10.

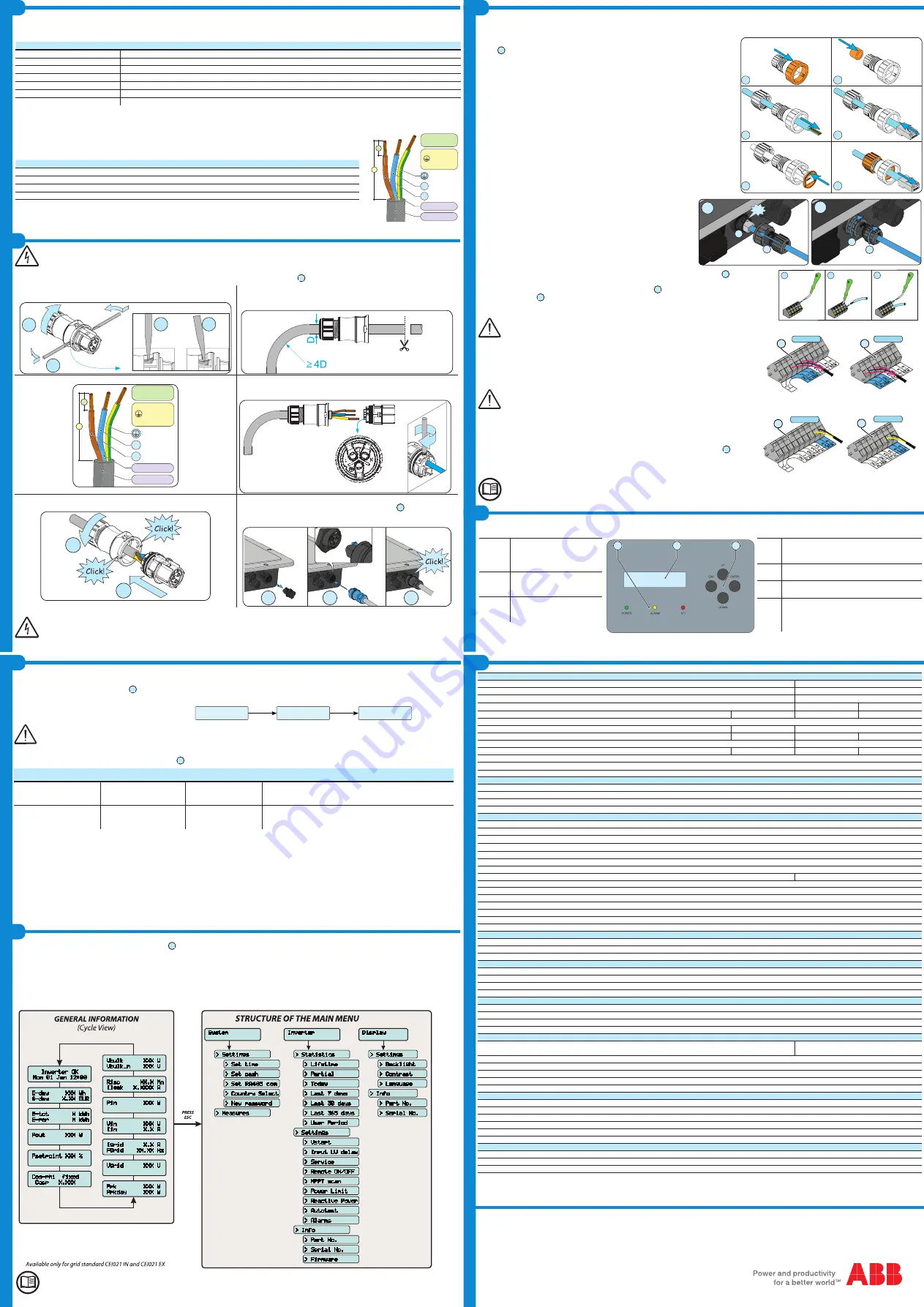

Connection of the communication and control signals

12.

Commissioning

11.

Instruments

UNO-2.0_3.0_3.6_4.2-TL-OUTD-Quick Installation Guide EN-RevA

EFFECTIVE 2015-07-22

© Copyright 2015 ABB. All Rights Reserved.

