1ZSE 5492-156 en, Rev. 4

|

User's manual UBB

5

Operation

WARNING

The handcrank must not be inserted during electrical

operation.

WARNING

If the tap-changer is not in the exact position and the

handcrank is pulled out, the motor-drive mechanism

will start and go to the exact position if the power

supply is on.

WARNING

If a failure in power supply occurs during operation,

the operation will be completed when the power

returns.

– The position indicator shows the actual tap-position.

– The draghands show the max. and min. tap-position

between which the tap-changer has been working since

last resetting.

–

For BUE:

The tap-change in progress indicator shows

POSITION in service position, RAISE when operating in

a raise operation and LOWER when operating in a lower

operation.

–

For BUL:

The tap-change in progress indicator shows

RED during operation and WHITE when the tap-changer is

in service position.

– For resetting of the emergency stop turn the knob

clockwise.

– The LOCAL/REMOTE switch. In position LOCAL the tap-

changer can be operated by the RAISE/LOWER switch. In

position LOCAL remote operation is rendered impossible.

In position REMOTE the tap-changer is operated from the

control room or by a voltage regulator. Local operation is

not possible in remote position.

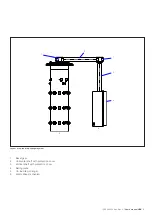

– In case of a failure in power supply for the motor-drive

mechanism, it is possible to handcrank the tap-changer.

Put the handcrank on the shaft. Make sure it has entered

the slot in the shaft. Crank in the desired direction as per

the information plate above the shaft. The number of turns

for one step is also shown on the rating plate. When the

handcrank is inserted all electrical operations are rendered

impossible. Continue cranking until the tap-changer in

progress indicator shows POSITION for BUE or white

colour for BUL.

– Thermostat for extra heater (option). We recommend a

setting at +5 °C.

– Hygrostat for extra heater (option). We recommend a

setting at approximately 60 %.

– Outlet (option) with earth fault protector.

Normally the tap-changer is controlled by a voltage regulator

and no manual operation of the tap-changer and the motor-

drive mechanism is needed.

Maintenance schedule

CAUTION

To maintain the high reliability of the tap-changer it is

important that the inspections and the overhauls be

carried out at the interval stated on the rating plate.

CAUTION

If the frequency of operations is very low and the tap-

changer is filled with degassed oil after commissioning

or overhaul, the gas cushion should be restored one

month after filling. The absence of a gas cushion

means a risk for a false trip of the pressure relay. See

Restoring the gas cushion.

Maintenance of the tap-changer consists of three major steps:

– Inspection to be carried out by site personnel once a year

(see below)

– Overhaul to be carried out by a specialist at intervals stated

on the rating plate

– Contact replacement to be carried out by a specialist. The

possible need for replacement is decided during overhaul.

A specialist is a service engineer from ABB or an authorized

person trained by ABB for maintenance work on UB tap-

changers.