- 5 -

3. Product Overview

3.1 Introduction

X203H is defined as our new 20’W model in ACER V series which will be the ACER project in

Qisda. X203H is defined as 20’W LCD Monitor supports 1600(H) x 900(V) resolution with DPMS

(Display Power Management System) and ACER eColor function. There are double input types,

D-sub, and DVI. X203H adopts SEC LTM200KT03 and LGD LM200WD1-TLC1. V203H has

included 1W+1W speaker.X203H also support ACM 10000:1.

The features summary is shown as below,

*All panel spec. in Q201 definition depends on the variance of panel source.

*All spec. of monitor need to warm up at least 1hr.

* To test the “Contrast Ratio” and “Luminance” functions, the color status must be “User preset”

mode.

* 1. “Contrast Ratio”: Set “brightness” at 100, and “contrast” at 50.

* 2. “Luminance”: Set “brightness” at 100, and “contrast” at 100.

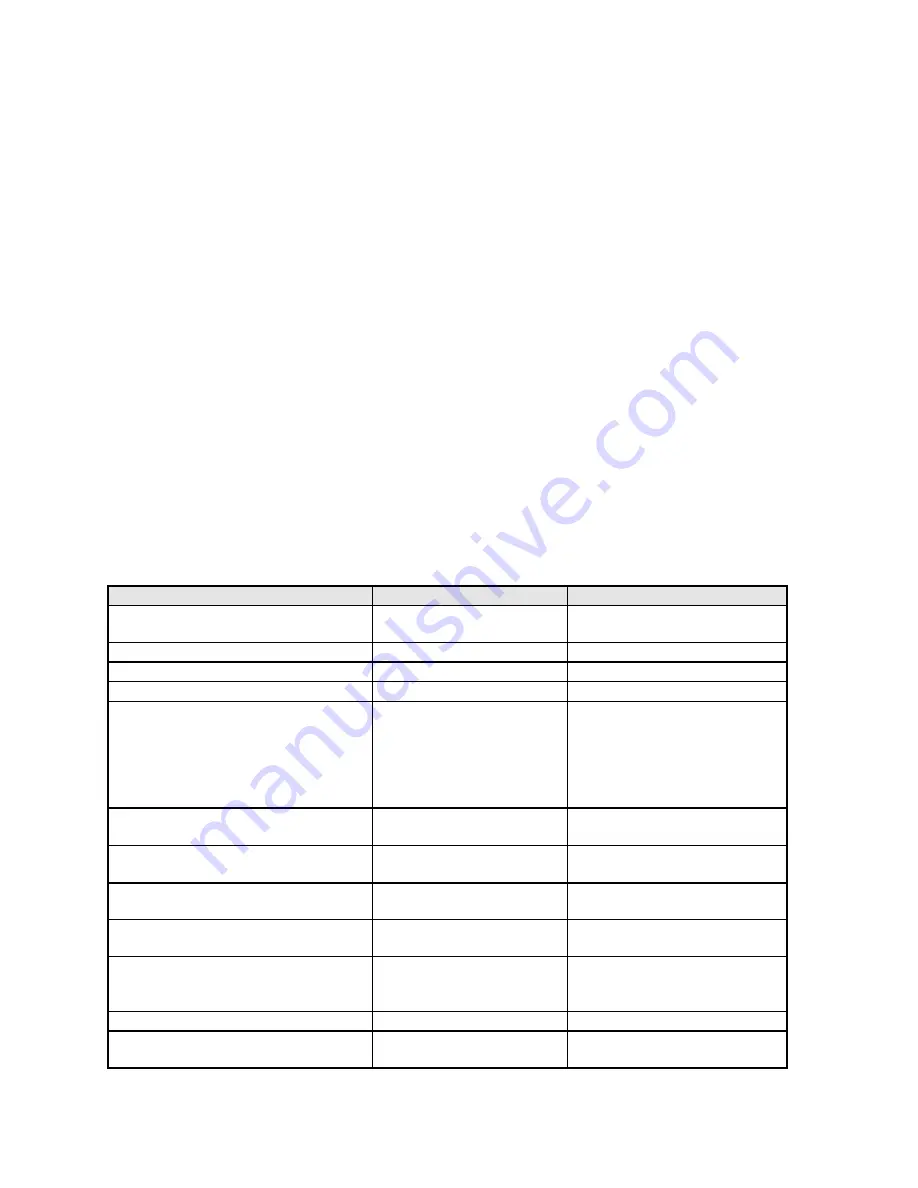

Feature items

Specifications

Remark

Panel supplier & module name

SEC LTM200KT03

LGD LM200WD1-TLC1

TN, Normally white

Screen diagonal

20W”

Display Format

1600(H) x 900 (V)

Panel Display information

Pixel Pitch

276.8 um x 276.8um

per one triad

Viewing Angle (@ Contrast Ratio

>= 10)

SEC LTM200KT03

R/L:160 degrees (typ)

U/D: 160 degrees (typ)

LGD LM200WD1-TLC1

R/L:170 degrees (typ)

U/D: 160 degrees (typ)

Analog interface with Scaling

supported

Yes

With 15-pin D-sub connector

HDMI interface with Scaling

supported

No

Only For 1A2H model

Panel native resolution supported

1600 (H) x 900

(V)@60Hz

Number of Display Colors

supported

16.7 Millions

RGB 6-bit +Hi-FRC

Contrast Ratio

1000:1 (typ.), 700:1(min)

Test Condition: Set Contrast

at 50, Brightness at 100,

Color at User preset

1. ACM

10000:1

2. Luminance

250 cd/m

2

(typ.),200

cd/m

2

(min)

Test Condition: Set Contrast

at 50, Brightness at 100,

Содержание X203H

Страница 21: ... 21 4 Disassembly Assembly 4 1 Exploded View 1 2 3 18 9 8 14 4 5 19 6 21 20 13 12 17 11 7 15 10 16 22 23 24 25 ...

Страница 22: ... 22 ...

Страница 33: ... 33 13 Get off the panel from the bezel 14 Get off the big tap from the tape 15 Disassemble the control board ...

Страница 42: ... 42 5 3 EDID Upgrade Procedure Step 1 Run the program Q EDID V012 exe when the UI popped up ...

Страница 43: ... 43 Note If VGA choose 128bytes and DVI choose 128bytes Step 2 Click Open File and select VGA or DVI EDID file ...

Страница 45: ... 45 Step 5 If read EDID is successful it shows Read EDID OK ...

Страница 46: ... 46 5 4 OSD Operation Guide ...

Страница 47: ... 47 ...

Страница 48: ... 48 ...

Страница 49: ... 49 ...

Страница 50: ... 50 ...

Страница 53: ... 53 6 1 3 Check Scalar ...

Страница 55: ... 55 6 1 5 Power Board no work troubleshooting ...

Страница 56: ... 56 6 1 6 Audio Function ...

Страница 66: ... 66 Appendix 2 Physical Dimension Front View and Side view Fig 1 Physical Dimension Front View and Side view ...

Страница 67: ... 67 Fig 2 Appearance Description ...

Страница 68: ... 68 Appendix 3 Interface Board ...

Страница 69: ... 69 ...

Страница 70: ... 70 ...