Specifications subject to change without notice.

8.

Line cable and protection devices

9.

Output connection (AC)

13.

Structure of the display menu

14.

Characteristics and T

echnical Data

Contact us

www.abb.com/solarinverters

Connection of the communication signals (RS485 line)

On the inverter there is a RS485 communication line for connecting the inverter to monitoring devices. The line may also be used to store settings with the

dedicated advanced configuration software.

The connection of the serial communication cable must be made to the specific RS485 con

-

nector

14

present on the lower side of the inverter. An RJ45 connector must be installed on the

cable and the connector in its turn must be placed in the specific corresponding part (provided)

which allows the inverter to maintain its level of IP protection.

1. Install the blocking ring nut on the connector body

2. Install the gasket inside the connector body

3. Feed the cable through the holding ring nut and the connector body

4. Install the RJ45 connector on the cable and push it inside the connector body until it fits into

place.

5. Insert the gasket through the RJ45 connector and position it seated on the connector body

6. Extract the cable from the corresponding part just enough to enable connection with the

connector on the inverter.

At the end of the cable preparation stage, it is possible to proceed with connecting the commu-

nication line to the inverter.

1a. Install the cable on the RS485 connector on the inverter.

1b. Slide the corresponding part on to the cable until it is snug with the RS485

connector of the inverter. The insertion of the corresponding part is guided by

reference points which enable its correct positioning.

2a. Turn the fixing ring nut until the two connectors are blocked and check the

correctness of the installation.

2b. Turn the holding ring nut to a tightening torque of 0.6÷0.8Nm

Connection of the control signals

The connection of the control signals must be done on the specific signal terminal block

13

inside the

inverter using a flat screwdriver as shown in the figure:

Each cable which must be connected to a signal terminal block

13

must pass through one of the three

service cable glands

20

. Each cable gland (M20) can take a cable with diameter from 7 mm to 13 mm.

A gasket with two holes to insert into the cable gland which enables two separate cables of a maximum

diameter of 5 mm to be accommodated is available.

Warning! To ensure environmental protection rating IP65 it is necessary to tighten the cable gland with a torque of 2.5Nm

Use of the configurable relay

The inverter has a relay, the activation of which is configurable; it is possible to connect external

devices which, depending on the mode selected on the dedicated menu (Inverter > Settings > Alarms

> Set alarm type) can, for example, signal malfunctions. The operating modes that can be set are:

Production, Alarm, Alarm Configurable, Crepuscular, Alarm Configurable Latch, Alarm Configurable

ext, GoGo relay (Auto), GoGo relay (Slave).

The ALARM contact can only be used with systems which guarantee at least additional safety insulation (additional insulation in relation

to the input DC voltage)

Use of the remote ON/OFF signal

The connection and disconnection of the inverter to and from the grid can be controlled through an

external control. If the remote control function is operating, besides being dictated by the presence of

the normal parameters that allow the inverter to connect to the grid, start-up of the inverter also depen-

ds on the state of the terminal

R+

compared to the terminal

R-

present on the connector

13

. When the

R+ signal is brought to the same potential as the R- signal (that is to say when a short-circuit is created

between the two connector terminals) the inverter is disconnected from the grid.

For further information regarding the configuration and use of the communication and control signals terminal block, please see the

manual

The inverter commissioning procedure is as follows:

-Close the DC disconnect switch to supply the inverter with the photovoltaic generator voltage. If the inverter is equipped with a DC disconnect switch (-S

models), turn the DC disconnect switch

16

to the ON position.

-

When the inverter is connected to the power supply, the display will show a guided configuration procedure. Press ENTER to set the following:

Inverter date and time

Grid standard and corresponding display language

Warning! The settings become fixed after 24 hours of operation of the inverter (the inverter simply has to be powered by PV generator).

-After you have set the grid standard, the message "Initializing...Please Wait” is displayed. Regardless of the input voltage value, the inverter displays various

messages and changes the behaviour of the three LEDs

06

:

INPUT VOLTAGE

DISPLAYED MESSAGE

LED STATUS

DESCRIPTION

Vin < Vstart

Waiting sun

Green = FLASHING

Yellow = OFF

Red = OFF

The input voltage is not sufficient to enable connection to the grid.

