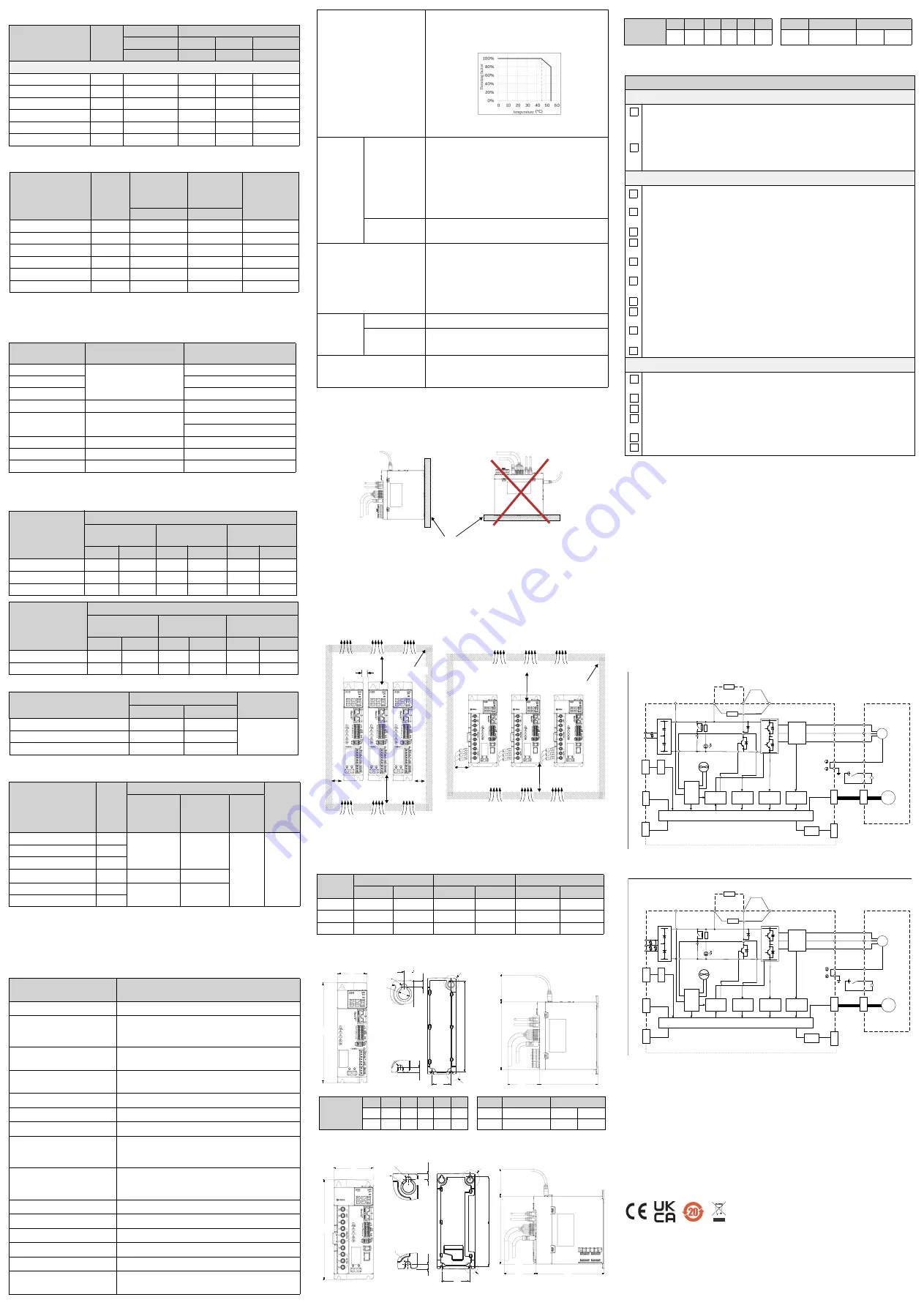

2.5 Technical data

Fuse

For detailed in

formation on cables, connectors, circuit breakers, braking

resistors, filters, Ferrite ring an

d fans,

please refer to chapter

3.6

Accessories

in

the E530-EC Servo system user manual (3AXD50001018672 [EN]).

2.6 Drive and motor configuration table

2.7 Cable specifications

Terminal data for power cables

Terminal data for the control cables

Terminal data for motor and encoder

For the technical data and speed torque curve of the motor, please refer to

chapter

3.6 Accessories

in the E530-EC Servo system user manual

(3AXD50001018672 [EN]).

3. Installing the Drive

3.1 Environmental standards

1)

For 2kW drive with 1-phase 220V input, the rated output of motor torque is

derated to 80%.

