EN - 17

NLC_A COD: 1606.4037360_00

14.

CONTROL AND FIRST

START-UP

PREPARATION FOR COMMISSIONING

Bear in mind that a free start-up service is

offered by the Aermec Technical Service for

the unit of this series, at the request of Aermec

customers or legitimate owners and in ITALY

only. The start-up must be previously agreed on

the basis of the system implementation times.

Before the intervention all the operations

(electrical and hydraulic hook-ups, loading and

venting of the air from the system) must be

completed.

START-UP

PRELIMINARY OPERATIONS TO BE

CARRIED OUT WHEN THERE IS NO

VOLTAGE

Check:

All the safety conditions have been respected

The unit has been properly secured to the

support base

The minimum technical spaces have been

observed;

That the main power cables are of an

appropriate section, capable of supporting

the overall absorption of the unit. (see electric

data section), and that the unit has been duly

earthed.

That all the electrical connections are correctly

fixed and that all the terminals adequately

tightened.

THE FOLLOWING OPERATIONS MUST BE

CARRIED OUT WHEN THE UNIT IS LIVE.

Power up the unit by turning the main switch

to ON. The display will come on a few seconds

after the machine is powered up, check that the

operation status is at OFF (OFF BY KEYB at the

bottom of the display).

Use a tester to check that the value of the

supply voltage to the U.V.W. phases is equal to

400V ±10%, and also check that the unbalance

between the phases does not exceed 3%.

Check that the connections made by the installer

comply with the data in the documentation.

Check that the electric heater(s) of the

compressor casing are working, by measuring

the rise in the temperature in the oil sump. The

resistance(s) must operate for at least 12 hours

before the compressor start-up, and in any case

the temperature of the oil sump must be 10-

15°C higher than the room temperature.

Check and if necessary change the fan settings

in order get the correct useful static pressure

required by the system

(

Setting the fan's

number of rpm from the control panel)

.

HYDRAULIC CIRCUIT

Check that all the hydraulic connections have

been carried out correctly, that the information

on the plates have been complied with and

that a mechanical filter has been installed at

the evaporator inlet. (Mandatory component

subject to the invalidation of the warranty).

The flow switch must absolutely be installed,

and should be wired to the electrical panel,

calibrated and its intervention verified

(Obligatory component subject to the

invalidation of the warranty).

Check that the circulation pump(s) are working,

and that the water flow rate is sufficient to

close the flow switch contact.

Check the water flow rate, measuring the

difference of pressure between the evaporator

inlet and outlet, and then calculate the flow

rate with the evaporator pressure drop diagram

in the this documentation.

Make sure the flow switches are working

correctly (installation mandatory)

; closing the

cut-off valve at the heat exchanger outlet; the

block should be displayed on the unit's control

panel; finally open the valve again and rearm

the block.

