Date: 2021-01-13

Version: 1.2

Overhaul instructions

Central lubrication unit

Removing

Page 16 of 50

•

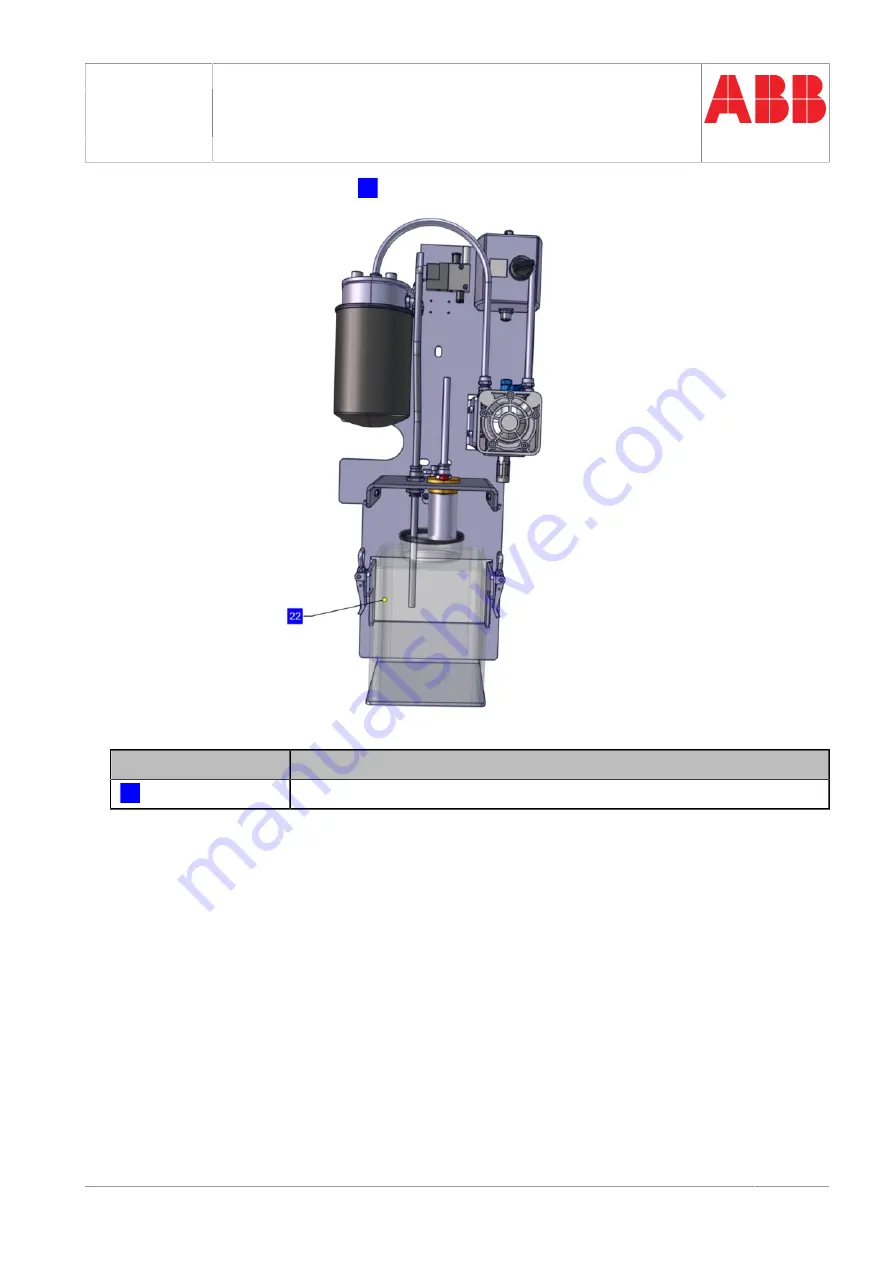

Remove the square container (

22

) with the Mesamoll to be replaced.

Figure 2: Removing the container

Item number

Designation

(

22

)

Square container

© 2021 ABB Automation GmbH |

en