3.2 Installing oriental

E530 EtherCAT variant servo drive only supports vertical mounting. Improper

installation orientation may cause overheat and damage to the drive.

3.3 Installing clearance

When installing the drive vertically, the thermal dissipation minimum space

requirement for is shown as below. Different frame sizes have different free

space requirement. Frame sizes F2 and F3 should have a space of more than

10mm reserved on both sides of the drive, and a space of more than 100mm

above and below the drive.

F2 and F3 support compact installation, but the rated load should be reduced to

80% in this case

.

For frame size F4, a space of more than 40 mm should be reserved on the left

side (connection requirements), and a space of more than 100 mm above and

below the drive

.

3.4 Drive weight

3.5 Drill holes and outline dimensions

F2, F3

Note:

For F2, there is no a hole in the bottom left corner of the Front view.

F4

4. Basic Inspection

5. Main circuit wiring

Before wiring the servo drive, perform an insulation check on the power cable

according to safety regulations.

The main circuit of E530 EtherCAT variant servo drive is shown in the figure

below, which consists of three parts: AC power input, motor power output and

external brake resistor.

AC power input:

•

F2/F3:1-phase 220V input,only connect L1/L2,

•

F4:1-phase or 3-phase 220V input,1-phase input connect any two of L1/

L2/L3,2kW 1-phase input derating to 80%.

For detailed information on the definition of AC input terminals, definition of

drive port voltage level, wire diameter specifications of power cables, and

terminal selection of power cables, see chapter

5.3 Main Circuit Wiring

in the

E530-EC Servo system user manual (3AXD50001018672 [EN]).

6. Control diagrams

200W~1kW: 1-phase 220V input

1. * For 200W/400W, without integrated braking resistor and without fan.

2. For 750W/1kW, with integrated braking resistor and with fan.

1.5kW/2kW:1-phase or 3-phase 220V input, with integrated

braking resistor and with fan

7. Commissioning

For commissioning procedure,

see the chapter

Tuning

,

Control panel,

and

section

2.7 Quick installation and commissioning flowchart

in

E530-EC Servo

system user manual (3AXD50001018672 [EN]).

8.

Fault tracing

For detailed information on servo drive faults, alarms, see the chapter

Fault

tracking

in

E530-EC Servo system user manual (3AXD50001018672 [EN]).

9.

Markings

A CE mark is attached to the drive to verify that the unit follows the provisions

of the European Low Voltage, EMC, RoHS and WEEE Directives. Applicable

certification marks are displayed on the type label of the drive.

For more detailed information, see the section

3.8 CE marking

in the E530-EC

Servo system user manual (3AXD50001018672 [EN]).

10

Disclaimers

For more detailed information of disclaimers, see the section

3.12 Disclaimers

in

the E530-EC Servo system user manual (3AXD50001018672 [EN]).

Type

Frame

size

Input rating

Output rating

I

1N

I

2N

I

2max

P

N

A

A

A

kW

200W~1kW, 1-phase, U

N

=200...240V; 1.5kW/2kW, 1 or 3-phase, U

N

=200...240V

E530-EC0S-0KW2-1

F2

2.5

1.50

4.50

0.20

E530-EC0S-0KW4-1

F2

4.7

2.90

8.70

0.40

E530-EC0S-0KW8-1

F3

8.5

5.00

15.00

0.75

E530-EC0S-1KW0-1

F3

10.0

5.35

16.05

1.00

E530-EC0S-1KW5-2

F4

6.4

7.60

22.80

1.50

E530-EC0S-2KW0-2

F4

8.0

10.10

30.30

2.00

Drive type

Frame

size

Input current

RMS

Minimum

short circuit

current

Bussmann

type

A

kA

E530-EC0S-0KW2-1

F2

2.5

5

C10G10

E530-EC0S-0KW4-1

F2

4.7

5

C10G10

E530-EC0S-0KW8-1

F3

8.5

5

C10G20

E530-EC0S-1KW0-1

F3

10.0

5

C10G20

E530-EC0S-1KW5-2

F4

6.4

5

C10G25

E530-EC0S-2KW0-2

F4

8.0

5

C10G25

Rated power

E530 EtherCAT variant

servo drive type

DSM motor type

0.05 kW

E530-EC0S-0KW2-1

DSM04L-0KWA-302-XXXX0

0.1 kW

DSM04L-0KW1-302-XXXX0

0.2 kW

DSM06L-0KW2-302-XXXX0

0.4 kW

E530-EC0S-0KW4-1

DSM06L-0KW4-302-XXXX0

0.75 kW

E530-EC0S-0KW8-1

DSM08L-0KW8-302-XXXX0

DSM08M-0KW8-302-XXXX0

1 kW

E530-EC0S-1KW0-1

DSM13M-1KW0-202-XXXX0

1.5 kW

E530-EC0S-1KW5-2

DSM13M-1KW5-202-XXXX0

2.0 kW

E530-EC0S-2KW0-2

DSM13M-2KW0-202-XXXX0

Rated power

L1, L2, L3,

P, R, C, N

terminals

Min

(solid/stranded)

