11

MAINTENANCE

CAUTION

The brush cutter was designed to cut weeds, grass and similar soft vegetation. Never use the trimmer for any other

application.

1 Cleaning air cleaner

An air cleaner had cogitation the fuel will be thicker.

lowing out and causing the engine to stop.

Wash the cleaner as required.

Replace the cleaner when it became dirty.

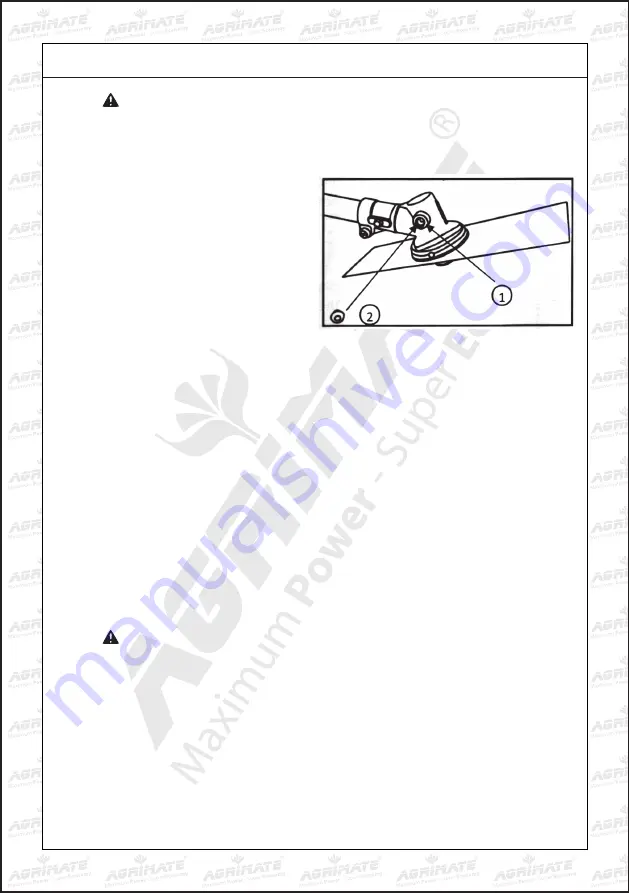

2 Lubricating the gear box with grease

The gear box has a greasing port

. Remove the greasing

ports screw

and feed grease into port.

Supply grease to the gear box through the grease port

every 30 hours. Fig.

3 Checking gear box mounting screws

Loose fixing screws are very dangerous even though they have covers to prevent them from coming off. Be sure to check

them before operating the brush cutter. Tight the screws securely with the hexagon wrench provided with the brush cutter.

4 Spark plug

The Spark plug have a standard electrode-to-electrode distance of 0.6 to 0.7 mm.

The Spark plug electrodes are dry and drown under optimum conditions. Clean as necessary. Use spark plug designated

for the engine.

5 Fuel strainer cleaning

The fuel has a fuel strainer at its end (in the fuel tank) to prevent foreign matter such as sand from entering the carburetor.

Clean the strainer as required because the pump cannot suck up fuel if the strainer is clogged, which would cause the

engine to stop, replace the felt strainer if it is clogged or damaged.

6 Adjusting throttle cable

Adjust the throttle cable length with the adjusting nut. If the cutting head rotates even after you have released your hand

from the throttle trigger to idle the engine. Adjust the throttle cable length.

7 Carburetor

CAUTION

The engine has been adjusted before shipment. In the case of engine trouble, contact your dealer because the engine

trouble is not caused by a faulty carburetor only. An engine that is not adjust properly will damage not only the carburetor

but also the engine itself.

8 Cleaning muffler

Cleaning muffler carbon after 50 hours of operation as below:

1 Remove the muffler guard and muffler.

2 To prevent carbon from enter the cylinder, pull the starter to turn the crankshaft, blocking the exhaust opening with the

piston.