4

2

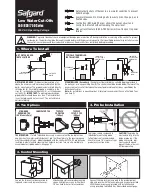

MOUNT CONTROL BOX; Fig. 4

Important: For AC installation, make sure power

supply connector is inserted into control box

through power supply grommet before control box

is mounted to the wall. Reference electrical

installation section (pages 5 & 6).

1. Determine location of CONTROL BOX (3). It must be

located with-in the 14" (356mm) by 21" (533mm)

shaded area shown in Figure 4 in order for electrical

connections from the spout assembly to be made.

NOTE: CONTROL BOX SUPPLY HOSE is 20". Distance

between wall supply and CONTROL BOX (3) must be

taken into consideration.

2. Remove tape from CONTROL BOX COVER (1)

and pull off COVER

(1). Hold the CONTROL BOX (3)

in desired location and mark the four mounting hole

locations as shown.

Fig. 4.

NOTE: Find plastic bag containing 4 M5X16 screws to be

used for securing the CONTROL BOX COVER (1) when

installation is complete.

NOTE: For AC installation, make power supply

connection before mounting CONTROL BOX (3) to wall.

3. It is recommended that the CONTROL BOX (3) be

secured to a wall stud or cross brace within the wall

using the SCREWS

(16) supplied. If the CONTROL BOX

(3) is to be installed on tile or plaster walls, the

ANCHORS

(17) and SCREWS (16) should be used.

3

CONNECT SPOUT HOSE TO

CONTROL BOX; Fig. 5

1. Connect SUPPLY NUT (18) from spout hose to nipple

on top of CONTROL BOX

(3). Tighten with adjustable

wrench to make a water tight connection.

Fig. 3.

4

CONNECT WATER SUPPLY TO

CONTROL BOX AND WALL

SUPPLY; Fig. 6, 6a

NOTE; If using the optional Mixing Valve See Sheet

#M968808 for installation instructions.

1. Insert FIBER WASHER (19) into SUPPLY NUT (18) on

CONTROL BOX

(3).

2. Connect FLEXIBLE SUPPLY HOSE (20) to SUPPLY NUT

(18) on CONTROL BOX (3). Tighten to make a water tight

connection. Use two wrenches to tighten if necessary.

Fig. 6.

3. Connect FLEXIBLE SUPPLY HOSE (20) directly to wall

supply. Connection on FLEXIBLE SUPPLY HOSE

(20) is

3/8" compression. Use adjustable wrench to tighten

connection. Do not over tighten.

Fig. 6a.

Note: FLEXIBLE SUPPLY HOSE (20) measures 20" from the

bottom of the CONTROL BOX (3) base. If additional supply

length is required, installer must purchase parts separately.

Important: If FLEXIBLE SUPPLY HOSE (20) is too long, loop

to avoid kinking.

M965612 Rev. 1.8 (12/17)

Fig. 4

1524mm

(60")

14"

(356mm)

3-3/4"

(96mm)

2-3/4"

(71mm)

3"

(76mm)

21"

(mm)

1

17

16

3

20"

(500mm)

MOUNTING HOLES

SUPPLIES

WASTE

ENCLOSURE

MOUNTING

HOLES

LAVATORY RIM OR

MOUNTING SURFACE

Fig. 5

18

3

18

3

20

Fig. 6

3

COLD WATER OR

TEMPERED

WALL SUPPLY

Fig. 6a

19

!