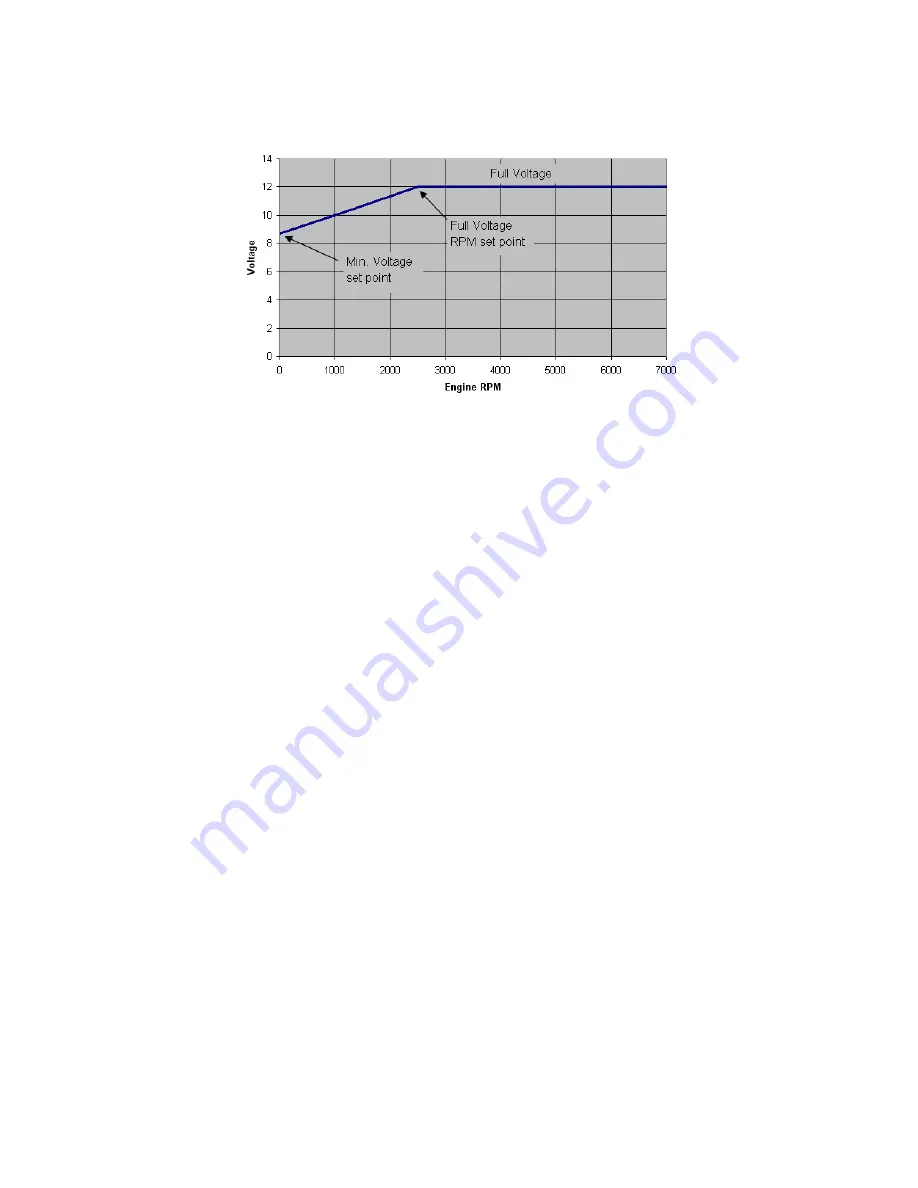

23. Once the PSC is working properly, the rpm threshold at which the pump goes to full speed can be

adjusted. To adjust the threshold, bring the engine up to the speed at which you want the fuel pump to

go to full speed. Using a ball point pin or small blunt object press the “SET TACH” button and the new

rpm will be set.

24. The initial pump voltage at idle or minimum voltage may also be adjusted by using a small screw

driver and turning the “MIN VOLTS” screw on the front of the controller. Turning the adjustment screw

counter-clockwise will decrease the initial pump voltage and clockwise will increase the initial pump

voltage. This adjustment screw has a 15-turn range.

The PSC is now ready for use. Upon pump startup, the PSC will cause the pump to go to full speed for

several seconds. After the initial several seconds, the PSC will slow the pump down, unless the engine

rpm is raised above the threshold value or the Manual Override Switch is activated. As long as the engine

rpm is above the threshold value or the Manual Override Switch is activated, the pump will run at full

speed.

If you experience problems with the PSC, the following diagnostics can be performed.

•

Using a test light, make sure positive battery power is being supplied to the PSC terminal “IGN PWR” and the “BAT+” terminal.

•

Using a test light, make sure the PSC terminal marked “GND” is connected to ground.

•

Using a test light, make sure the PSC terminal marked “OVERRIDE” is connected to ground, through the Manual Override

Switch.

With the engine running, make sure the “TACH” light is flashing. If it is not, check the tach signal wire and connections.