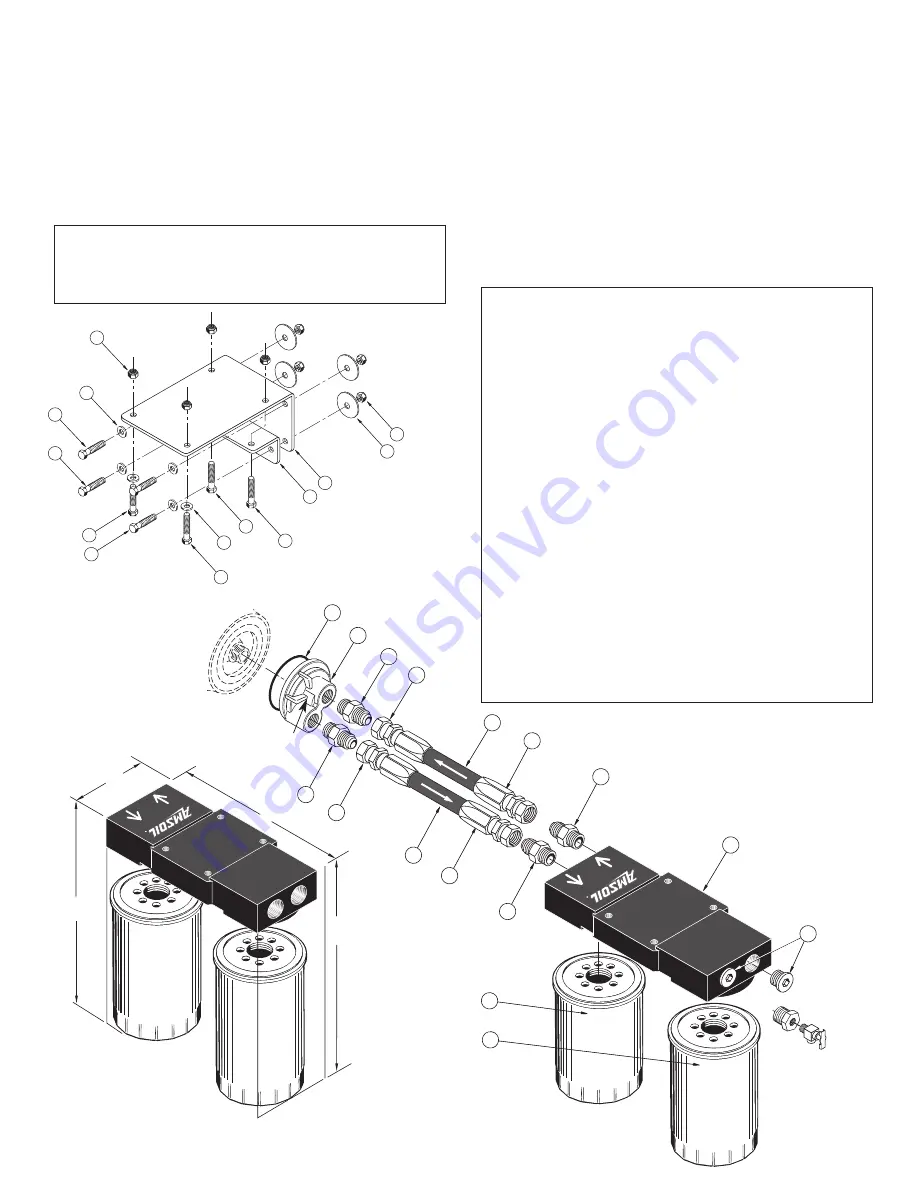

8

7

9

10

11

7

6

11

7

1

6

8

7

OUT

IN

17

16

2

12

15

5

13

4

14

14

14

3

3

3

14

4

5

EaBP-100

10

″

10

1

⁄

4

″

Ea0-26

5

″

9

″

Diagram A

MINIMUM AREA NEEDED FOR

DUAL MOUNT AND SPIN-ON OIL FILTER ELEMENTS

* Mount and element heights plus 1-inch removal clearance

Parts and assembly list

Item

Description

Qty.

Part No.

1.

Filter Mount Assembly

1

BK-209

2.

Allen Head Plug

2

BP-191

3.

1

⁄

4

20 x 1

Hex Head Bolt

4

BP-23

4.

1

⁄

4

I.D. Washer

6

BP-21

5.

1

⁄

4

-20 Self Locking Nuts

8

BP-22

6.

Adapter Fitting

1

⁄

2

NPT-

1

⁄

2

JIC

2

BP-201

7.

Hose Fitting

4

BP-260

8.

13

⁄

32

I.D. Hose

8

BP-250

9.

Spin-On Casting (Cummins) with “O” ring

1

BP-176

Spin-On Casting (International) with “O” ring

1

BP-177

Spin-On Casting (Duramax) with “O” ring

1

BP-219

10.

“O” Ring 2

1

⁄

2

I.D. (Cummins, Duramax)

1

BP-161

“O” Ring 3

5

⁄

8

I.D. (International)

1

BP-178

“O” Ring 3

1

⁄

8

I.D. (Duramax)

1

BP-162

11.

“O” Ring Fitting Adapter

3

⁄

4

-16 x

1

⁄

2

JIC

2

BP-189

12.

Mounting Bracket (top)

1

BP-194

13.

Mounting Bracket (bottom)

1

BP-195

14.

1

⁄

4

-20 x 1

1

⁄

2

Hex Head Bolt

4

BP-185

15.

1

⁄

4

I.D. Fender Washer

4

BP-186

16.

Full-Flow Filter

1

EaO-26

17.

By-Pass Filter

1

EaBP-100

Plastic Tie

2

BP-46

Thread Sealant

1

BP-198

Instruction Sheet

1

BP-174

Optional Parts Available From AMSOIL INC.

90° Fitting, Pack of 2

BK-11

45° Fitting, Pack of 2

BK-12

Oil Sampling Kit

BK-13

Diagram B

BMK-15 Ea, 16 Ea,

and 17 Ea

or optional

BK-13 Sampling

Kit

AMSOIL

By-Pass Filter

EaBP-100

AMSOIL

Full-Flow Filter

EaO-26

Red

Indicator

BP174 83642 8/23/06 8:22 AM Page 2