506762-03

Page 16 of 18

Issue 1946

Maintenance

Regular Maintenance Requirements

Your system should be regularly inspected by a qualified

service technician. These regular visits may include

(among other things) checks for:

• Motor operation

• Ductwork air leaks

• Coil & drain pan cleanliness (indoor & outdoor)

• Electrical component operation & wiring check

• Proper refrigerant level & refrigerant leaks

•

Proper airflow

• Drainage of condensate

•

Air filter(s) performance

• Blower wheel alignment, balance & cleaning

• Primary & secondary drain line cleanliness

• Proper defrost operation (heat pumps)

Air Filter

Inspect air filters at least monthly and replace or clean as

required. Disposable filters should be replaced. Washable

filters may be cleaned by soaking in mild detergent and

rinsing with cold water. Allow filter to dry before reinstalling.

Replace filters with the arrows pointing in the direction of

airflow. Dirty filters are the most common cause of poor

heating / cooling performance and compressor failures.

Indoor Coil

If the system has been operated with a clean filter in place,

it should require minimal cleaning. If cleaning is needed,

call your dealer for service.

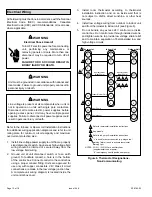

Condensate Drain

During cooling season check at least monthly for free flow

of drainage and clean if necessary.

Condenser Coils

Grass cuttings, leaves, dirt, dust, lint from clothes dryers,

and foliage from trees can be drawn into coils by movement

of the air. Clogged condenser coils will lower the efficiency

of your unit and could cause damage to the condenser.

Periodically, debris should be brushed from the condenser

coils. Use a soft bristle brush with light pressure only. DO

NOT damage or bend condenser coil fins. Damaged or

bent fins may affect unit operation.

SHARP OBJECT HAZARD!

Condenser coils have sharp edges. Wear adequate

body protection on body extremities (e.g. gloves).

FAILURE TO FOLLOW THIS WARNING COULD

RESULT IN BODILY INJURY.

WARNING

Painted Surfaces

For maximum protection of the unit’s finish, a good grade

of automobile wax should be applied every year. In

geographical areas where water has a high concentration

of minerals (calcium, iron, sulfur, etc.), it is recommended

that lawn sprinklers not be allowed to spray the unit. In

such applications, the sprinklers should be directed away

from the unit. Failure to follow this precaution may result

in premature deterioration of the unit finish and metal

components.

In sea coast areas, special maintenance is required due

to the corrosive atmosphere provided by the high salt

concentration in ocean mists and the air. Periodic washing

of all exposed surfaces and coil will add additional life to

your unit. Please consult your installing dealer for proper

procedures in your geographic area.

Homeowner Information

ELECTRICAL SHOCK HAZARD!

Turn OFF electric power to unit before performing any

maintenance or removing panels or doors.

FAILURE TO DO SO COULD RESULT IN BODILY

INJURY OR DEATH.

WARNING

Heat Pump Operation

Your new heat pump has several characteristics that you

should be aware of:

• Heat pumps satisfy heating demand by delivering large

amounts of warm air into the living space. This is quite

different from gas-or oil-fired furnaces or an electric

furnace which deliver lower volumes of considerably

hotter air to heat the space.

• Do not be alarmed if you notice frost on the outdoor coil

in the winter months. Frost develops on the outdoor

coil during the heating cycle when temperatures are

below 45°F. An electronic control activates a defrost

cycle lasting 5 to 15 minutes at preset intervals to clear

the outdoor coil of the frost.