Call StormTech at

860.529.8188

or

888.892.2694

or visit our website at

www.stormtech.com

for technical and product information.

26

8.0 Outlets for Chambers

Table 9B – Maximum Outlet Flow Rate Capacities from

StormTech Manifolds

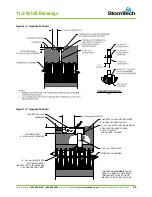

Figure 10 – Underdrain Parallel

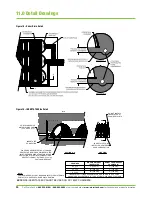

Figure 11 – Underdrain Perpendicular

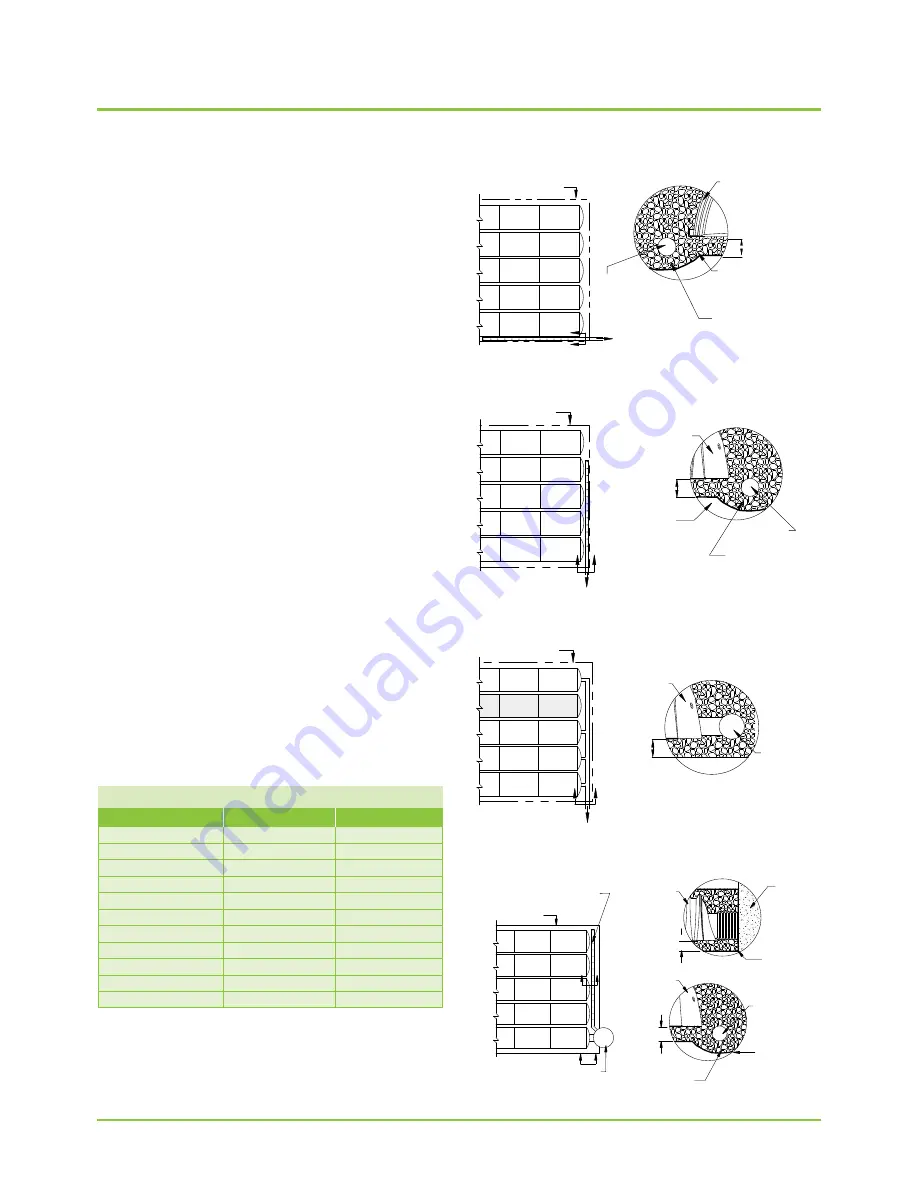

Figure 12 – Outlet Manifold

Figure 13 – Combination Outlet

OUTLET FLOW

PIPE DIA.

