18-CE15D1-1C-EN

23

Duct Connections

Air duct systems should be installed in accordance with standards for

air conditioning systems, National Fire Protection Association

Pamphlet No. 90. They should be sized in accordance with ACCA

Manual D or whichever is applicable. Check on controls to make

certain they are correct for the electrical supply.

Central furnaces, when used in connection with cooling units, shall be

installed in parallel or on the upstream side of the cooling units to

avoid condensation in the heating element, unless the furnace has

been specifically approved for downstream installation. With a parallel

flow arrangement, the dampers or other means used to control flow of

air shall be adequate to prevent chilled air from entering the furnace,

and if manually operated, must be equipped with means to prevent

operation of either unit unless the damper is in full heat or cool

position.

Flexible connections of nonflammable material may be used for return

air and discharge connections to reduce the transmission of vibration.

Though these units have been specifically designed for quiet, vibration

free operation, air ducts can act as sounding boards and could, if

poorly installed, amplify the slightest vibration to the annoyance level.

When the furnace is located in a utility room adjacent to the living

area, the system should be carefully designed with returns which

minimize noise transmission through the return air grille. Although

these winter air conditioners are designed with large blowers

operating at moderate speeds, any blower moving a high volume of

air will produce audible noise which could be objectionable when the

unit is located very close to a living area. It is often advisable to route

the return air ducts under the floor or through the attic. Such design

permits the installation of air return remote from the living area (i.e.

central hall).

When the furnace is installed so that the supply ducts carry air

circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by a duct(s) sealed to the

furnace and terminating outside the space containing the furnace.

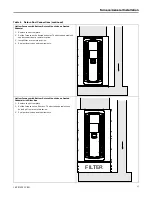

For furnaces not equipped with a cooling coil, it is recommended that

the outlet duct be provided with a removable access panel. The

opening shall be accessible when the furnace is installed and shall be

of such a size that the heat exchanger can be viewed for possible

openings using light assistance or a probe can be inserted for

sampling the air stream. The removable cover must be sealed to

prevent air leaks.

Where there is no complete return duct system, the return

connection must be run full size from the Furnace to a location

outside the utility room, basement, attic, or crawl space.

Do Not

install return air through the back of the Furnace cabinet.

Do Not

install return air through the side of the furnace cabinet on

horizontal applications without following the guidelines in the Return

Air Filters section in the figure for Horizontal furnace with side return.

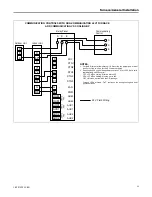

Carbon monoxide, fire or smoke can cause serious bodily injury,

death, and/or property damage.

A variety of potential sources of carbon monoxide can be found in a

building or dwelling such as gas-fired clothes dryers, gas cooking

stoves, water heaters, furnaces and fireplaces. The U.S. Consumer

Product Safety Commission recommends that users of gas-burning

appliances install carbon monoxide detectors as well as fire and

smoke detectors per the manufactures installation instructions to help

alert dwelling occupants of the presence of fire, smoke or unsafe

levels of carbon monoxide. These devices should be listed by

Underwriters Laboratories, Inc.

Standards for Single and Multiple

Station Carbon Monoxide Alarms, UL 2034.

Note:

The manufacturer of your Furnace DOES NOT test any

detectors and makes no representations regarding any brand

or type of detector.

Note:

Seal per local codes

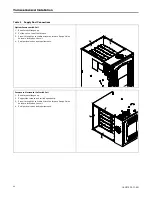

In horizontal applications, the furnace must be supported with one of

the following methods.

1.

Support below with non-combustible material as shown in the

illustration.

2.

Use BAYHANG kit. See kit instructions.

3.

Use unistrut with cabling to provide support from under the unit.

4.

Use strapping material in locations shown in illustration.

Note:

When supporting from underneath, unit must have 1.5"

minimum air clearance. Block the minimum amount of vent

holes as possible.

WHEN SUSPENDING THE HORIZONTAL

FURNACE, IT SHOULD BE SUSPENDED

BY ATTACHING TO THE CABINET

IN THE PLACES SHOWN.

WHEN SUPPORTING THE

FURNACE FROM BELOW,

SUPPORT FRONT TO

BACK (AS SHOWN)

OR SIDE TO SIDE.