4-18

TROUBLESHOOTING

PROCEDURES

4-20 Post Repair Calibration

the EEPROM chip (U211), each output in the supply must

be recalibrated as described in Appendix A of the Operating

Manual. Since the EEPROM provides non-volatile storage of

reassign these values before the calibration procedures can

key as described in Section III of the Operating Manual. The

supply's Model number is set as described in the next

paragraph.

4-21 Setting the Model Number

At turn-on, the supply's model number and letter suffix (e.g.

Agilent 6624A) are read out of the EEPROM along with

other constants which are required to program the supply

correctly. The model number constant specifies how many

and what type of outputs (e.g. 40 W or 80 W, etc.) your

supply contains and thus establishes the programming

limits for a particular supply.

The MODEL command is used to set the model number and

letter suffix of the supply. This was done before your supply

To assign a model number to your supply, the following

controller. Note that in this programming example, it is

Model 6624A.

4-13

GPIB BOARD AND FRONT PANEL

If the GPIB board is replaced or it is repaired by replacing

the supply's Model number and GPIB address, you must

be performed on the new (or repaired) GPIB board. The

GPIB address is set manually using the front panel ADDR

left the factory. However, when you replace a defective

GPIB board or repair an GPIB board by changing its

EEPROM chip (U211), this setting may be lost and you must

set the model number using the MODEL command.

short program can be used with BASIC installed in an GPIB

assumed that the GPIB Interface address is 7 and the

supply's GPIB address is 05 and your supply is a Agilent

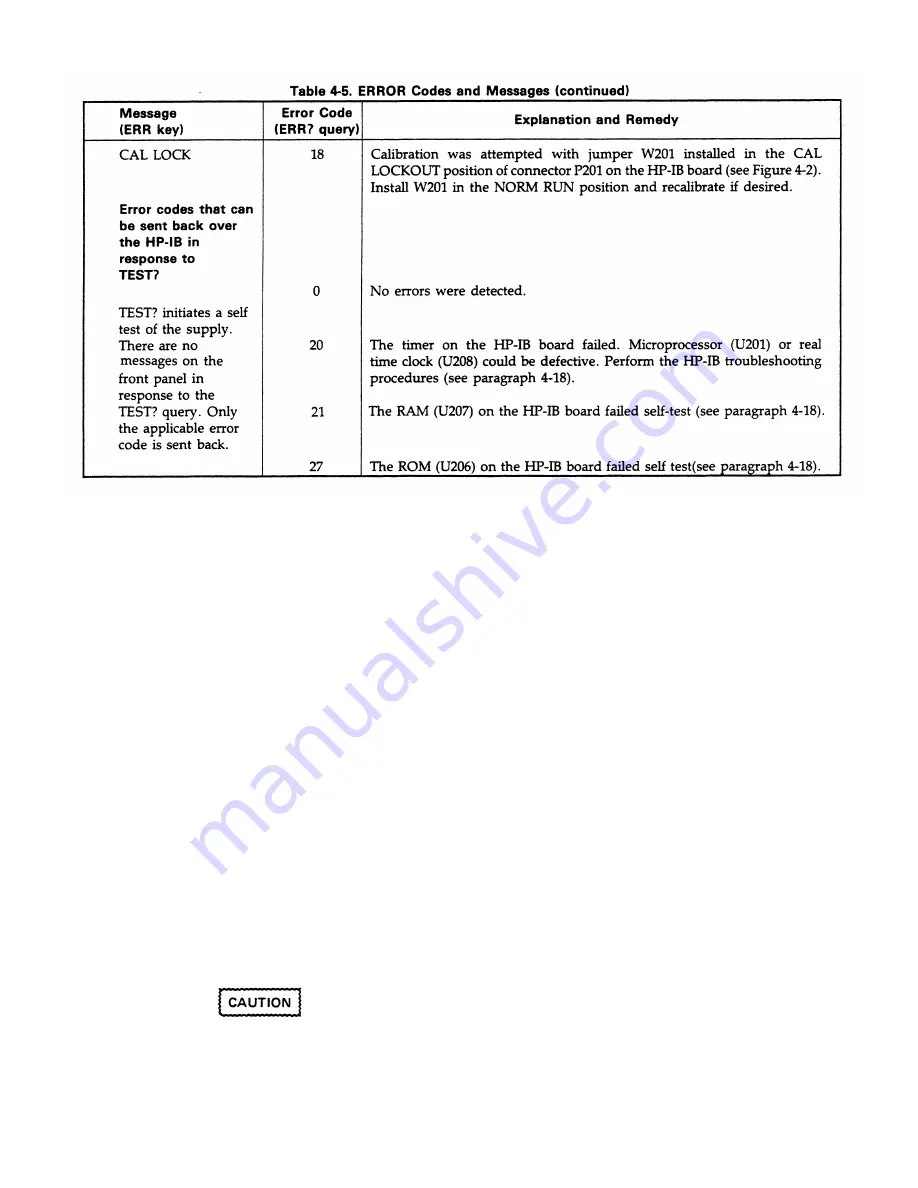

Troubleshooting procedures for the

G

PIB board and Front

procedures

first ensure that the bias voltages for the

G

PIB

board circuits and the Front Panel display are correct. The

microprocessor clock, the RAM, and ROM circuits are then

checked. After these preliminary checks are made, signature

analysis tests are performed as described in paragraph 4-22

to determine which component is defective.