Vin > Vstart

Vac Absent

Green = FLASHING

Yellow = ON

Red = OFF

The input voltage is sufficient to enable connection to the grid: the

inverter waits for the grid voltage to be present to make the parallel

connection.

The inverter is powered SOLELY by the voltage generated by the photovoltaic generator: the current in the attachment to the grid voltage is NOT

SUFFICIENT to switch on the inverter on its own.

-With the inverter in the "Missing Grid" status, close the AC switch downstream of the inverter thus applying the grid voltage to the inverter: the inverter checks

the grid voltage, measures the insulation resistance of the photovoltaic array with respect to ground and performs other auto-diagnostic tests. During the

preliminary checks on the parallel connection with the grid, the green LED keeps flashing, the others are off.

During the check on the grid voltage and the measurement of the insulation resistance, the voltage, grid frequency and insulation resistance values

measured by the inverter are displayed. The inverter ONLY creates a parallel connection with the grid if the grid and insulation resistance parameters

fall within the ranges foreseen by current regulations.

-If the outcome of the preliminary checks on the grid parallel is positive, the inverter connects to the grid and starts to export power to the grid. The green LED

remains constantly lit while the others are off.

LEDs and BUTTONS

, in various combinations, can be used to view the status or carry out complex actions that are described more fully in the manual.

LEDs

POWER

GREEN

Lit if the inverter is

working correctly. Flashes when

checking the grid or if there is

insufficient sunlight.

LEDs

ALARM

YELLOW

The inverter has

detected an anomaly. The ano-

maly is shown on the display.

LEDs

GFI

RED

Ground fault on the DC

side of the PV generator. The

error is shown on the display.

The ABB inverters are equipped with a graphic display

07

, consisting of 2 lines of 16 characters each, which can be used to:

-View the operating status of the inverter and the statistical data

-View service messages for the operator

-View alarm and fault messages

-Change the inverter settings

During the normal operation of the inverter the display cycles through the

GENERAL INFORMATION.

This information relates to the input and output parame-

ters and the inverter identification parameters. By pressing

ENTER

it is possible to block scrolling on a screen so that it is constantly displayed.

Press

ESC

to access the main menu which is structured as follows:

> Settings

> Measures

> Set time

> Set cash

> Set RA485 com

> Country Select

> New password

Inverter

> Statistics

> Settings

> Vstart

> Input UV delay

> Service

> Info

> Part No.

> Serial No.

> Firmware

> Remote ON/OFF

> MPPT scan

> Power Limit

> Reactive Power

> Autotest

> Alarms

> Lifetime

> Partial

> Today

> Last 7 days

> Last 30 days

> Last 365 days

> User Period

Display

> Settings

> Info

> Part No.

> Serial No.

> Backlight

> Contrast

> Language

*

Inverter OK

Mon 01 Jan 12:00

E-day XXX Wh

$-day X.XX EUR

E-tot X kWh

E-par X kWh

Pout XXX W

Psetpoint XXX %

Cos-phi fixed

Cosp X.XXX

Pin XXX W

Vin XXX V

Iin X.X A

Igrid X.X A

Fgrid XX.XX Hz

Vgrid XXX V

Ppk XXX W

Ppkday XXX W

Riso XX.X M©

Ileak X.XXXX A

Vbulk XXX V

Vbulk_m XXX V

System

*

Refer to the manual for details regarding use and functions available in the menu.

Warning! Before performing any of the operations described below, ensure the AC line downstream from the inverter has been correctly

disconnected.

For the connection of the inverter to the grid you need 3 connections: ground, neutral and phase. In any case, connection of the inverter to ground is mandatory.

The connection of the grid cable to the inverter is realized through the dedicated AC output connector.

10

by undertaking the following operations:

1. Remove the head of the connector by pressing on the two holding clips

and subsequently loosen the cable gland.