Max

(solid/stranded)

Tightening

torque

mm

2

AWG

mm

2

AWG

N·m

ldf·in

0.2/0.4 kW

0.75

18

2.5

13

-

-

0.75/1.0 kW

1.50

1

6

2.5

13

-

-

1.5/2.0 kW

2.5

13

6.0

10

1.4±0.2 12.39±1.8

Rated power

U, V, W terminals

Min

(solid/stranded)

Max

(solid/stranded)

Tightening torque

mm

2

AWG

mm

2

AWG

N·m

ldf·in

0.2/0.4/0.75/1.0 kW

0.75

18

2.5

13

-

-

1.5/2.0 kW

2.0

14

6.0

10

1.4±0.2 12.39±1.8

Type

16 core I/O signal cable size

Description

mm

2

AWG

Bare wire

0.2~1.5

24~16

Stripping or

terminal length

10mm

Tubular bare terminal

0.25~1.5

23~16

Tubular pre-insulated terminals

0.25~0.75

23~19

Motor type

Flange

size

(mm)

Cable cross-section of cores

Length

Motor power

cable

(With brake)

Motor

power cable

(Without

brake)

Encoder

cable

DSM-04L-0KWA/1-302

40

0.75+0.3 mm

2

0.75 mm

2

24AWG/

26AWG

3/5/10/

15

/20/30

m

DSM-06L-0KW2/4-302

60

DSM-08L/M-0KW8-302

80

DSM-13M-1KW0-202

130

1.3+0.5 mm

2

1.3 mm

2

DSM-13M-1KW5-202

130

2+0.5 mm

2

2 mm

2

DSM-13M-2KW0-202

130

Parameter

Description

Drive type

E530-EC0S-xKWx-x

Main power supply

0.2~1.0kW:1-phase 200~240V,-15%~+10%;

1.5kW~2kW

1)

:1-phase/3-phase 200~240V,

-15%~+10%; 50/60Hz,- 5%~+5%

Frame size

F2: 0.2kW/0.4kW; F3: 0.75kW/1.0kW; F4: 1.5 kW/

2.0kW

Operating environment

Indoor (no direct sunlight), no corrosive gas,

flammable gas, oil gas or dust.

Storage temperature (°C)

-20°C ~ +65°C

Transport temperature (°C) -20°C ~ +65°C

Relative humidity (RH)

0 ~ 90% (on-condensing)

Installation altitude (m)

<1000 m (without derating); 1000 m - 2000 m

(with derating), the derating is 1% for every

100m increasing.

Atmospheric pressure (kPa)

Atmospheric pressure range 86 kPa ~ 106 kPa.

Please contact the manufacturer if it exceeds the

range.

Degree of protection

IP20

Protective class

PC1

Degree of Pollution

PD2

Power grid type

TT/TN

Overload capacity

300%

Lifetime

40,000 hours (Average 20 hours / day, 80% load

at 30°C).

Operating temperature (°C)

Operation temperature:

0°C~55°C; (0°C~45°C, no derating; 45°C~55°C

derating as 80%, the derating is 2% for every 1°C

increasing), see the figure below:

Maximum surrounding air temperature is 55°C

(open type).

Mechanica

l Vibration

Operation

The vibration test in operation: test meets

standard IEC 61800-5-1, and the test method

according to sine vibration in IEC 60068-2-6.

10 Hz ~ 58 Hz: 0.075 mm deflection;

58 Hz ~ 200 Hz: 1 g acceleration;

Quantity of cycles: 10 per axis XYZ;

Sweep speed: 1 octave/min.

Storage/

Transport

ISTA1A

Mechanical shock

The shock test in operation: test meets standard

IEC 61131-2, and the test method according to

the half sine wave shock in IEC 60068-2-27.

15 g peak acceleration; 11 ms duration;

Quantity of cycles: 3 times per axis XYZ in both

positive and negative directions, totally 18 times.

Free fall

Operation

Not allowed.

