2600T Series |

OI/JDF200-EN Rev. E 13

7 Operation

8 7 Operation

8.1 7.1 Configuration of the field indicator using the

optional integral LCD with keypad (menu-controlled)

The integral LCD is connected on the field indicator electronic

board. It can be used to visualize the process measured

variables as well as to configure the display.

In addition, diagnostic information is provided. To access the

functionality of the LCD an activation procedure needs to be

carried out. The keypad activation procedure is the same for

the TTG (Trough The Glass) version and the conventional LCD.

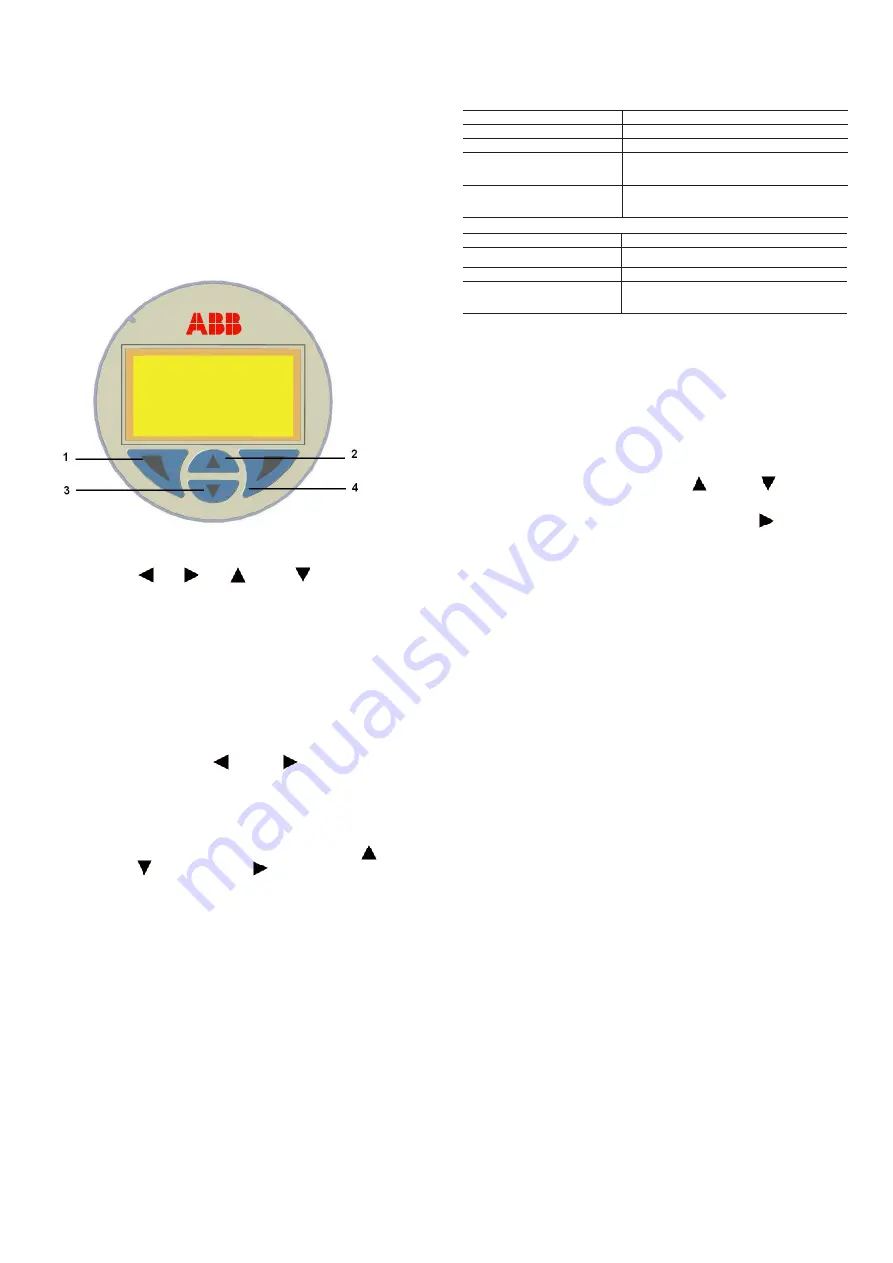

Figure 8: Display keypad

The keys (1)

, (4)

, (2)

and (3)

are available for the

menu-controlled configuration.

— The menu / submenu name is displayed above in the LCD

display.

— The number/line of the currently selected menu item is

displayed in the upper right of the LCD display.

— A scroll bar is located on the right edge of the LCD

display which shows the relative position of the currently

selected menu item within the menu.

— Both of the keys (1)

and (4)

can have various

functions.

The meaning of these buttons is displayed below in the

LCD display above the respective button.

— You can browse through the menu or select a number

within a parameter value using both keys (2)

and (3)

. The button (4)

selects the desired menu

item.

Button (1) functionalities

Meaning

Exit

Exit menu

Back

Back one submenu

Cancel

Exit without saving the selected parameter

value

Next

Select next position for entering numerical val-

ues or letters

Button (4) functionalities

Meaning

Select

Select submenu/parameter

Edit

Edit parameter

Ok

Save selected parameter and display stored

parameter value

8.2 7.2 Conventional LCD (L1 option)

Gain access to the display by unscrewing the windowed cover.

Please observe the Hazardous area prescription before

proceeding with the cover removal. For activation, see

instructions below.

8.3 7.3 LCD menu structure

The LCD menu is divided in the following sections which can

be selected by acting on the keys (2)

and (3)

, once on

the display the desired sub-menu icon will be visualized,

confirm your selection with the [SELECT] key (4)

.

Follow the instruction on the screen to perform the

configuration of the different parameters.

Содержание JDF200

Страница 15: ...2600T Series OI JDF200 EN Rev E 15 7 Operation 8 3 1 7 3 1 Easy...

Страница 16: ...16 OI JDF200 EN Rev E 2600T Series 7 Operation...

Страница 17: ...2600T Series OI JDF200 EN Rev E 17 7 Operation...

Страница 18: ...18 OI JDF200 EN Rev E 2600T Series 7 Operation 8 3 2 7 3 2 Device...

Страница 19: ...2600T Series OI JDF200 EN Rev E 19 7 Operation 8 3 3 7 3 3 Process...

Страница 20: ...20 OI JDF200 EN Rev E 2600T Series 7 Operation 8 3 4 7 3 4 8 3 5 7 3 5 Device 8 3 6 7 3 6...

Страница 33: ...2600T Series OI JDF200 EN Rev E 33...