3

ROUTINE MAINTENANCE INSTRUCTIONS

The.following.maintenance.procedures.will.extend.the.service.life.of.this.appliance .

WARNING:

.

Maintenance.should.not.be.performed.while.flowing.water ..Disconnect.from.water.supply.prior.to.

maintenance .

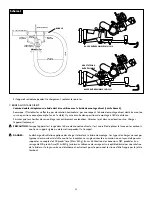

A .. Piston.Rod.Lubrication.-.Lightly.grease.each.end.of.the.piston.rod.with.Parker-O-Lube.or.equivalent.barium.grease.when.it.

becomes.dry.or.every.three.(3).months ..When.greased.properly,.the.rod.will.have.an.evenly.dispersed.layer.of.grease.covering.

the.exposed.portion.of.the.rod ..Distribute.grease.evenly.by.pushing.the.outlet.back.and.forth .

B .. Safety.Straps.-.Examine.strap.for.wear.and.make.sure.both.hooks.easily.snap.into.the.front.leg.clips ..If.straps.need.

replacement,.contact.your.local.Akron.Brass.Distributor .

C .. Every.six.months,.lightly.grease.the.threaded.portion.of.the.elevation.brake.knob.with.Parker-O-Lube.or.equivalent.. .

barium.grease .

D ... Examine.the.points.of.the.ground.spikes.in.the.portable.base ..If.the.flat.of.any.spike.exceeds.

1

⁄

16

”.(1 .5mm).diameter,.it.must.be.

sharpened.or.replaced ..To.sharpen,.use.a.flat.file.or.grinder.and.maintain.the.same.taper.as.the.original.spikes ..If.a.grinder.is.

used,.do.not.allow.the.spikes.to.become.hot,.or.change.color,.since.this.will.reduce.the.hardness.and.will.not.remain.sharp..

in.service .

E ... Check.the.spring.loaded.spike.holders.in.the.portable.base.to.ensure.that.they.move.freely ..Use.a.dry.spray.lubricant.if.

lubrication.is.required .

F ... Check.that.the.elevation.safety.stop.operates.properly ..This.stop.must.be.released.to.lower.the.unit.below.45˚.elevation .

G ... Check.both.the.inlet.clappers.function.properly.on.the.Dual.Inlet.Base ..Lubrication.is.not.normally.required.in.this.area .

H ... Check.that.the.latch.of.the.safety.chain.hook.engages.properly.in.the.chain .

I ... If.any.of.the.parts.do.not.function.properly,.contact.Akron.Brass.for.repair.instructions.or.return.the.unit.to.either.Akron.Brass.

Company.or.Akron.Manufacturing.Company .

TROUBLESHOOTING

If.the.unit.fails.to.operate.properly.or.stops:

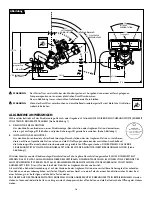

A .. Check.oscillation.ON/OFF.knob ..Make.sure.knob.is.pulled.out .

B .. Check.operating.pressure ..Make.certain.an.operating.pressure.of.at.least.70.PSI.(438.kpa,.4 .83.bar).is.maintained .

C .. Check.travel.control.knobs ..Do.not.place.both.travel.control.knobs.on.the.center.position.at.the.same.time ..If.you.want.to.

stop.the.oscillation,.depress.the.oscillation.ON/OFF.knob.as.previously.described.in.the.Operating.Instructions,.Section.C .

D .. If.the.unit.stops.during.operation,.lower.the.line.pressure.to.zero,.push.the.discharge.outlet.against.the.left.stop..

.

and.repressurize .

Содержание OZZIEMASTER 922

Страница 2: ......