9

Temposonics

®

GB-Series SSI

Operation Manual

Installation of GB with pressure fit flange

Mount the sensor via pressure fit flange through the bores in the

sensor electronics housing with 6 machine screws M6×16 A2-70

(ISO 4762).

Fig. 4:

Installation of GB with pressure fit flange »S« & »N«

Fig. 5:

Sensor in cylinder

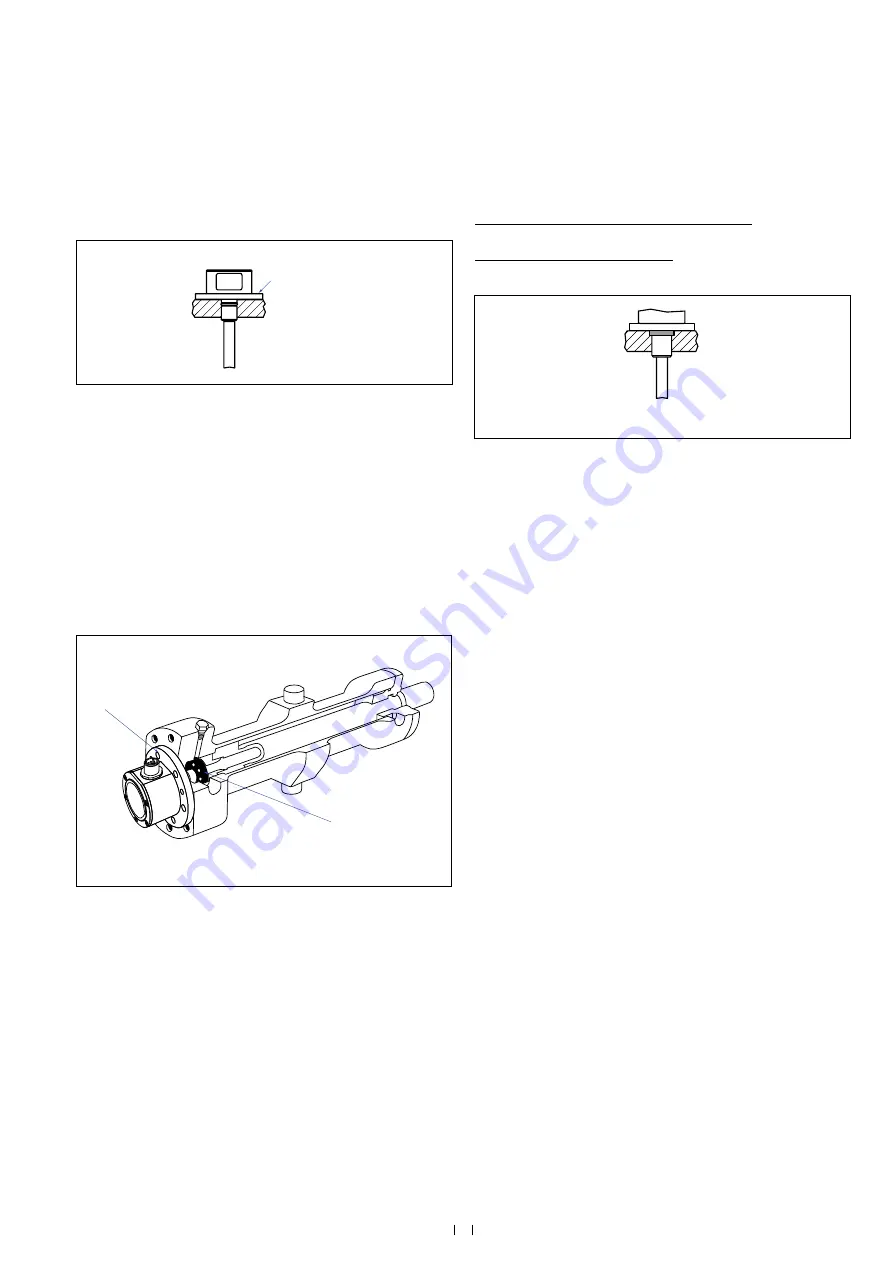

Installation of a rod-style sensor in a

hydraulic

cylinder

The rod-style version has been developed for direct stroke measure-

ment in a

hydraulic

cylinder. Mount the sensor through the bores in

the sensor electronics housing with 6 machine screws M6×16 A2-70

(ISO 4762).

• Mounted on the face of the piston, the position magnet travels

over the rod without touching it and indicates the exact position

through the rod wall – independent of the hydraulic fluid.

• The pressure resistant sensor rod is installed into a bore in the

piston rod.

Hydraulics sealing

Seal the flange contact surface via O-ring in the undercut as shown in

For pressure fit flange Ø18 f7 (GB-K / GB-N / GB-S):

O-ring 15 × 2 mm (0.59 x 0.02 in.) (part no. 560 853)

For pressure fit flange Ø21 f6 (GB-J):

O-Ring 17 × 2 mm (0.67 x 0.02 in.) (part no. 561 438)

Fig. 6: Sealing

•

Note the fastening torque of machine screws of 6 Nm.

•

Seat the flange contact surface completely on the cylinder mounting

surface.

• The cylinder manufacturer determines the pressure-resistant

gasket (copper gasket, O-ring, etc.).

• The position magnet should not grind on the sensor rod.

•

The piston rod drilling (GB-N / GB-S: ≥ Ø 13 mm (≥ Ø 0.52 in.),

GB-J / GB-K: ≥ Ø 16 mm (≥ Ø 0.63 in.)) depends on the pressure

and piston speed.

• Adhere to the information relating to operating pressure.

• Protect the sensor rod against wear.

Fastening torque

6 Nm

Sensor electronics housing

with sensor rod

Position magnet

Sealing via O-ring

in the flange undercut