AIWA VX-T1480

Mechanical Adjustments

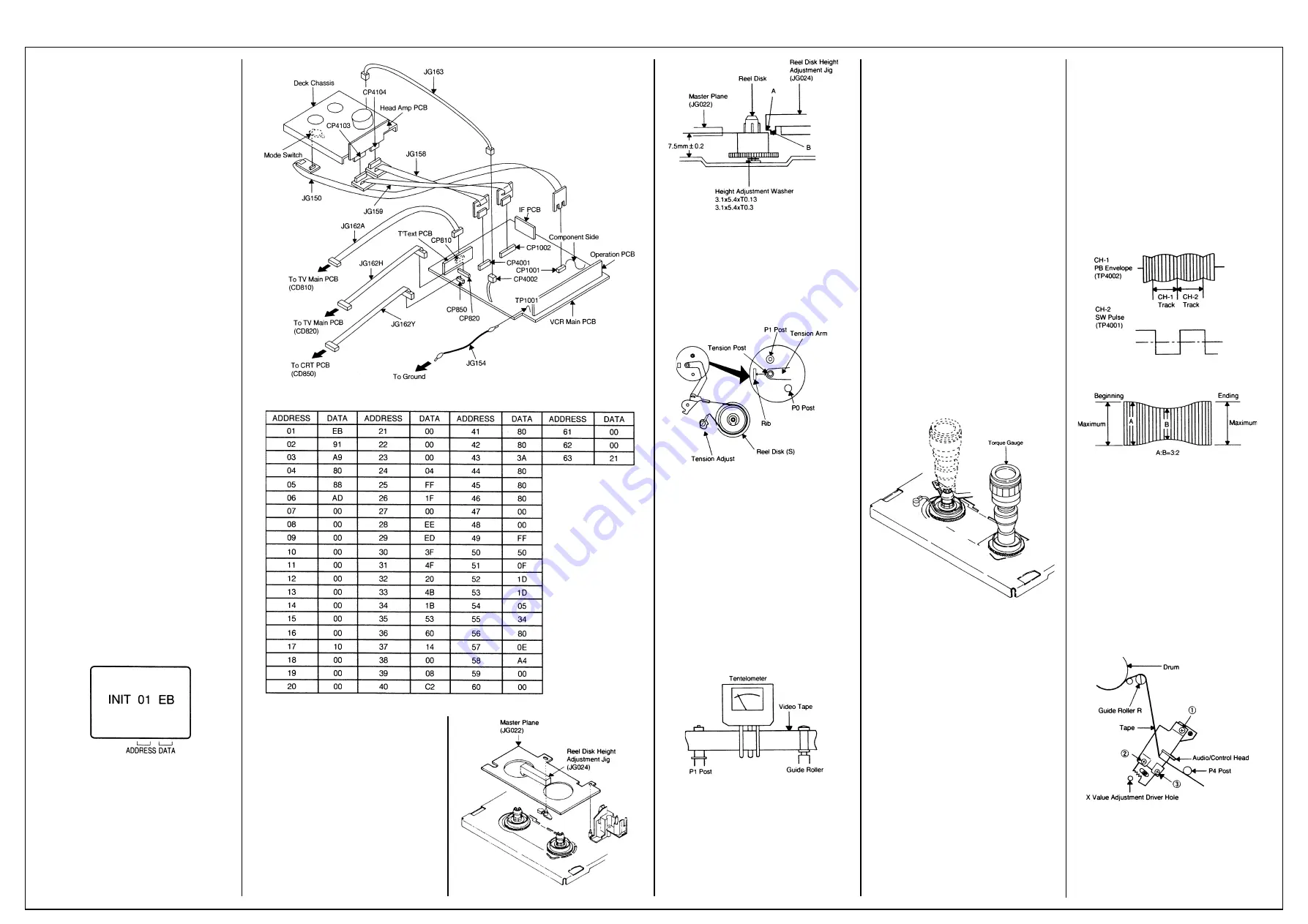

SERVICING PREPARATION

How to use the servicing fixture

1. Remove the VCR Main PCB from the Deck

Chassis.

2. Connect as shown in the figure using the

Service Fixture.

• Connect the VCR Main PCB to the Mode

Switch with the cable JG150.

• Connect the VCR Main PCB to the Head Amp

PCB with the cable JG158 and JG159.

• Connect the VCR Main PCB to the TV Main

PCB with the cable JG162A and JG 162H.

• Connect the VCR Main PCB to the CRT PCB

with the cable JG162Y.

