EN

-

14

7 Operation

ABICOOLER 1300

7 Operation

► Switch the device on and off with the ON/OFF switch.

7.1 Prior to initial commissioning and after a longer standstill

1

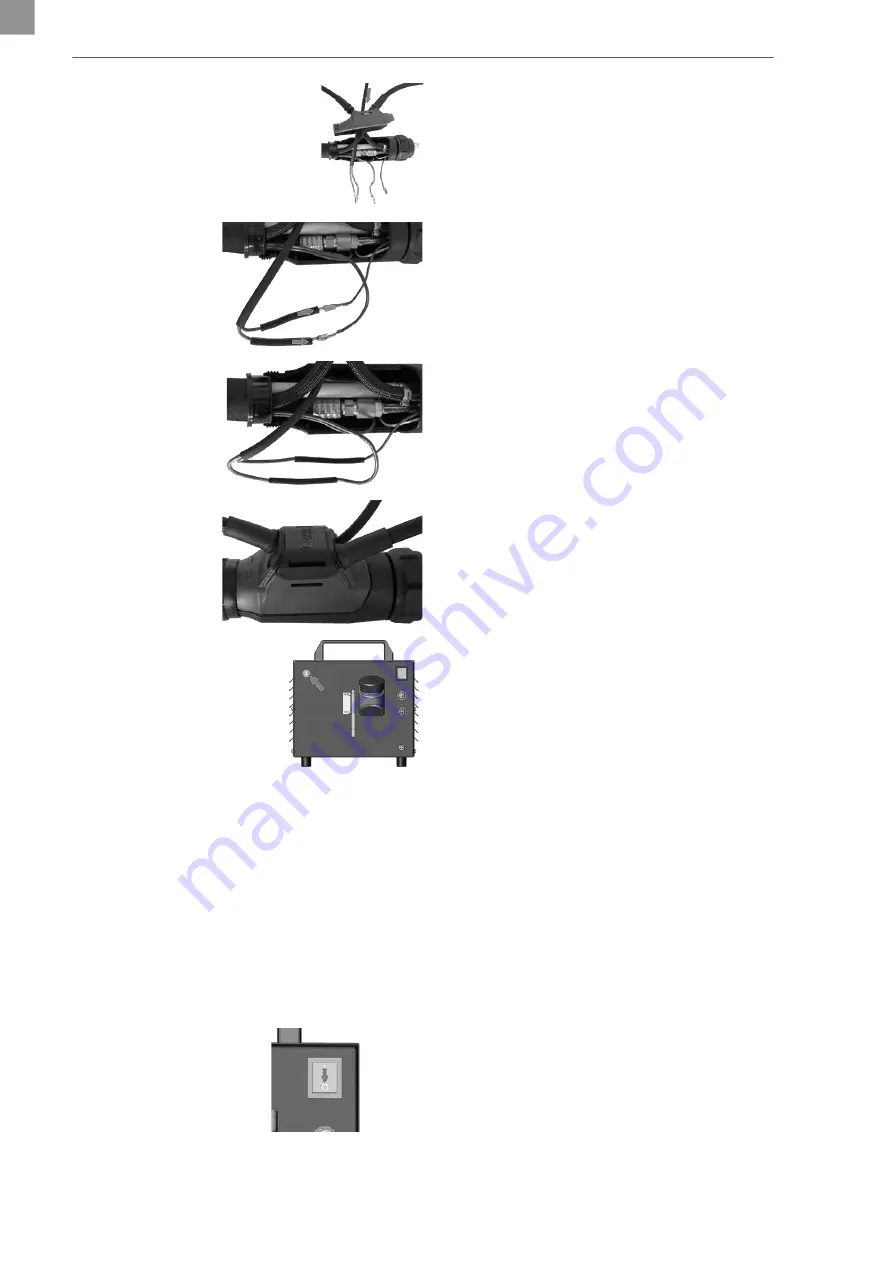

Bleed the device and cable assembly.

6.2.1 Bleed the device on page EN

6.2.2 Bleeding the cable assembly on page EN

2

Check the tightness of the coolant connections.

8 Decommissioning

► Observe the documentation for the welding components.

4

Guide the flow control with the line ends through the opening.

5

Pull the heat-shrinking tube over both line ends and connect the

button line to the flow control.

6

Warm the heat-shrinking tube and insulate the connection

point.

7

Place the lines in the connection housing and assemble the

connection housing.

8

Insert the flow control's plug in the connection on the device.

1

Switch off the device.

2

Pull out the mains plug to disconnect from the power supply.