4-19 Test Setup

The following test setup allows access to the components on

the

G

PIB board:

a. Disconnect the line cord.

b. Remove the

G

PIB board as described in

paragraphs 4-3 through 4-6.

c. Place an insulating material on the chassis and lay

the

G

PIB board on top of the material.

d. Reconnect all cables in their proper locations.

e. Connect the line cord.

The GPIB board is connected to the chassis ground with one PC

board screw and through the GPIB connector. When checking the

GPIB board with an oscilloscope, be sure that the scope's ground

is connected only to a ground point on the GPIB board itself.

Connecting the scope ground to any other point on the GPIB

board may result in damage to the supply.

NOTE:

The GPIB troubleshooting procedures in this section apply only to

earlier through-hole board assemblies. Surface-mount GPIB

assemblies are not repairable to the component level. If defective,

the entire GPIB assembly must be replaced.

Panel are given in the flow chart of Figure 4-7. The

Содержание 6621A

Страница 12: ...2 2...

Страница 16: ...2 6...

Страница 19: ...2 9...

Страница 22: ...2 12...

Страница 25: ...Figure 2 7 Typical Output Range Characteristics 2 15...

Страница 28: ...2 18...

Страница 30: ...3 2...

Страница 31: ...3 3...

Страница 44: ...3 16...

Страница 45: ...3 17...

Страница 48: ...4 3...

Страница 51: ...4 6...

Страница 55: ...4 10...

Страница 56: ...4 11...

Страница 57: ...4 12...

Страница 60: ...4 15...

Страница 61: ...4 16...

Страница 62: ...4 17...

Страница 63: ...4 18...

Страница 64: ...4 19...

Страница 65: ...4 20...

Страница 67: ...4 22...

Страница 68: ...4 23...

Страница 70: ...4 25...

Страница 71: ...4 26...

Страница 72: ...4 27...

Страница 73: ...4 28...

Страница 74: ...4 29...

Страница 76: ......

Страница 77: ...4 32...

Страница 78: ...4 33...

Страница 79: ...4 34...

Страница 80: ...4 35...

Страница 81: ...4 36...

Страница 82: ...4 37...

Страница 83: ...4 38...

Страница 84: ...4 39...

Страница 85: ...4 40...

Страница 86: ...4 41...

Страница 87: ...4 42...

Страница 88: ...4 43...

Страница 89: ...4 44...

Страница 90: ...4 45...

Страница 91: ...4 46...

Страница 92: ...4 47...

Страница 93: ...4 48...

Страница 98: ...4 53...

Страница 100: ...4 55...

Страница 101: ...4 56...

Страница 102: ...4 57...

Страница 103: ...4 58...

Страница 128: ...6 2...

Страница 129: ...6 3...

Страница 131: ...Figure 6 1 Power Distribution Schematic sheet 1 of 2 6 5...

Страница 132: ...Figure 6 1 Power Distribution Schematic sheet 2 of 2 6 6...

Страница 135: ...Figure 6 3 Output 1 2 Board Component Location 6 9...

Страница 136: ...Figure 6 3 Output 1 2 Board Schematic Diagram sheet 1 of 4 6 10...

Страница 137: ...Figure 6 3 Output 1 2 Board Schematic Diagram sheet 2 of 4 6 11...

Страница 138: ...Figure 6 3 Output 1 2 Board Schematic Diagram sheet 3 of 4 6 12...

Страница 139: ...Figure 6 3 Output 1 2 Board Schematic Diagram sheet 4 of 4 6 13...

Страница 140: ...Figure 6 4 Output 3 4 Board Component Location 6 15...

Страница 141: ...Figure 6 4 Output 3 4 Board Schematic Diagram sheet 1 of 4 6 16...

Страница 142: ...Figure 6 4 Output 3 4 Board Schematic Diagram sheet 2 of 4 6 17...

Страница 143: ...Figure 6 4 Output 3 4 Board Schematic Diagram sheet 3 of 4 6 3 6 18...

Страница 144: ...Figure 6 4 Output 3 4 Board Schematic Diagram sheet 4 of 4 6 3 6 19...

Страница 145: ...Figure 6 5 Output 1 2 80W Board Component Location 6 21...

Страница 146: ...Figure 6 5 Output 1 2 80W Board Schematic Diagram sheet 1 of 4 6 22...

Страница 147: ...Figure 6 5 Output 1 2 80W Board Schematic Diagram sheet 2 of 4 6 23...

Страница 148: ...Figure 6 5 Output 1 2 80W Board Schematic Diagram sheet 3 of 4 6 24...

Страница 149: ...Figure 6 5 Output 1 2 80W Board Schematic Diagram sheet 4 of 4 6 25...

Страница 151: ...A 2...

Страница 152: ...A 3...