2.2 CONNECTION TO A GAS SUPPLY

The gas supply piping and connection to the

appliance must be installed in accordance with the

various regulations listed on the front page of this

document.

2.3 CONNECTION TO AN ELECTRICAL SUPPLY

The electrical connections must comply with the

relevant standards listed on the front page of this

document.

2.4 CONNECTION TO A WATER SUPPLY

Not applicable to these appliances.

2.5 PRE-COMMISSIONING CHECK

Ensure that all open-top burners (where applicable)

and oven linings are properly located, and that oven

grid-shelves slide in and out easily. Check that all

packing material has been removed.

It is necessary for the gas pressure to be checked

before the unit is commissioned, and a suitable

pressure gauge must be connected to the pressure

test point(s) as follows:

Open Top Burners (where applicable).

Pull off the gas tap knobs, and remove the control

panel, thus revealing the test-point.

Ovens

FIRST ENSURE ELECTRICITY SUPPLY IS OFF

Remove the three Pozidriv screws securing the black

control panel, and draw the panel forward on its

slides. Remove the burner grille (4 Pozidriv screws).

Connect a pressure gauge to the outlet test point

immediately below the multifunctional gas control.

Note that inlet and outlet points are provided on the

control also.

The gas pressure to the open-top burners is adjusted

by means of the external governor mounted at the

rear of the appliance, whilst the oven pressure is

controlled by adjusting the appropriate screw on the

gas control-valve.

When adjusting the pressure on a range (i.e. G1102)

it is recommended that the oven, and two of the open

top burners be lit during the operation.

2.5.2 Adjusting The Oven Burner Pressure

Proceed as follows:

a) If possible, purge the supply lines of air. On G1102

ranges, this is simply effected by opening one or

two of the open top burner taps and applying a light

to the burner. On oven units, it may be necessary

to slacken off a joint in the incoming supply pipe,

taking care to re-tighten.

b) Light the oven, as described in the accompanying

User's Instructions. At this stage, take care not to

touch live connections which are now exposed

behind the withdrawn oven control panel.

c) Check all connections for gas-soundness, using

soap and water solution.

d) With the pressure gauge connected to the outlet

pressure test point adjust the pressure, which

should be 15 mbar (6 in w.g.), by turning the screw

in the regulator screw on the gas control. This is

situated under the white plastic cover, which must

be pulled off. To increase the pressure, turn the

screw clockwise, and vice-versa.

e) Adjust the open-top burner pressure by turning the

screw in the governor turret. Replace the protective

cap afterwards.

f) Switch off the appliance by depressing the OFF

button on the gas control valve, and turn off the

electricity supply at the mains. Replace test point

screws, control panels etc.

2.5.3 Checking The Performance Of

The Controls

Oven

a) Light the oven as detailed in the User's

Instructions, set the thermostat at 250

o

C and

allow the oven to heat up, ensuring that the fan is

operating and turning anti-clockwise when viewed

from the front.

b) Turn the thermostat down to its lowest setting, and

check that the oven burner goes out, but leaving

the pilot burner lit.

c) Turn the thermostat knob to a high setting,

whereupon the oven burner should re-light

smoothly and with little or no delay.

d) Check that the fan stops, and the oven burner goes

out, when the oven doors are opened.

e) Check the operation of the power switch. When

OFF the fan should stop, and the main burner be

extinguished. The pilot burner, however, remains

lit.

f) Check to timer. This does not turn off the gas to the

oven, but simply provides the user with an audible

sign that a pre-set time has elapsed.

g) Depress the oven light button and check hat the

light is operational.

Open Top

Light the open top as detailed in the User's Instruc-

tions. Check that the ignition is smoooth and without

delay. Repeat this operation several times.

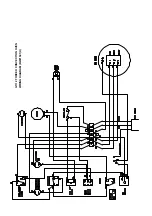

2.5.4 Multifunctional Control

Access to the control is gained upon withdrawal of the

control panel. See section 3.2.1.

The control is an SIT Electrosit 0.810.156 and

contains a number of features for effecting

adjustments. Refer to Figure 4.