22

23

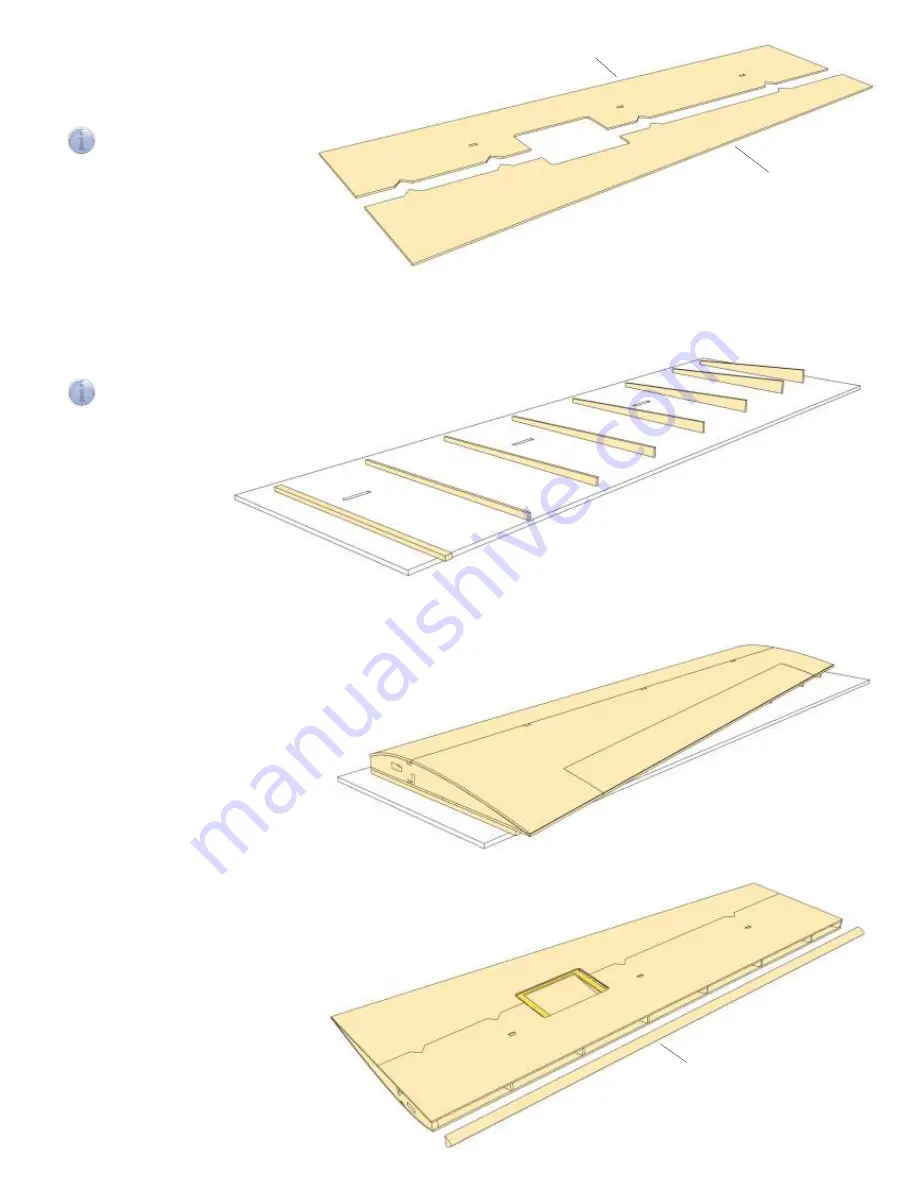

Glue together lower wing sheeting F47, F48 (L/R) and secure with tape

until dry.

Insert supports H3 to H10 into jig at rib positions.

The use of supports H3 to H10 guarantees correct amount of washout in outer wing

panel.

Note:

Picture shows arrangement for right wing panel. Turn jig upside down and

reverse order of supports for left wing panel.

F47 L/R

F48 L/R

H3

H4

H5

H6

H7

H8

H9

H10

Optional:

If the model is to be

equipped with ailerons, insert aileron

servo lead now and secure in servo bay

with tape.

24

Slightly bevel rear edge of upper wing sheeting to establish a good contact surface for gluing.

Align lower wing sheeting with tabs on main spar and place sheeting panel on spars and ribs.

Check for correct fit, then glue in place and briefly press onto a flat surface.

Remove any residual glue from inner edge

of servo frame.

At rear edge of wing secure upper an lower

wing sheeting with two strips F11 and

clamps, then place outer wing panel on

supports. Make sure front edge of wing

sheeting is flus with front end of supports.

Weigh down wing panel evenly on supports

and let dry.

F49

25

Sand sheeting material flush with front

end of ribs. Glue in place leading edge

F49 flush with upper sheeting and

secure to wing with tape.

26

27

Glue wing tip F54 to end rib and secure with pins.

Carefully sand completed outer wing panel and sand

contour of wing tip flush with upper and lower sheeting.

Then chamfer edge of wing tip.

Build up opposite wing panel accordingly.

Install servo tray F50 in wing and drill servo frame F44

with 1.5 mm.

When wing is completed, attach servo tray to wing with

screws F52.

F50

F54

F55

F53

F50

F51

F51

Optional: Installing Ailerons

28

29

Cut out aileron along engraved lines and carefully sand sheeting

material and ribs flush with spars. Sand front end of aileron flush

with F41, glue aileron leading edge F55 (3 mm balsa) to F41

and bevel for sufficient control throw.

Place wing upside down on building board and replace aileron

in cut-out.

Make up control linkage from clevis F57 and threaded rod F56,

cut to length and make a Z-bend at free end. Attach control

linkage to servo arm.

Use control linkage to mark position of control horn on aileron.

Use file or razor saw to create slot for control horn F53 in

aileron and glue control horn in place.

For aileron control use servos with a maximum thickness of

8 to 10 mm.

For standard 10 mm wing servos cut to length four 20 mm

servo mounts F51 (5×3 mm spruce). Cut off bottom servo

mounting flange, align servo with servo arm centred in slot

of servo tray F50, hold in place and glue servo mounts to

tray with a drop of white glue or medium CA.

cut off

i

i

F41

Содержание LT 200 Flex

Страница 1: ...aero naut Order No 1328 00 Flex...