46-622 Series 3 Liquid Level Switches ASME B31.3 Construction

15

4.2.2 Check Sensing Unit

1. Reconnect power supply. Carefully actuate the switch

mechanism manually (use a non-conductive tool on elec-

trical switch mechanisms) to determine whether controlled

equipment will operate.

Caution:

With electrical power on, avoid contact with switch leads

and connections at terminal block.

2. If controlled equipment responds to manual switch actua-

tion test, trouble may be located in the level sensing por-

tion of the control, float(s), stem(s), and magnetic attrac-

tion sleeve(s).

3. Check to be certain liquid is entering float chamber.

A valve may be closed or piping plugged.

Caution:

Be certain to pull disconnect switch or otherwise ensure

that electrical circuit(s) through control is deactivated.

Close operating medium supply valve on controls

equipped with pneumatic switch mechanisms.

4. Disconnect wiring from supply side of switch mechanism(s)

and remove electrical conduit or operating medium line

connections to switch housing.

5. Perform system shutdown to relieve pressure from float

chamber of control and allow unit to cool.

6. Close shutoff valves (if equipped) to isolate control from

vessel. Drain off liquid in chamber if necessary

7. On installations without shutoff valves, relieve pressure

from vessel and drain off liquid head above control

mounting level.

NOTE: Control chamber, connections, and pipe lines need not be

removed from vessel or boiler.

8. Remove switch housing assembly by loosening enclosing

tube hex nut, which is located immediately below housing

base. Refer to

Figure 6

on 8.

9. With switch housing assembly removed, inspect attraction

sleeve(s) and inside of enclosing tube for excessive corrosion

or solids buildup, which could restrict movement, prevent-

ing sleeve(s) from reaching field of switch magnet(s).

10. If differential has been changed in the field by reposition-

ing the lower jam nuts on the float stem, check tightness

and position of the jam nuts.

11. Check float to be certain it is buoyant in the liquid (float

chamber or vessel must have adequate liquid level). If float

is determined to be filled with liquid, or it is collapsed, it

must be replaced immediately.

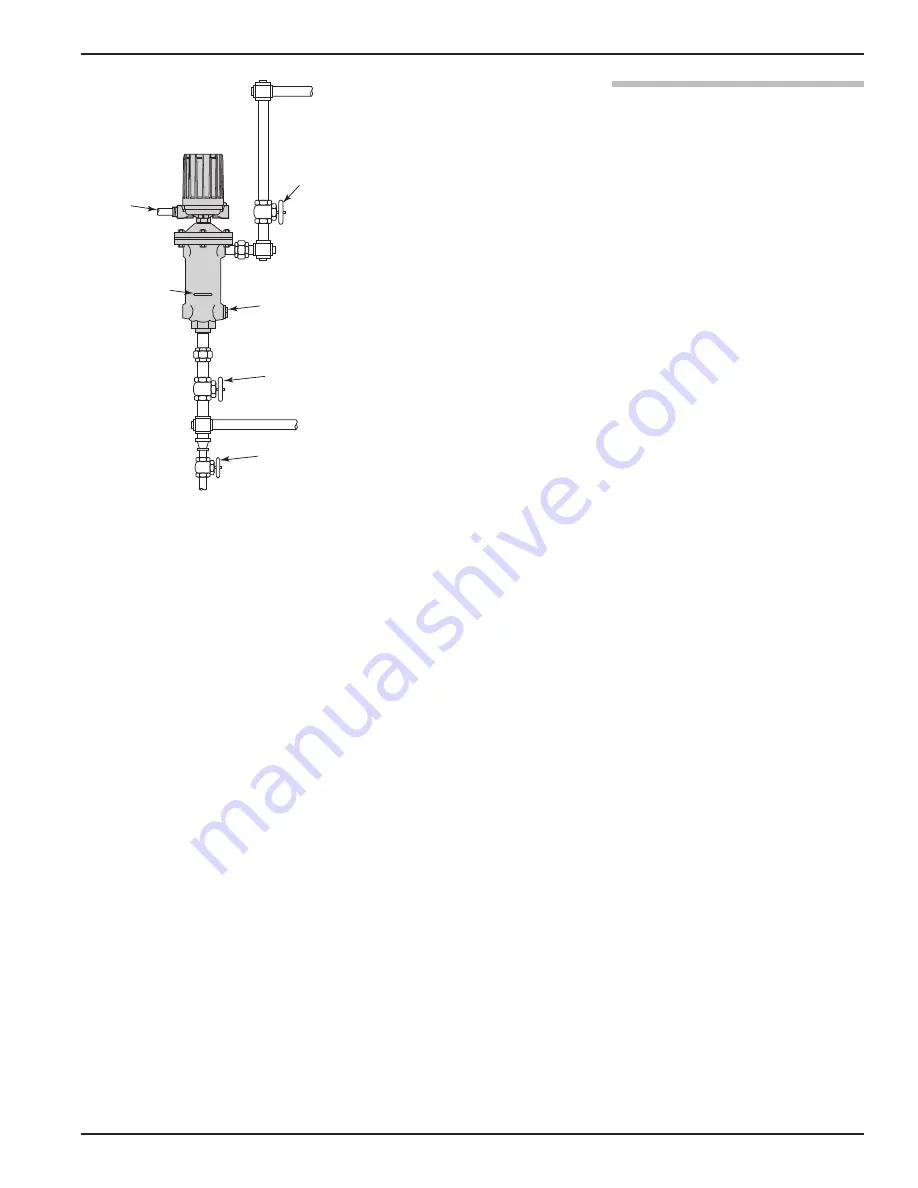

Optional blow-down

or drain valve

Shutoff valve

(if used)

Conduit

outlet

Switch

actuating

level reference

mark

Optional liquid leg

connection to vessel

Shutoff valve

(if used)

Figure 11