2

1

1a

1b

2. Feed the cable through the connector and cut the cable to correct length

Ensure that the cable's radius of curvature is more than 4 times the diameter

of the cable

3. Prepare the cable respecting the following measurements.

N

L

Max 6 mm²

x:

8 mm

Ø10÷14mm

x

y

y:

30mm

L,N 25 mm

4. Install the single wires (phase, neutral and ground) on the head of the

connector respecting the indications printed on each of the three connection

terminals (tightening torque 0.8...1Nm)

5. Close the connector and tighten the cable gland respecting the torque

(4+1Nm) in order to guarantee the IP65 protection level

1

2

6. Remove the pre-installed protective cover from the inverter.

Insert the corresponding part in the AC output connector

10

being careful

to align the reference points (present on both connectors) which prevent

connection errors.

2

1

3

In order to maintain the inverter's level of IP protection, the corresponding part must be obligatorily installed with the connected AC cable

or the protective cover, on the AC output connector.

In addition, the connector must not be subject to tensile forces (examples: do not connect weights to the AC cable, do not leave excess

cable windings hanging, etc).

UNO-2.0-TL-OUTD(-S) UNO-3.0-TL-OUTD(-S) UNO-3.6-TL-OUTD(-S) UNO-4.2-TL-OUTD(-S)

Input

Absolute maximum input voltage (V

max,abs

)

600 V

850 V

Input start-up voltage (V

start

)

100...300 V (default 150 V)

300...600 V (default 380 V)

Operating DC input voltage range (V

dcmin

...V

dcmax

)

0.7xV

start

...580 V (min 80V)

350...820 V

Rated DC input voltage (V

dcr

)

400 V

500 V

600 V

Input DC nominal power (P

dcr

)

2200 W

3200 W

3900 W

4500 W

Number of Independent MPPT

1

DC Voltage MPPT interval (V

MPPT min

... V

MPPT max

) a P

acr

180...500 V

200...500 V

380...700 V

Maximum DC input current (I

dc max

)

12.5 A

16.0 A

11.0 A

12.5 A

Maximum return current (AC side vs. DC side)

< 5 mA

4.7 A

Maximum short circuit current (I

sc max

)

15.0 A

20.0 A

15.0 A

15.0 A

Number of DC connection pairs in input

1

DC connection type

Quick fit PV connector

(1)

Type of photovoltaic panels that can be connected at input according to IEC 61730

Class A

Input protection

Reverse Polarity Protection

Yes, from current limited source

Input overvoltage protection - Varistors

Yes

Insulation check

Complying with the local standard

Characteristics of DC disconnect switch (version with DC disconnect switch)

600 V, 25A

1000 V, 16A

Output

AC grid connection type

Single phase

Nominal AC output power (P

acr@cosφ=1

)

2000 W

3000 W

3600 W

4200 W

Maximum AC output power (P

ac max@cosφ=1

)

2000 W

3000 W

3600 W

4200 W

Maximum apparent power (S

max

)

2000 VA

3000 VA

3600 VA

4200 VA

Nominal AC output voltage (V

acr

)

230 V

Output AC voltage range (V

acmin

...V

acmax

)

180...264 Vac

(2)

Maximum AC output current (I

ac max

)

10.0 A

15.0 A

16.0 A

20.0 A

Maximum fault current

18.3 A rms (20ms)

22.9 A rms (20ms)

Contribution to short-circuit current

12.0 A

17.0A

18.0A

22.0A

Inrush current

Negligible

Nominal output frequency (f

r

)

50 Hz / 60 Hz

Output frequency range (f

min

...f

max

)

47...53 / 57...63 Hz

(3)

Nominal power factor and adjustability interval

> 0.995, adj. ±0.8 with max Smax

Total current harmonic distortion

<3%

AC connections type

Female connector from panel

Output Protection

Anti-islanding protection

Complying with the local regulations

Maximum AC overcurrent protection

16.0 A

20.0 A

20.0 A

25.0 A

Output overvoltage protection - Varistor

2 (L - N / L - PE)

Operating Performance

Maximum efficiency (η

max

)

97.3%

98.4%

Weighted efficiency (EURO/CEC)

96% / -

97.5% / -

Power supply threshold

8.0 W

Night-time consumption

< 0.1W

Communication

Remote monitoring

VSN300 Wifi Logger Card (opt.), VSN700 Data Logger (opt.)

