Videographic Recorders

SM1000 and SM2000

2 Math Configuration

IM/SM2000ADV

Issue 7

17

Mass Flow – Derived density correction

This method uses a preset table of temperature and density

values to define the correction, which is calculated as follows:

Qmd = Qc x density correction

Mass Flow – Measured Density Correction

Qmm = Qc x input from density meter.

Where a3 is the input from an external density meter.

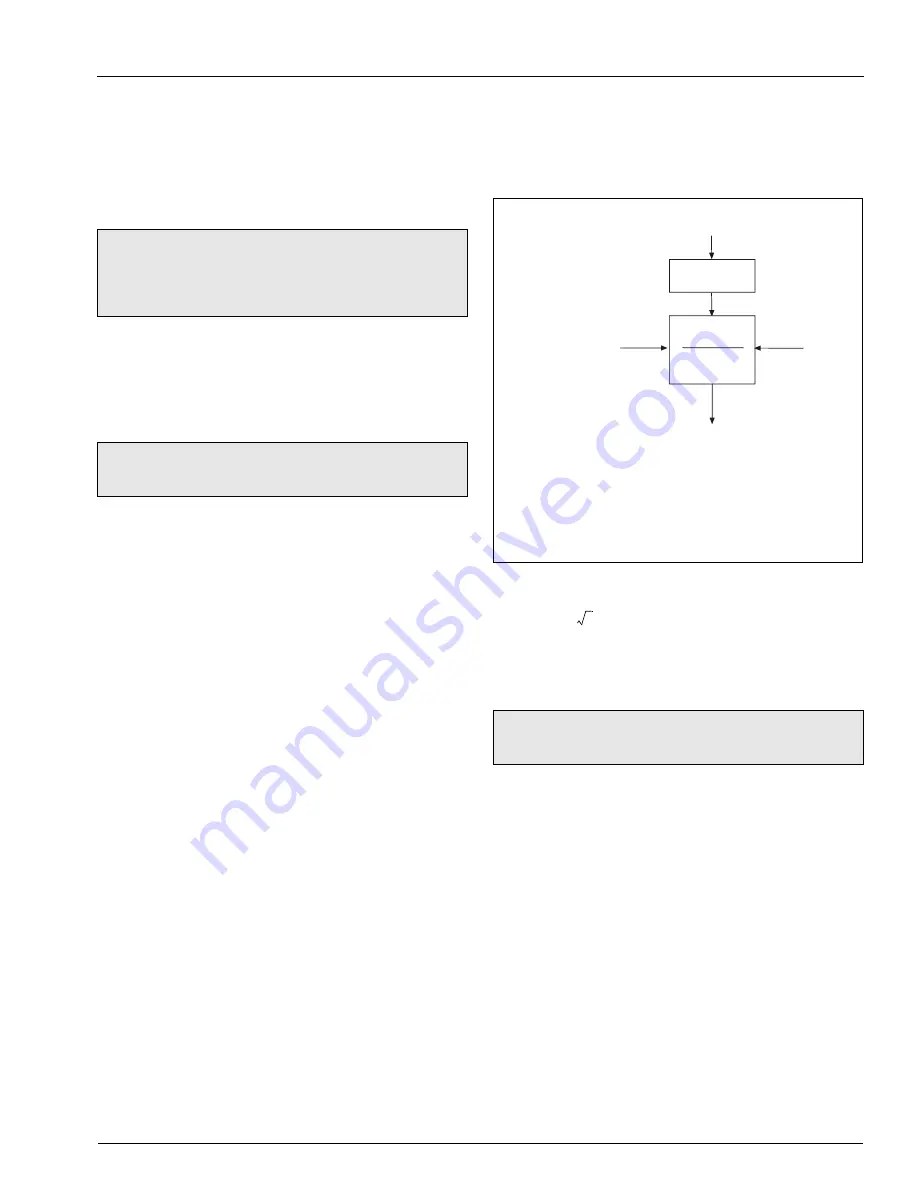

2.10.2 Ideal Gas Flow

Gas flow is usually measured using a differential pressure device

across orifice plates and wedges.

Corrections can be applied to compensate for variations in

temperature and pressure – see Fig. 2.13.

Where

, the square root extraction and scaling can be

achieved on the DP device or on the input set up of the recorder.

Let m1 = constant 1 x a3

Qc = m2 = a1 x constant2 x a2/m1

Note.

Input a3 is the actual product temperature input (as

a2 in previous examples) but with the density correction

applied using a custom linearizer – see Section 4.9.1 of the

User Guide (IM/SM1000 or IM/SM2000).

Note.

With all of the above calculations the engineering

range should allow for the extremes of all the input variables.

m3

a1

a3

scaling factor

×

×

m2

-----------------------------------------------------------

=

m3

a1

a3 m2

⁄

×

m2

-------------------------------

=

Fig. 2.13 Temperature and Pressure Compensation

Note.

The engineering range should allow for the extremes

of all the input variables.

Q

P

ref

x

T

A

x Q

T

ref

x P

A

Q

c

= Corrected Volumetric Flow

Ideal Gas Flow

P

A

T

A

Q

=

Volumetric uncorrected flow

T

ref

=

Reference temperature in K or ºR

T

A

=

Actual temperature in K or ºR

P

ref

=

Reference pressure in Absolute

P

A

=

Actual pressure in Absolute

Q

K h

=