FLOW (CFS)

FLOW (L/S)

6” (150 mm)

0.4

11.3

8” (200 mm)

0.7

19.8

10” (250 mm)

1.0

28.3

12” (300 mm)

2.0

56.6

15” (375 mm)

2.7

76.5

18” (450 mm)

4.0

113.3

24” (600 mm)

7.0

198.2

30” (750 mm)

11.0

311.5

36” (900 mm)

16.0

453.1

42” (1050 mm)

22.0

623.0

48” (1200 mm)

28.0

792.9

8.0 OUTLETS FOR STORMTECH CHAMBER SYSTEMS

The majority of StormTech installations are detention

systems and have some type of outlet structure. An outlet

manifold is generally designed to ensure that peak flows

can be conveyed to the outlet structure.

To drain the system completely, an underdrain system is

located at or below the bottom of the foundation stone.

Some beds may be designed with a pitched base to

ensure complete drainage of the system. A grade of ½%

is usually satisfactory.

An outlet pipe may be located at a higher invert within a

bed. This allows a designed volume of water to infiltrate

while excess volumes are outlet as necessary. This is an

excellent method of recharging groundwater, replicating a

site’s pre-construction hydraulics.

Depending on the bed layout and inverts, outlet pipes

should be placed in the embedment stone along the bed’s

perimeter as shown in

Figures 10

and

11

. Solid outlet

pipes should also be used to penetrate the StormTech end

caps at the designed outlet invert as shown in

Figure 12

.

An Isolator Row should not be directly penetrated with an

outlet pipe. For systems requiring higher outlet flow rates,

a combination of connections may be utilized as shown in

Figure 13

.

In detention and retention applications the discharge

of water from the stormwater management system is

determined based on the hydrology of the area and the

hydraulic design of the system. It is the design engineer’s

responsibility to design an outlet system that meets

their hydraulic objectives while following local laws and

regulations.

STORMTECH

CHAMBER

PERFOR ATED

UNDERDRAIN PIPE

ADS 601 NON-WOVEN

GEOTEXTILE (OR EQUAL)

STONE BEDDING

UNDER DRAINAGE

PIPE (PER DESIGN)

STONE BASE

BENEATH

CHAMBER

SECTION A_A

BED PERIMETER

TO OUTLET

CONTROL

STRUCTURE

A

A

BED PERIMETER

TO OUTLET CONTROL

STRUCTURE

B

B

PERFORATED

UNDERDRAIN PIPE

ADS 601

NON-WOVEN

GEOTEXTILE

(OR EQUAL)

STONE BEDDING

UNDER DRAINAGE

PIPE (PER DESIGN)

STONE BASE

BENEATH

CHAMBER

SECTION B_B

STORMTECH

CHAMBER

STORMTECH

CHAMBER

MANIFOLD

OUTLET

PIPING

STONE

BASE

BENEATH

CHAMBER

SECTION C_C

BED PERIMETER

ISOLATOR ROW

TO OUTLET CONTROL

STRUCTURE

C

C

STORMTECH

CHAMBER

STORMTECH

CHAMBER

PERFORATED

UNDERDRAIN PIPE

AASHTO M288

CLASS 2

NON-WOVEN

GEOTEXTILE

STONE BEDDING

UNDER DRAINAGE

PIPE (PER DESIGN)

SECTION B_B

SECTION A_A

FOUNDATION

STONE BENEATH

CHAMBER

FOUNDATION

STONE

BENEATH

CHAMBER

ADS 601

NON-WOVEN

GEOTEXTILE

(OR EQUAL)

OUTLET

CONTROL

STRUCTURE

BED PERIMETER

OUTLET CONTROL STRUCTURE

PER ENIGNEER'S DESIGN

NUMBER AND SIZE OF UNDER-

DRAINS PER ENGINEER DESIGN

B

B

A

A

Содержание StormTech DC-780

Страница 2: ...An company TOOL 2 0 DESIGN ...

Страница 39: ......