Wireless local monitoring

VSN300 Wifi Logger Card (opt.)

User interface

Display LCD with 16 characters x 2 lines

Wired Local Monitoring

PVI-USB-RS232_485 (opt.)

Environmental

Ambient temperature

-25...+60°C / -13...140°F with derating above

45°C / 113°F

-20...+60°C / -4...140°F with derating above

45°C / 113°F

Relative Humidity

0...100% condensing

Typical noise emission pressure

50 dB(A) @ 1 m

Maximum operating altitude without derating

2000 m / 6560 ft

External environment pollution rating

3

Environmental class

Outdoor

Physical

Degree of environmental protection

IP 65

Cooling system

Natural

Dimensions (H x W x D)

553mm x 418mm x 175mm / 21.8” x 16.5” x 6.9”

Weight

12 kg / 26.5 lb

Assembly system

Wall bracket

Overvoltage rating compliant with IEC 62109-1

II (DC input) III (AC output)

Safety

Insulation level

Without insulation transformer (TL)

Marking

CE (50Hz only)

Safety class

I

1. Refer to the document “String inverter – Product Manual appendix” available at www.abb.com/solarinverters to know the brand and the model of the quick fit connector

2. The output voltage range may vary according to the grid standard of the country of installation

3. The output frequency range may vary according to the grid standard of the country of installation

Note. Features not specifically mentioned in this data sheet are not included in the product

N

L

Max 6 mm²

x:

8 mm

Ø10÷14mm

x

y

y:

30mm

L,N 25 mm

08

07

06

ESC

It is used to access the main menu in order to go

back to the previous menu or to go back to the

previous digit to be edited.

UP

It is used to scroll up the menu options or to shift

the numerical scale in ascending order.

DOWN

It is used to scroll down the menu options or to

shift the numerical scale in descending order.

ENTER

It can be used to confirm an action, to access

the main menu or the submenu for the selected

option (indicated by the > symbol) or to switch to

the next digit to edit.

1

2

3

4

5

6

1

2

2a

2b

0.6÷0.8Nm

Click

1a

1b

1

2

2a

2b

0.6÷0.8Nm

Click

1a

1b

WIN

D

13

UNO-2.0/3.0

13

UNO-3.6/4.2

WIN

D

13

UNO-2.0/3.0

13

UNO-3.6/4.2

Config. Wizard

ENTER to START

Time hh:mm

Date DD MMM YYYY

GRID=Xxxxxxxx

Lang=Xxxxxxxx

ENTER

ENTER

Load protection breaker (AC disconnect switch) and line cable sizing

To protect the inverter AC connection line, it is recommended to install a device to protect against maximum current and leakage to ground, with the following

characteristics:

UNO-2.0-TL-OUTD

UNO-3.0-TL-OUTD

UNO-3.6-TL-OUTD

UNO-4.2-TL-OUTD

Type

Automatic circuit breaker with differential thermal-magnetic protection

Nominal voltage

230 V AC

Nominal current

16 A

20 A

20 A

25 A

Magnetic protection characteristic

B/C

Number of poles

2

Differential protection type

A/AC

Differential sensitivity

300 mA

ABB states that ABB high frequency transformerless inverters are not such in terms of their construction to input continuous ground fault current and therefore it

is not required that the differential installed downstream of the inverter is of type B in accordance with IEC 60755/A 2.

Characteristics and sizing of the line cable

The cable to be used must be tripolar. The cross-section of the AC line conductor must be sized in order to prevent unwanted

disconnections of the inverter from the grid due to high impedance of the line which connects the inverter to the power supply.

Line conductor cross section

Line conductor maximum length (m.)

PVI-2.0-TL-OUTD

PVI-3.0-TL-OUTD PVI-3.6-TL-OUTD PVI-4.2-TL-OUTD

1.5 mm²

10 m

6 m

5 m

4 m

2.5 mm²

15 m

11 m

10 m

8 m

4 mm²

25 m

19 m

16 m

13 m

6 mm²

38 m

29 m

24 m

20 m

The values are calculated in nominal power conditions, considering:

1. a power loss of not more than 1% along the line. 2. use of copper cable, with HEPR rubber insulation and positioned in

open air

a

b

c