507788-01

Issue 2007

Page 12 of 20

Electrical Connections

Electric shock hazard! - Disconnect all power

supplies before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical

shock.

WARNING

Run 24V Class II wiring only through specified low

voltage opening. Run line voltage wiring only through

specified high voltage opening. Do not combine voltage

in one opening.

WARNING

Electric Shock Hazard.

Can cause injury or death.

Foil-faced insulation has conductive

characteristics similar to metal. Be sure there

are no electrical connections within 1/2ʺ of the

insulation. If the foil-faced insulation comes in

contact with electrical voltage, the foil could

provide a path for current to pass through

to the outer metal cabinet. While the current

produced may not be enough to trip existing

electrical safety devices (e.g., fuses or circuit

breakers), the current can be enough to cause

an electrical shock hazard that could cause

personal injury or death.

WARNING

Electric Shock Hazard. Can cause injury or

death. Unit must be properly grounded in

accordance with national and local codes.

Line voltage is present at all components when

unit is not in operation on units with single-

pole contactors. Disconnect all remote electric

power supplies before opening access panel.

Unit may have multiple power supplies.

WARNING

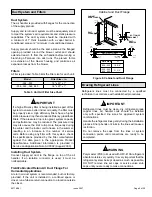

• Wiring must conform to the current National Electric

Code, ANSI/NFPA No. 70, or Canadian Electric Code

Part I, CSA Standard C22.1, and local building codes.

Refer to following wiring diagrams. See unit nameplate

for minimum circuit ampacity and maximum over-

current protection size.

•

Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer

to the air handler rating plate for maximum over-

current protection, minimum circuit ampacity, as well

as operating voltage. Select the proper supply circuit

conductors in accordance with tables 310-16 and 310-

17 in the National Electric Code, ANSI/NFPA No. 70 or

tables 1 through 4 in the Canadian Electric Code, Part

I, CSA Standard C22.1.

•

The power supply must be sized and protected

according to the specifications supplied on the product.

•

This air handler is factory-configured for 240 volt,

single phase, 60 cycles. For 208-volt applications, see

“208 Volt Conversion” later in this section.

•

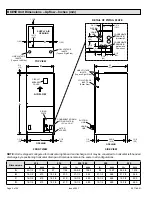

Separate openings have been provided for 24V low

voltage and line voltage. Refer to the dimension

illustration of specific location.

•

This unit is provided with holes for conduit. Use

provided caps to seal holes not used.

•

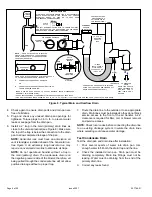

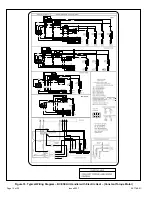

Typical unit wiring (as well as wiring of optional field-

installed electric heat) is given in Figure 16. Refer to

the instructions provided with the electric heat section

for proper installation.

USE COPPER CONDUCTORS ONLY

WARNING

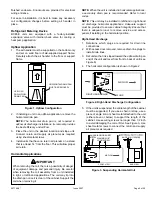

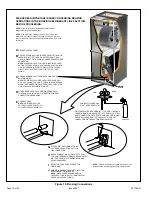

1.

Disconnect all power supplies.

2. Remove the air handler access panel.

3.

Route the field supply wires to the air handler electrical

connection box.

4.

Use UL-listed wire nuts to connect the field supply

conductors to the unit black and yellow leads, and the

ground wire to ground terminal marked GND.

5. Replace the air handler access panel.

End Panel

Side

Figure 11. Electrical Connections

(Upflow Configuration)