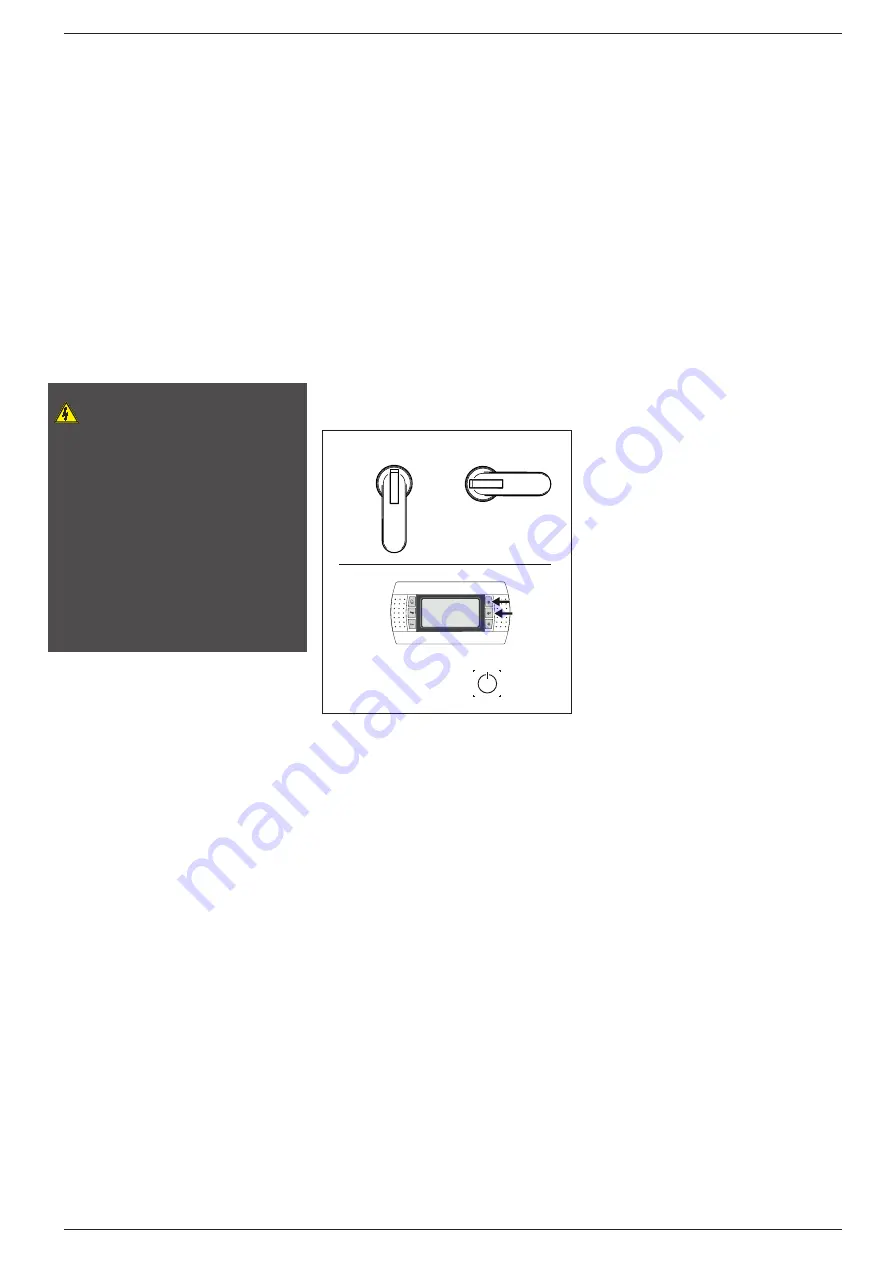

FIRST COMMISSIONING OF THE

MACHINE

ON

ON

OFF

OFF

SELECT MENÙ

ON/OFF

WITH THE MACHINE ON CHECK THE

REFRIGERANT CIRCUIT

CHECK:

•

Check that the absorption current of the

compressor is less than the maximum

indicated in the technical data table.

•

Check that in models with three-phase

supply power the noise level of the

compressor is not abnormal, symptom

of reverse rotation and, if this is the case,

invert a phase.

•

Make sure that the voltage value is within

the pre-fixed limits and that the unbalance

between the three phases (three-phase

supply power) does not go above 3%.

•

Check for refrigerant gas leaks, especially

near the pressure points of pressure

gauges, pressure transducers and pressure

switches; (vibrations during transport may

have loosened the connections).

OVERHEATING

By comparing the temperature read with a

contact thermostat placed on the compressor

intake and the temperature shown on the

low pressure gauge (saturation temperature

corresponding to the evaporation pressure). The

difference between these two temperatures

gives the overheating value. Optimum values

are between 4 and 8°C.

DISCHARGE TEMPERATURE

If the sub-cooling and overheating values are

correct, the temperature measured in the

pressing line tube at the compressor outlet

must be 30/40°C above the condensation

temperature.

CONTROL AND SAFETY DEVICES

CHECK

:

THE MANUAL RESET HIGH PRESSURE

SWITCH

That stops the compressor and generates

the respective alarm when the flow pressure

exceeds the set value. To check it is operating

correctly, close the air intake to the heat

exchanger (cooling mode), and keeping an eye

on the high pressure gauge, check it intervenes

at the calibration setting. Warning: If the switch

does not trip at the calibration value, stop the

compressor immediately and check the causes.

The reset is manual and can only take place

when the pressure drops below the differential

value. (For the set and differential values, see

the technical manual).

ANTI-FREEZE CONTROL

The anti-freeze control, which is managed by

electronic regulation and by the temperature

probe at the evaporator outlet, has the function

of preventing the formation of ice when the

water flow rate is too low. Checking it is working

correctly can be carried out by progressively

increasing the anti-freeze set-point until it

exceeds the outlet water temperature and

keeping the water temperature under control

with a high precision thermometer. Check that

the unit switches off, setting off the respective

alarm. After this operation take the anti-freeze

set-point back to its original value.