• Connect the VCR Main PCB to the FE Head

with the cable JG163.

3. Short circuit between TP1001 and Ground

with the cable JG154. (Refer to MAJOR

COMPONENTS LOCATION GUIDE)

4. The EOT, BOT and Reel Sensor do not work

at this moment.

5. At that time, the STOP/EJECT button is

available to insert and eject the Cassette

Tape.

INSTRUCTIONS

1. Unplug the AC cord once and the clock will be

non-setting.

2. Turn on the POWER and set the VOLUME to

minimum.

NOTE:

If the Auto Set Up Function is working, the unit

cannot be operated. In this case, release the

Function or wait until the Function goes to the

end.

3. Press the VOL. DOWN button on the set and

the Channel button (6) on the remote control

simultaneously. The Fig. 1 appears on the

display.

4. Press the SET +/- button on the remote

control to modify the address and check the

data.

(Refer to Table 1)

5. After checking, turn off the Power.

(If the wrong data is input)

6. Press the SET +/- button on the remote

control to set to the address of the wrong

data, then press the ENTER button. The data

will bink. (Refer to Fig. 1)

7. Press the SET +/- button on the remote

control to set to the correct data, then press

the ENTER button. (Refer to Table 1)

8. Repeat the above steps 6 and 7 and input the

data into the each Address.

9. After the data input, turn off the Power.

Fig. 1

1. CONFIRMATION AND ADJUSTMENT

Read the following NOTED items before starting

work.

• Place an object which weighs between 350g

and 500g on the Cassette Tape to keep it

steady when you want to make the tape run

without the Front Loading Unit 6. (Do not

place an object which weighs over 500g.)

Reel Disk (S)

• When you activate the deck without the Front

Loading Unit 6, short circuit between TP1001

and Ground. In this condition the BOT/EOT/

Reel Sensor will not function.

1-1: CONFIRMATION AND ADJUSTMENT OF

REEL DISK HEIGHT

1. Turn on the power and set to the STOP

mode.

2. Set the master plane (JG022) and reel disk

height adjustment jig (JG024) on mechanism

framework, taking care not to scratch the

drum, as shown in Fig. 1-1-A.

3. Confirm that the reel disk is lower than “A” of

the reel disk height adjustment jig (JG024) on

the master plane and higher than “B” as

shown in Fig. 1-1-B. If it is not, adjust to less

than 7.5mm

±

0.2mm with the height adjust-

ment washer.

4. Perform the same adjustment for other reel.

Fig. 1-1-A

Fig. 1-1-B

1-2: CONFIRMATION AND ADJUSTMENT OF

TENSION POST POSITION

1. Turn on the power and set to the PLAY mode

adjust the Tension so that the Tension Post is

at the position of 0.3mm~0.5mm from the Rib.

(Refer to Fig. 1-2)

2. Confirm that the video tape is not curling at

the flange of P1 post or is not running on

flanges.

Fig. 1-2

1-3: CONFIRMATION AND ADJUSTMENT OF

BACK TENSION ON PLAYBACK

1. Load a video tape recorded in standard speed

mode. Set the unit to the PLAY mode.

2. Install the tentelometer as shown in Fig. 1-3.

Confirm the value is within 20~27gr/cm at this

time.

IN CASE OF USING A CASSETTE TYPE

TORQUE TAPE.

1. After adjustment, confirm and adjust the

tension post position (Refer to item 1-2) for

the tension arm, install the cassette type

torque tape (JG100A) and set to the PLAY

mode.

2. Confirm that the left hand side tension value

of the torque tape is 25~38gr/cm for the

standard mode tape.

Fig. 1-3

1-4: CONFIRMATION OF FAST FORWARD

TORQUE

1. Set torque gauge (JG002G) on take-up reel

disk, and place unit in FAST FORWARD

mode. (Refer to Fig. 1-4)

2. Confirm that torque is more than 400gr/cm.

NOTE

After setting the torque gauge on the reel disk,

hold the gauge in place. Push the FAST

FORWARD button and the reel disk will begin to

turn.

1-5: CONFIRMATION OF REWIND TORQUE

1. Operate within 4 or 5 seconds after the reel

disk begins to turn.

2. Set torque gauge (JG002G) on supply reel

disk, and place the unit in REWIND mode.

(Refer to Fig 1-4).

3. Confirm that torque is more than 400gr/cm.

NOTE

After setting the torque gauge on the reel disk,

hold the gauge in place.

Push the REWIND button and the reel disk will

begin to turn.