Storage/

Transport

76 cm

Degree of over Voltage

According to IEC/EN 60664-1 standard:

1 - phase AC 220V: category II (IEC/EN 60664-1);

3 - phase AC 220V: category III (IEC/EN 60664-1)

Frame

size

Net weight

Gross weight

Package net weight

kg

lb

kg

lb

kg

lb

F2

0.77

1.71

1.06

2.34

0.28

0.63

F3

1.08

2.38

1.42

3.13

0.34

0.74

F4

1.60

3.54

2.01

4.43

0.40

0.89

Cabinet wall

Vertical installation

Not support horizontal installation

cabinet wall

10 mm

10 mm

10 mm

Air inlet

Air outlet

Air inlet Air inlet

Air inlet Air inlet Air inlet

Air outlet

Air outlet

Air outlet

Air outlet Air outlet

F2, F3

F4

cabinet wall

≥

40 mm

≥

100 m

m

≥

100 m

m

≥

100

m

m

≥

100 m

m

Front view

Back view

Side view

W

H1

L1

L2

D2

A

B

∅

5.5

5.5

∅

5.5

∅

12

10

6.5

A

H3

D1

B

H2

Main

dimensions

/mm

W

H1

H2 H3

D1

D2

Screw Screw torque Drill hole/mm

40

202 175 70 150 80

2/ pcs M5 , 3.0/ N.m L1: 190 L2: 20

60

202 175 70 150 80

3/ pcs M5 , 3.0/ N.m L1: 190 L2: 40

Front view

Back view

Side view

W

H1

L1

L2

A

A

B

∅

5.5

5.5

∅

5.5

∅

12

B

6.5

H3

D1

H2

D2

Items

General inspection

Regularly check the servo drive's screws, motor shafts, terminals, and

connections to the mechanical system for looseness and eccentricity, and

tighten the screws if necessary, as they may loosen due to vibration and

temperature changes.

Make sure that oil, water, metal dust or any foreign objects do not fall into

the servo drive, motor, control panel or fan as these can cause damage to

the equipment.

Inspection before operation

To avoid electric shock, be sure to connect the ground terminal of the

servo drive to the ground protection terminal of the control cabinet.

Before making any connections, disconnect the power and wait 5 minutes

for the capacitors to discharge or use a suitable discharge device.

Make sure all terminals are properly insulated.

Make sure all systems are wired correctly, otherwise equipment damage

and malfunction may result.

Visually inspect to make sure there are no unused screws, metal bars, or

any conductive or flammable material inside the drive.

Never put flammable objects on the servo drive or close to the external

regenerative braking resistor.

Make sure the emergency stop switch is off.

If an electromagnetic brake is used, please make sure that its circuit for

cutting off the power is normal and effective.

If necessary, use appropriate electronic filters to eliminate

electromagnetic interference.

Make sure the external voltage to the drive is correct.

Inspection during operation

When the motor is running, pay close attention to the encoder cable

connections for damage, wear, or overextending.

Check for abnormal vibrations and sounds during operation.

Make sure all parameters are set correctly.

When resetting the parameters, make sure that the drive is in the servo

stop state. Otherwise, malfunction may result.

Ensure correct operation when using relays.

Check the power indicator and LED display for any abnormality.

L2

Control Unit

Control

circuit

power

supply

Gate drive

Voltage

detection

Overcurrent

protection

Current

detection

CN

1

IO

Cooling Fan

Ύ

CN

2

CN

4

PHY

Encoder

ƚŚĞƌŶĞƚƉŽƌƚ

Servo drive

Diode stack

L1

L1

Regenerative option

P

Regenerative

TR

Charge

light

Relay

Short for internal

brake resistor

Current

detector

U

V

W

U

V

W

U

V

W

U

V

W

Servo motor

M

E

RA

B1

B2

B

Electromagnetic

brake

24V DC

N

BO

P

Control panel

CN3

PHY

EtherCAT

R

C

/ŶƚĞŐƌĂƚĞĚďƌĂŬĞ

ƌĞƐŝƐƚŽƌΎ

L2

Control Unit

Control

circuit

power

supply

Gate drive

Voltage

detection

Overcurrent

protection

Current

detection

CN

1

IO

Cooling Fan

CN

2

CN

4

PHY

Encoder

ƚŚĞƌŶĞƚƉŽƌƚ

Servo drive

Diode stack

L1

Regenerative option

P

Regenerative

TR

Charge light

Relay

Short for internal

brake resistor

Current

detector

U

V

W

U

V

W

U

V

W

U

V

W

Servo motor

M

E

RA

B1

B2

B

Electromagnetic

brake

24V DC

N

L3

BO

P

Control panel

CN3

PHY

EtherCAT

R

C

/ŶƚĞŐƌĂƚĞĚďƌĂŬĞ

ƌĞƐŝƐƚŽƌ

Main

dimensions

/mm

W

H1

H2 H3 D1

D2

Screw Screw torque Drill hole/mm

80

202 175 70 175

80

4 / pcs M5 , 3.0/ N.m L1: 190 L2: 60