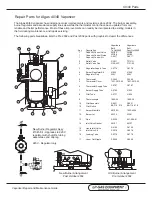

Installation Example

Vapor Bypass

Regulator

Liquid

Oil

Separator

First Stage

Regulator

Burner Supply

Line

Supplemental

Relief Valve

Vapor

To Load

Storage

Tank

6

0

0

W

O

G

600 WOG

600 WOG

Vaporizer Installation Best Practices

Distances from vaporizer

Storage tank

Storage shutoffs

Point of transfer

Buildings

10 feet

15 feet

15 feet

25 feet

Notes

All piping must follow the guidelines of NFPA 58.

The liquid tank opening shows an internal valve

allowing two-way liquid flow. The boiling liquid and

expanding vapor in the vaporizer chamber requires

this two-way flow capability.

The system has a first stage regulator on the dis-

charge of the vaporizer and a vapor bypass regulator

on the tank vapor outlet valve. The bypass regulator

is normally set slightly lower and only delivers vapor

to the system if the vaporizer quits functioning.

The vaporizer burner supply line is optional but

highly recommended. Pulling cold vapor directly from

the storage tank greatly alleviates clogged controls,

pilots etc. in the vaporizer from oily heavy ends.

The oil separator shown piped in after the first stage

regulator removes the oily mist from the vapor stream

before it can enter the load piping. To avoid reconden-

sation of the propane vapor, the separator must be

piped after the first stage regulator.

The supplemental relief valve shown is required

to protect the downstream system from over-

pressure conditions and liquid formation in the first

stage piping. Because most industrial first stage

regulators do not provide adequate relief protection,

this relief is nearly always mandatory.

Vaporizer Repair and Maintenance Guide

The following sketch depicts a typical vaporizer installation. The vaporizer system, when

piped as shown, will provide long trouble free vapor service. The vaporizer can be

isolated for maintenence or repair without interrupting the load.

Although some of the components such as the vapor bypass regulator, the burner supply

line and the oil separator are optional, they are all highly recommended as

"Best Practice

Piping"

for direct fired vaporizers.