1-6: CONFIRMATION OF REEL BRAKE

TORQUE

(Take-Up Reel Brake) (Refer to Fig. 1-4)

1. Set to STOP mode.

2. Set the torque gauge (JG002G) to the take-

up reel and turn it counterclockwise.

3. Confirm that it is more than 200gr/cm at that

time.

(Supply Reel Brake) (Refer to Fig. 1-4)

1. Set to STOP mode.

2. Set the torque gauge (JG002G) to the supply

reel and turn it clockwise.

3. Confirm that it is more than 200gr/cm at that

time.

NOTE

Separate the idler from the reel and confirm the

brake torque.

Fig. 1-4

2-1: GUIDE ROLLER

NOTE

If the torque value checked is out of tolerance,

replace the appropriate parts as follows.

Check Items

Replace Parts

1-4

Idler Ass’y or Clutch Ass’y

1-5

Idler Ass’y or Clutch Ass’y

1-6

Main Brake T Ass’y or Main Brake S Ass’y

2. TAPE RUNNING CONFIRMATION AND

ADJUSTMENT

Tape running is adjusted precisely at the factory.

Normally, it is not necessary to make adjust-

ments. It is necessary to confirm and make

adjustments when the parts of the tape running

mechanism are replaced because of extensive

usage or failure.

2-1: GUIDE ROLLER

1. Connect CH-1 on the oscilloscope to TP4002

(PB Envelope) and CH-2 to TP4001 (SW

Pulse).

2. Set the tracking to manual center position in

the following way. Press and hold the tracking

auto button more than 2 seconds to set the

tracking to center position.

3. Trigger with SW pulse and observe the

envelope. (Refer to Fig. 2-1-A)

4. Adjust the guide roller height while observing

the envelope, and make the envelope flat.

Adjust the envelope so that the flatness will

not be affected even when the tracking control

button is pressed. (Use the adjustment

screwdriver JG005).

5. Press and hold the tracking control button

and (at the point that the envelope waveform

starts to reduce) adjust the envelope so that

the A:B ratio is better than 3:2. (Refer to Fig.

2-1-B)

6. Adjust the PG shifter (ELECTRICAL ADJUST-

MENTS : ITEM 3-1) in the PLAY mode.

NOTE

After adjustment, confirm and adjust A/C head

tilt. (Refer to item 2-2)

Fig. 2-1-A

Fig. 2-1-B

2-2: CONFIRMATION AND ADJUSTMENT OF

A/C HEAD TILT

When the tape is running abnormally, perform

the following adjustments.

1. Insert a new tape and play it back.

2. Confirm that there is no crease on the tape

between the P4 post and guide roller (R) and

the tape is running smoothly. (It is absolutely

impossible to get satisfactory sound if the

tape is distorted between the A/C head and

P4 post.)

3. If the tape still does not run smoothly, turn the

screw (1) and adjust the tilt of the A/C head.

(Refer to Fig. 2-2)

Fig. 2-2

2-3: ADJUSTMENT OF A/C HEAD HEIGHT

AND AZIMUTH

1. Playback a VHS alignment tape (JG001C)

and observe the waveform at the audio output

terminal.

2. Turn the screw (2) slowly to change the

Содержание VX-T1480

Страница 6: ...AIWA VX T1480 OVD 5 Deck Alternative Parts Cont d...

Страница 7: ...AIWA VX T1480 OVD 5 Deck Alternative Parts Cont d Earphone Diagram...

Страница 9: ...AIWA VX T1480 Chroma Diagram...

Страница 10: ...AIWA VX T1480 CRT Diagram...

Страница 11: ...AIWA VX T1480 Deflection Diagram...

Страница 12: ...AIWA VX T1480 Microcontroller Diagram...

Страница 13: ...AIWA VX T1480 Head Amp Diagram...

Страница 14: ...AIWA VX T1480 IF PCB Diagram...

Страница 15: ...AIWA VX T1480 Operations Diagram 1...

Страница 16: ...AIWA VX T1480 Operations Diagram 2 Audio Amp Diagram...

Страница 17: ...AIWA VX T1480 Power Diagram TV...

Страница 18: ...AIWA VX T1480 Power Diagram VCR...

Страница 19: ...AIWA VX T1480 Teletext Diagram...

Страница 20: ...AIWA VX T1480 Y C Diagram...

Страница 21: ...AIWA VX T1480 Tuner Audio Diagram...

Страница 22: ...AIWA VX T1480 Waveforms...

Страница 23: ...AIWA VX T1480 Wiring Diagram...

Страница 24: ...AIWA VX T1480 System Control Servo Diagram...